Aeropro A604 User manual

1

Top Grade Air Powered Spray Gun A604

INSTRUCTION MANUAL

2018

Top Grade Air Powered Spray Gun

Model No.:A604 Http://www.aeroprotools.com

IMPORTANT:

Read this Instruction Manual carefully and understand it completely,

basic precaution should be strictly followed to prevent the damage to

the tool and injury to the operator. Retain this manual for further

reference.And you should pay more attention to the Technical Data.

2

Top Grade Air Powered Spray Gun A604

QUICK START GUIDE:

Description

Technical Data

Important Safety Instruction

Instructions for Operation

Maintenance/Storing

Troubleshooting/Repairs

Parts List

Description

Aluminum forged gun body with precise machined air cap set.

Stainless steel needle and nozzle accommodate a variety of coating.

Even better surface quality for spotless finish.

Ensure excellent painting results.

Great for Automobile finish painting

Technical Data

Feed Type:

Gravity

Standard of Nozzle:

Φ1.3mm

Optional Nozzle:

Φ1.3,1.5,1.7mm

Recommended air pressure:

2.0bar

Pattern Width:

180-260mm

Paint Capacity:

500cc

Air Consumption:

4.1~4.5cfm

Air Inlet

1/4

※Important Safety Instructions

1. For toxic vapors produced by spraying certain materials can create intoxication

and serious damage to health. Always wear safety glasses, gloves and

respirator to prevent the toxic vapor hazard, solvent and pointing paint coming into

contact your eyes or skin. (see fig 1)

3

Top Grade Air Powered Spray Gun A604

2. Never use oxygen, combustible or any other bottle gas as a power source or would

cause explosion and serious personal injury. (see fig 2)

3. Fluid and solvent can be highly flammable or combustible. Use in well-ventilated spray

booth and avoid any ignition sources, such as smoking, open flames and decrial

hazard. (see fig 3)

4.Disconnect tool from air supply hose before doing tool maintenance and during

non-operation, for emerge stop and prevention of unintended operation, a ball valve

near the gun to air supply is recommend.

5. Use clean, dry and regulate compressed air rated at 2.0bar, never exceed maximum

permissive operating pressure (see fig 4)

6. Never use homogenate hydrocarbon solvent, which can chemically react with

aluminum and zinc parts and chemically compatible with aluminum and zinc pats.

7. Never point gun at you and others at any time.

8. Before operating the tool, make sure all the screws & caps are securely tightened in case of leaking;

9. Before painting, make inspection for free movement of trigger and nozzle to insure tool can operate well.

10. Never modify this tool for any applications. Only use parts, nozzles and accessories recommended and

accessories recommended by manufactures.

※Operating Instructions

This tool applies to operate on clean, dry and compressed air at regulated pressure at 2.0bar.Too low or too

high pressure is not allowed.

Check and replace any damaged or worn parts on the tool, make sure the trigger and nozzle can operate well.

Connect the gun to air supply, fluid cap, container and air hose should be connected tightly with spray gun.

When painting, Grip the gun keeping perpendicular with spraying area then move it parallel for several times,

the trigger should be locked before the stroke ended. Keep the appropriate distance of 6-8 inches between

gun and raying area, according the atomization pressure and work demand. Just like the fig5 show.

Fig 5

4

Top Grade Air Powered Spray Gun A604

※Adjustment

The desired pattern, volume of fluid output and fine atomization can easily be obtained by regulating the

PatternAdjusting Knob, FluidAdjusting Knob andAirAdjusting Knob.

①Adjusting pattern: Turning Pattern Adjusting Knob to the right until tight will make spray pattern round, or

turning it left, will make spray pattern ellipse.

②Adjusting volume of fluid output: Turn the Fluid Adjusting Knob, clockwise will reduce the volume of

fluid output and counter-clockwise will increase fluid output.

③Adjusting air volume: Turning the Air Adjusting valve clockwise will reduce the air volume. And

counter-clockwise will increase the air volume.

※Maintenance

Pour remaining paint into other container and then clean paint passage and air cap. Spray a small amount

thinner to clean passage. Incomplete cleaning will cause adverse pattern sharp and particles. Clean other sections

with attached brush, soaked with thinner soft clothes.

※Caution

Never use the wire or other hard thing to dig nozzle, fluid needle, this will cause the damage of them. Never

immerse spray gun completely in thinner or solvent. When reassembly, always clean parts to prevent the sticking

of dust.

※Troubleshooting

The following chart lists common issues and solutions.Please read it carefully and follow all instructions closely.

WARNING!

Potential hazard that could result in serious injury or loss of life.

If any of the following symptoms appear while the tool is in use, turn it off and disconnect it from

the air supply immediately. Failure to heed this warning could result in serious personal injury.

Disconnect the electrical plug and air supply from the tool before making any adjustments.

Repairs must be performed by a qualified service technician only.

2

3

1

5

Top Grade Air Powered Spray Gun A604

Symptom

Problems

Solution

Fluttering or spitting

1. Material in container is litter.

2. Dry or worn Needle packing set.

3. Fluid nozzle loose or worn

1. Add material into container.

2. Lubricate or replace Needle packing

set.

3. Tighten or replace Fluid nozzle.

Pattern is arc.

1. Worn or loose Fluid nozzle.

2. Material build up on Air cap.

1. Tighten or replace Fluid nozzle.

2. Remove obstructions from holes,

but don’t use metal objects to clean it.

Pattern is not

Evenly spread.

1. Material build up on Air cap.

2. Fluid nozzle dirty or worn.

1. Clean or replace Air cap.

2. Clean or replace Fluid nozzle.

The center of Pattern

too narrow.

1. Material too thin or not enough.

2. Atomization air pressure too

high.

1. Regulate material viscosity.

2. Reduce air pressure.

Pattern width of

fan-sharp is not

enough.

1. Material too thick.

2. Atomization air pressure too

low.

1. Regulate material viscosity.

2. Increase air pressure.

Air leakage from air cap

when trigger is not

pressed

1. Air inlet valve or seat is

contaminated.

2. Inlet valve stem is stuck.

3. Air inlet valve or seat is worn or

damaged.

4. Air inlet spring is broken.

5. Inlet valve stem is bent.

1. Lubricate the inlet valve stem.

2. Clean the air inlet valve or seat.

3. Replace air inlet valve or seat.

4. Replace air inlet spring.

5. Replace inlet valve stem.

Fluid leakage from

packing nut

1. Packing nut is loose.

2. Packing is worn or dry.

1. Tighten, but do not restrict the needle

movement.

2. Replace or lubricate (non-silicone oil).

Excessive overspray

1. Atomization pressure is too high.

2. Work surface is too far.

2. Improper stroking (arcing, gun

motion are too fast).

1. Reduce the air pressure.

2.Adjust to proper distance.

3. Move at moderate pace, parallel to

work surface.

No spray

1. No pressure in gun.

2. Fluid control is not properly

opened.

3. Fluid is too thick or heavy.

1. Check air lines.

2. Open the fluid control.

2. Thin the fluid or change to pressure

feed system.

Note: For further repair information, please send to: sales@aeroprotools.com

6

Top Grade Air Powered Spray Gun A604

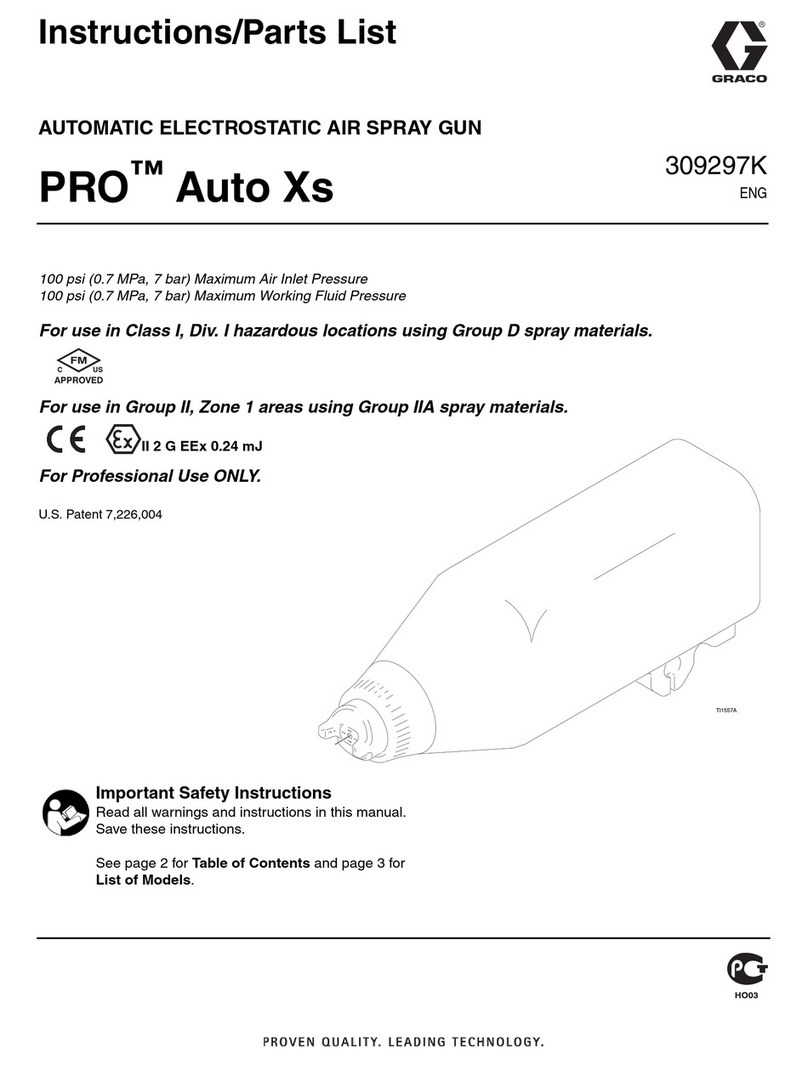

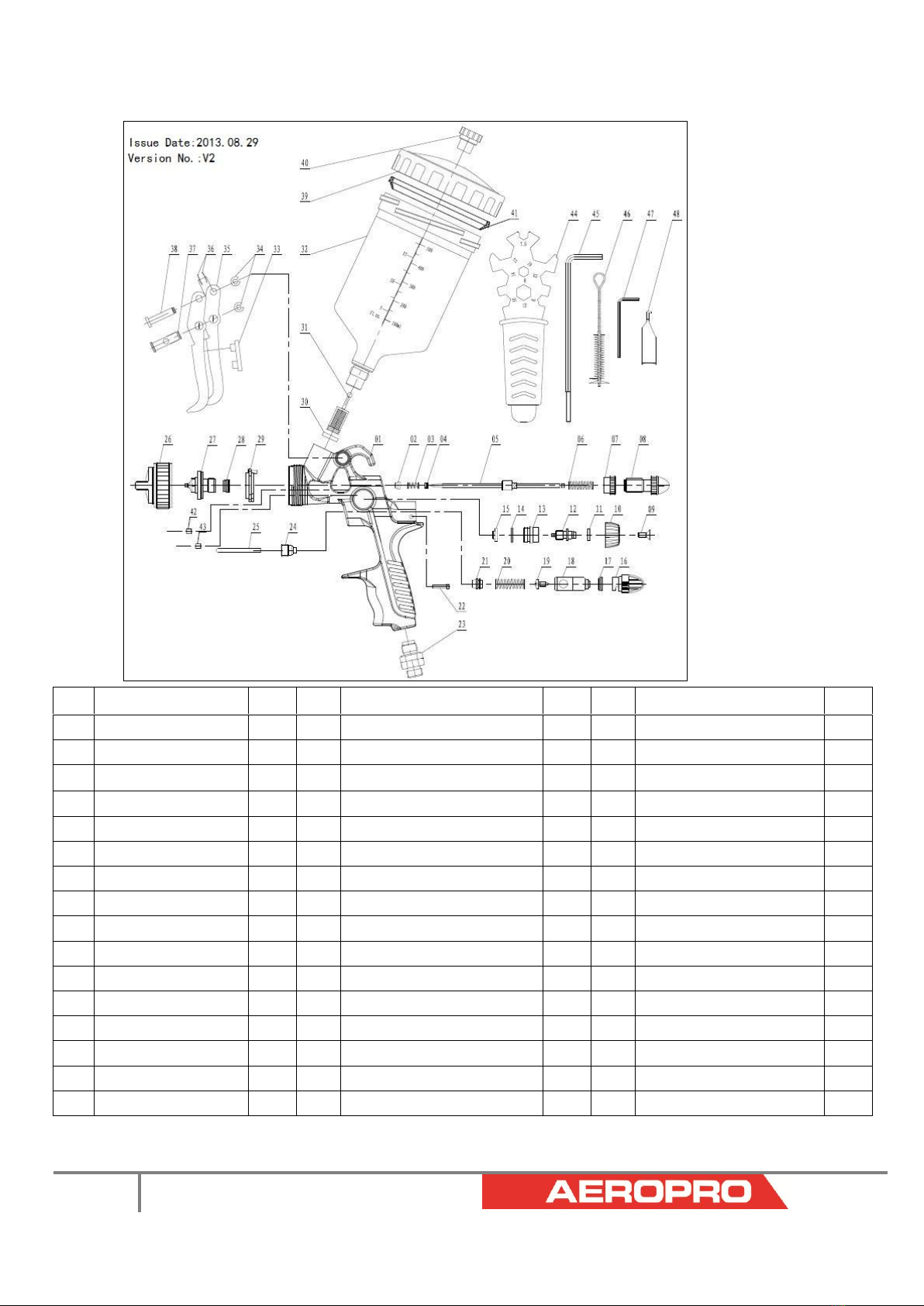

A604 Exploded view & Parts list

No.

Description

Qty.

No.

Description

Qty.

No.

Description

Qty.

1

Gun Body

1

17

Pressure Adj. Seal Ring

1

33

Trigger Washer

1

2

Needle Seal Ring

1

18

Regulator

1

34

Retainer Washer

2

3

Locking Spring

1

19

Self Tapping Screw

1

35

Trigger

1

4

Direction Screw

1

20

Switch spring

1

36

Curved Washer

2

5

Needle

1

21

Switch end cap

1

37

Trigger Pusher

1

6

Needle Spring

1

22

Position screw

1

38

Trigger Pin

1

7

Joint

1

23

Air inlet plug

1

39

Cup Lid

1

8

Fluid Adj. Knob

1

24

Switch seat

1

40

Ventilator Head

1

9

Phillips Screw

1

25

Switch pole

1

41

Cup Inner ring

1

10

Pattern Adj. Knob

1

26

Air cap

1

42

Pattern release end cap

1

11

Pattern Adj. washer

1

27

Nozzle

1

43

Fluid release end cap

1

12

Pattern Adj. Bolt

1

28

Nozzle sealing washer

1

44

Bull Hex wrench

1

13

Pattern Adj. Seat

1

29

Shunt Ring

1

45

Bovine Hex wrench

1

14

O-ring 11*1

1

30

Fluid Inlet sealing washer

1

46

Brush

1

15

Pattern Block

1

31

Filter

1

47

Hex Wrench

1

16

Pressure Adj. Knob

1

32

Cup

1

48

Hook

1

Note:If you need spare parts of this model, pls feel free to contact us or the distributor where you bought this

tool. Tks

Table of contents

Other Aeropro Paint Sprayer manuals