Aeros ANT-70 Instruction Manual

AEROS NANOLIGHT TRIKE

ANT-70

OWNER /SERVICE MANUAL

Wing: Fox-T

Engine: Octagon 190

Manufactured by:

AEROS Ltd Tel: (380 44) 455 41 20

Post-Volynskaya St. 5 Fax: (380 44) 455 41 16

UKRAINE http://www.aeros.com.ua

February 2019

2

3

CONTENTS

INTRODUCTION______________________________________________________________________4

1. GENERAL INFORMATION_____________________________________________________________5

2. LIMITATIONS______________________________________________________________________6

3. ULTRALIGHT & SYSTEMS DESCRIPTION_________________________________________________7

4. ULTRALIGHT ASSEMBLY PROCEDURES__________________________________________________8

5. PREFLIGHT INSPECTION OF THE WING__________________________________________12

6. ATTACHING THE WING TO THE TRIKE_________________________________________________12

7. FLIGHT PREPARATION______________________________________________________________14

8. ULTRALIGHT FLYING_______________________________________________________________16

9. EMERGENCY PROCEDURES__________________________________________________________18

10. ULTRALIGHT DE-RIGGING PROCEDURE_______________________________________________21

11. HANDLING SERVICE AND MAINTENANCE______________________________________________21

12. TRANSPORTATION AND STORAGE___________________________________________________23

SCHEMES

4

Introduction

Thank you for purchasing the Aeros ANT-70 nanolight trike.

Please read and be sure you thoroughly understand this manual before operating your ANT-70 trike. Be

sure you are thoroughly familiar with the ultralight and the contents of this manual before initial

operation.

Regular maintenance is required to keep your ultralight in a safe condition. Maintenance requirements

are outlined in the Wing maintenance and Trike maintenance sections of this Manual. Please reference

these sections to ensure your ultralight is maintained correctly.

The operating procedures outlined in this Manual are the result of Aeros knowledge and experience

gained since 1991.

Aeros data packages will be revised from time to time. It is therefore important that you visit us regularly

at http://www.aeros.com.ua

In case of any doubts or questions contact your local dealers or Aeros.

We wish you a safe and enjoyable flying career.

Aeros Ltd.

Symbols Abbreviations and Terminology

In this Manual:

Landing Approach Speed means the airspeed that allows control in turbulence, wind gradient or

sudden engine failure during landing.

Maneuvering Speed means the indicated airspeed above which the pilot may not make full or abrupt

control movements.

Stall Speed means the indicated airspeed at which an uncontrolled downward pitching motion of the

ultralight occurs or the forward control bar limit is reached.

Take Off Safety Speed means the airspeed that allows control in turbulence, wind gradient or sudden

engine failure during the climb following take-off.

Trim Speed means the indicated airspeed at which the ultralight remains in a stabilized condition

without pilot input.

Trike in this Manual means fuselage of the weight shift controlled powered aircraft with a power plant

and a tricycle undercarriage.

Ultralight in this Manual means weight shift controlled powered aircraft with tricycle base (trike) and a

flex wing.

Va means design maneuvering speed. This is the speed above which it is unwise to make full application

of any single flight control as it may generate a force greater than the aircraft's structural limitations.

VNE means the indicated airspeed that the ultralight is never to exceed.

Definitions

Definitions used in this Manual such as WARNING, CAUTION and NOTE are employed in the following

context:

WARNING

OPERATING PROCEDURES, TECHNIQUES, ETC. WHICH IF NOT FOLLOWED CORRECTLY, MAY

RESULT IN PERSONAL INJURY OR DEATH.

CAUTION

OPERATING PROCEDURES, TECHNIQUES, ETC. WHICH IF NOT STRICTLY OBSERVED, MAY

RESULT IN DAMAGE TO THE ULTRALIGHT OR ITS INSTALLED EQUIPMENT

NOTE

Operating procedures, techniques, etc. which are considered essential to highlight.

5

1. GENERAL INFORMATION

1.1 Trike

The ANT-70 trike is a one seat weight shift controlled nanolight trike. It is a light weight modification of

the ANT trike and designed to comply with sub 70kg aviation regulations. The regulations allow hang

glider pilots to fly sub 70kg aircraft on wheels with a simple powered endorsement, which means there is

no need to do a full ultralight licence.

It is fully complies with the concept of maximum portability – it can be folded up to fit in the back of

many cars. The wing is light and once packed can easily be carried on car roof racks.

There is Octagon 190 (2 stroke, 27 hp) engine to power the trike.

The base is attached to the wing by way of a hang bracket which allows the free movement of the trike

in pitch and roll by which control is affected.

The trike is equipped with adjustable pedals to allow for various size pilots.

ANT-70 trike

Empty weight with Octagon 190 engine, kg (lb) 35.4 (78)

Fuel tank volume, l (gal) 12 (3.17)

Starter type Manual actuation

Dimensions (folded, no prop), m (ft) L=1.35 (4.4), W=0.55 (1.8), H=0.95 (3.1)

1.2 Wing

There is a Fox 13 T wing to use with the ANT-70 trike.

Fox 13 T is specially designed to use with ANT-70 trike. It has been developed from our beginner hang

glider Fox 13 and has been reinforced and adapted for flying with ANT-70 nanolight trike.

Wing type Fox 13 T

Sail area, sq.m. (sq.ft.) 13 (140)

Wing span, m (ft) 8.65 (28.4)

Aspect ratio 5.75

Nose angle, deg 121

Stall speed, kmph (mph)* 37 (23)

Range of operating overloads, g +4 / -2

Max. clip-in weight, kg (lb) 155 (342)

Weight without bag, kg (lb) 25.5 (56)

* - with maximum load

1.3 Ultralight

The ANT-70 in combination with Fox 13T wing has proven to be an excellent combination to feel

simplicity and real pleasure of bird-like flying. The entire aircraft can be de-rigged and stored at home

with minimum time and effort without any tools required.

Wing type Fox 13 T

Engine type Octagon 190

Power, hp 27

Propeller type 2 blade

Ultralight empty weight, kg (lb) 61.35 (135.3)

Maximum pilot weight, kg (lb) 110 (243)

Max take-off weight, kg (lb) 180 (397)

Standard fuel tank, l (gal) 12 (3.17)

Max. airspeed, km/h (mph) 85 (53)

Min. airspeed, km/h (mph) 37 (23)

Fuel consumption at cruise speed, l/hour (gal/h) 4.5 (1.19)

Range of operating overloads, g +4 / -2

Climb rate, m/s (ft/min) 3.2 (630)

6

2. LIMITATIONS

2.1 General

The limitations section of this Manual outlines the various operating limitations, instrument function and

placards necessary for the safe operation of the ANT-70 with engine and standard equipment.

2.2 Airspeed Limitations

SPEED km/h mph COMMENTS

Vne (never exceed

speed) 90 56 Do not exceed this speed in any

operation

Va (maximum

maneuvering speed) 70 44 Do not make full or abrupt control

movements above this speed

2.3 Power Plant Limitations

2.3.1 Engine

The ANT-70 trike is equipped with Octagon 190 (2 stroke, 27 hp) air cooled engine with manually

actuated starter.

The trike may be equipped with other engines with similar characteristics.

WARNING:

THIS IS A NON-CERTIFIED AIRCRAFT ENGINE, THE POSSIBILITY OF ENGINE FAILURE EXISTS AT ALL

TIME. DO NOT OPERATE THIS ENGINE OVER DENSELY POPULATED AREAS. DO NOT OPERATE THIS

ENGINE OVER TERRAIN WHERE A SAFE, POWER OFF LANDING CAN NOT BE PERFORMED.

2.3.2 Fuel

Two-stroke engine in your trike requires using oil-petrol mixture in 1:40 ratio during regular usage and

1:33 when you run it in.

Premium petrol 95 (Ron) octane unleaded. Synthetic top-quality oil for 2-strokes engines.

2.4 Operational Limits

2.4.1 Centre of Gravity limits

Centre of gravity limits are not critical on the trike of a flex wing ultralight. Having the trike unit attached

to the wing with a hang bracket, variations of cockpit loading and fuel loading cannot influence the

ultralight’s balance. The ANT-70 is therefore not critical in regards to centre of gravity although the

distribution of load in the trike has an affect on the in-flight attitude of the ultralight.

2.4.2 Maneuvering Limits

All aerobatic maneuvers including spinning are prohibited.

Aerobatic maneuvers including stalls, stalled spiral descents and negative G maneuvers are not

permitted. These maneuvers put the ultralight outside the pilot control and put both the ultralight and its

occupant in extreme danger.

Do not pitch nose up or nose down more than 30 degrees from the horizontal.

Do not make high speed abrupt turns.

2.4.3 Bank Angle

Do not exceed 60 degrees of bank angle. In roll there is no stop for the control movement. When

performing the pre flight procedure check that the wing moves freely by lowering each wing to within

10 cm off the ground (on ground level).

ENGINE PERFORMANCE & LIMITATIONS

Engine Type Octagon 190

Take off RPM (Max 5 minutes), rpm 7500

Take off power, hp 27

7

2.4.4 Flight Load Factor Limits

Max positive maneuvering load factor: 4.0 G.

Negative load factors prohibited.

Load factors below 1.0 G to be avoided.

2.4.5 Operation Limits

The ultralight is only to be flown under visual flight rules (VFR), and the minimum equipment required to

operate under VFR conditions are an Air speed indicator, Altimeter and instruments that may be required

by the engine manufacturer.

Additional equipment may be required for some foreign operations.

2.4.6 Fuel Limitations

Tank capacity 12 liters.

2.4.7 Maximum Occupant Seating Limits

One occupant maximum allowed.

2.4.8 Minimum Pilot Weight

The micro light ultralight must only be flown solo. Minimum pilot weight shall not be less than 55 kg.

2.4.9 Other Limitations

Maximum Cross Wind - 2m/s

Maximum Wind Strength - 8m/s

Maximum Ambient Operating Temperature + 35 …-10 deg C

No person who is untrained or unqualified in weight shift controlled flight or, who is unfamiliar with the

wing and trike combination, should ever attempt to pilot the ultralight.

The effect of light rain on the wing can increase the stall speed. It is extremely important to maintain

speeds in excess of the take off and landing safety speeds when the wing is wet. If the ultralight has

been left out in the rain or heavy dew it is necessary to wipe the wing down prior to take off.

Continued operation in heavy rain is not recommended due to the abrasive effect of raindrops on the

propeller.

CAUTION

MOISTURE ON THE WING CAN INCREASE STALL SPEED AND SHOULD BE REMOVED PRIOR TO TAKE

OFF.

3. ULTRALIGHT & SYSTEMS DESCRIPTION

3.1 General

This section provides descriptions of the ultralight and its systems as well as methods of operation where

appropriate.

Information on the ultralight flight controls is detailed in this section, but it is mandatory that you receive

professional training prior to any solo flight.

3.2 Ground / Flight Control

Ground / flight Controls are as follows:

- Push left pedal = Taxi steering right

- Ignition switch forward = Switch on

- Control bar move left = Right turn

- Control bar move right = Left turn

- Control bar push out = Pitch up

- Push right toe = Throttle open

8

3.3. Control Panel

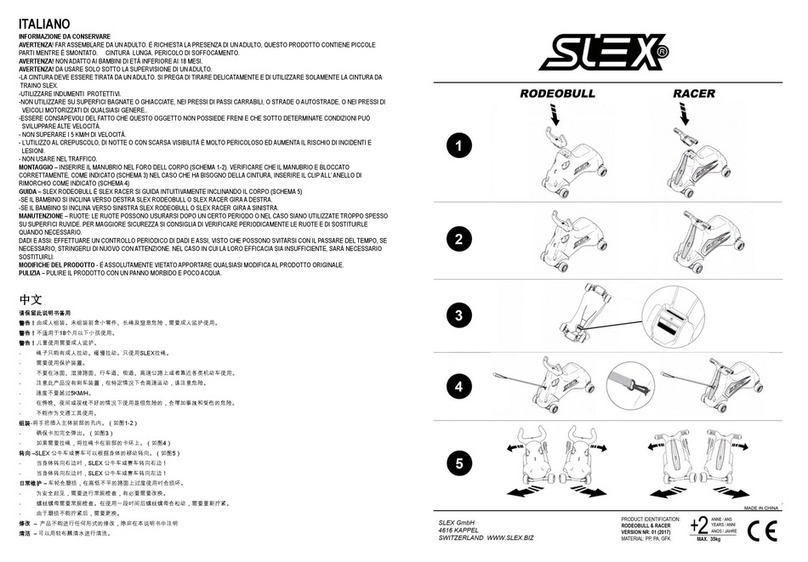

Figure 1

The control panel positioned on the left rest arm

(fig. 1) and may consist of:

-tachometer and hour meter (optional),

-key,

-ignition switch,

-start button,

-primer.

3.4 Occupant restraint Harness

The seat is fitted with a restraint harness system.

3.5 Engine

The power unit is Octagon 190 (2 stroke, 27 hp). The engine is fitted with a belt drive, which delivers

smooth thrust via a reduction drive.

3.6 Propeller

Manufacturer: KD Propeller

Type: 2 Blade Composite

Diameter: 1300 mm

The maximum propeller speed occurs when the engine RPM reaches 7500 RPM.

4. ULTRALIGHT ASSEMBLY PROCEDURES

4.1 Trike Assembly Procedure

The trike is easy to de-rig, pack-up and transport in pack-up bags. It comes in two bags – the trike and

the engine, with the propeller, the upper pylon and the front brace.

4.1.1 Unzip the bag with the trike (fig. 2 and fig. 3).

Figure 2 Figure 3

4.1.2 Rotate the front lower beam with the front wheel forward and fix it with the bolts and butterfly

nuts. Tighten the bolts with their eccentric arms. Secure them with safety rings (fig. 4 and fig. 5).

9

Figure 4 Figure 5

4.1.3 Detach the left landing gear axle-arm from the support and rotate it rearwards. Detach the left

forward landing gear strut from the Velcro strap (fig. 6).

Figure 6 Figure 7

4.1.4 Using quick-pins attach the left forward landing gear strut to the front bracket (fig. 7) and connect

the left landing gear axle-arm with the left forward landing gear strut (fig. 8).

Figure 8 Figure 9

4.1.5 Repeat the same procedure for the right landing gear leg. Note that the right forward landing gear

strut is already attached to the front bracket. Remove the support before.

Remove the protection pad with Velcro from the lower beam.

4.1.6 Attach landing gear bracing cables as shown on the figure 9.

10

Figure 10

4.1.7 If your trike is equipped with “big foot”

wheels attach them now as shown on the figures

below. Install the wheel (fig. 10), screw the bolt in.

Tighten the bolt with its eccentric arm (fig.11).

Install the safety ring (fig. 12).

If your trike has standard wheels simply skip this

paragraph and proceed to the next one.

Figure 11 Figure 12

4.1.8 Open the bag with the engine. Mount the engine on the trike by installing two bolts: upper one and

lower one. Tighten butterfly nuts and secure them with safety rings (fig. 13). Tighten the bolts with their

eccentric arms (fig. 14).

Figure 13

Figure 14

4.1.9 Mount the control panel by installing the mounting plate in to the corresponding pocket. Fix the

control panel with Velcro (fig. 15). Fix the electric wiring with Velcro as shown on the figure 16.

11

Figure 15 Figure 16

4.1.10 Install the throttle rod. Feed the throttle rod end through the rod end stop and position it in place

as shown on the figure 17.

Figure 17 Figure 18

4.1.11 Connect the fuel line with the quick connector (fig.18).

Figure 19

Figure 20

4.1.8 Install the main upper pylon and fix it temporarily with the lower bolt, so that the main upper pylon

can rotate (fig. 19). After attaching the wing to the trike you will need to fix the main upper pylon with

two bolts, tighten butterfly nuts and secure them with safety rings and tighten the bolts with their

eccentric arms.

4.1.9 Install the front upper brace, attaching it first to the main upper pylon (fig. 20) and then to the

front lower beam (fig. 21).

12

Figure 21 Figure 22

Figure 23 Figure 24

4.1.10 Attach the kickstarter handle to the main pylon as shown on the figures (fig. 22 and fig. 23).

4.1.11 Install the propeller making sure that the logo is facing rearward (fig. 24). Tighten the propeller

bolts.

Now your trike is ready for attaching the wing.

4.2 Wing Assembly Procedure

The wing assembly procedure and all information regarding the wing are written in a wing Manual.

Please read it thoroughly and make sure it is clearly understood.

5. PREFLIGHT INSPECTION OF THE WING

Conduct preflight inspection of the wing before attaching it to the trike as written in a wing Manual.

The ultralight preflight inspection is written in section 7. FLIGHT PREPARATION

6. ATTACHING THE WING TO THE TRIKE

6.1. Check that the ignition switch and the key are in off position. Install the wing mount support on the

lower pylon as shown on the figures below (fig. 25 and fig. 26).

13

Figure 25 Figure 26

6.2 Position the wing on its control frame, facing into the wind, with the nose on the ground.

6.3 Disconnect the lower part of the front brace tube from the bracket on the lower pylon. Hold down the

main pylon of the trike and rest the lower end of the front brace tube on the pilot’s sit.

6.4 Wheel the trike behind the wing. Lift the control frame of the wing up and rest the base bar on the

wing mount support. Fasten straps of the mount bracket around the base tube (frig. 27).

Figure 27 Figure 28

6.6 Lift the nose of the wing up until high enough to connect the hang bracket of the wing to the main

pylon of the trike. Insert the heart bolt, tighten the nut firmly and secure with a safety ring (fig. 28).

Figure 29

6.7 Connect the backup loop so that it passes

over the keel, around the kingpost and back to

the pylon. Tighten the nut and secure with a

safety ring (fig. 29).

6.8 Install the nose cone of the wing by applying

the top Velcro first then gently tension over the

nose plates and attach the Velcro to the

undersurface of the wing.

14

Figure 30 Figure 31

6.9 Sit in the pilot’s seat. Undo straps around the base tube. Take a firm grip on the base tube and lift it

all the way up until you will be able to attach the front brace tube back in position using the quick pin

(fig. 30).

6.10 Go to the back of the trike. Install the clamp bolt of the main pylon in place, tighten it and secure

with a safety ring. Check that all clamp bolts are tightened and secured with safety rings (fig. 31).

6.11 Remove the wing mount bracket from the lower pylon.

Figure 32

6.12 Park the ultralight crosswind; the wingtip

facing the wind has to be lowered and the base

tube has to be secured to the front brace tube

(fig. 32).

7. FLIGHT PREPARATION

7.1 General

Prior each flight depending on the purposes of flight it is necessary to work out the flight task:

- prepare flight maps and study the flight conditions;

- study meteorological conditions at the departure airfield, on course and at the arrival airfield;

- estimate the possibility of accomplishment the flight task;

- proceed with all necessary formalities which are relative to given flight;

- estimate the necessary fuel state;

- conduct complete preflight inspection of the ultralight.

WARNING

NO ATTEMPT SHOULD BE MADE TO FLY THE ULTRALIGHT WITHOUT APPROPRIATE ULTRALIGHT

FLIGHT TRAINING WITH AN APPROVED INSTRUCTOR.

15

7.2 Complete Ultralight Pre-Flight inspection

A full pre-flight inspection should precede every flight you make, not just the first flight of the day.

Daily inspections as outlined in the Engine Operator’s Manual should be carried out in conjunction with

the follow inspections.

WARNING

ENSURE THAT THE IGNITION SWITCH AND THE KEY ARE OFF PRIOR TO INSPECTION.

7.2.1 Trike Pre-flight Inspection

- No leaks from fuel system and engine.

- Fuel filter clean and operational.

- Sufficient fuel for flight.

- No splitting, denting or delaminating of the propeller.

- Propeller hub assembly secure and tie wired.

- No cracking in tire treads, or evidence of cracking around the rim. Wheels are secured.

- No bolts bent, fractured, no evidence of corrosion.

- Electrical system secure and operational.

- Throttle operation. Verify free and full movement.

- Seat belt attachments secure.

- All engine components secure - air filter, muffler, plug leads.

- Mechanical components. Rotate propeller and observe for noise or excessive resistance.

7.2.2 Wing Pre-flight Inspection

The complete preflight inspection of the wing is outline in the wing Manual.

7.2.3 General inspection of complete ultralight.

Check that the hang bolt and hang bracket are secure.

Check that the back up strap is secure.

Check that there is enough fuel to complete the flight.

7.3 Before Starting Engine

NOTE

Your trike is carefully test flown at Aeros factory. However the brake-in procedure of the engine is rather

continuous and has not been finished. It needs about 10 flying hours for the brake-in to be completed.

During this period it is forbidden to use maximum power, except for very short time during take-off.

Good braking-in will prolong the life of your engine.

Safety is everyone’s business. Included are only some important safety tips. Keep a good lookout, be

thoughtful and always show your intentions prior to starting.

Prior to flight a thorough pre flight inspection of the ultralight should be carried out. Details of the pre

flight inspection are shown earlier in this section. Make sure all engine controls are operative and you

understand the on/off positions of the throttle and ignition. These controls are readily accessible and you

must be able to operate them instinctively without hesitation.

The ignition switch forward is for ”on” and rearward is for ”off”. It disables the start button.

CAUTION

BEWARE OF LOOSE STONES IN THE RUN UP AREA. LOOSE STONES CAN BE SUCKED UP BY

THE PROPELLER AND CAUSE SEVERE PROPELLER DAMAGE IN A VERY SHORT TIME. RUN

UPS ARE BEST CONDUCTED ON A CLEAR SURFACE OR ON GRASS, NEVER ON GRAVEL

Never run the engine on the ground with the propeller turning unless you are doing so in a

run up area and can observe anyone or anything entering the danger area. It is

recommended that the engine not be run for any long periods whilst stationary on the

ground. Possible damage to the engine may occur due to overheating.

Before starting your engine you should read and be familiar with the engine manual.

16

7.4 Fuelling

Fuel flow is from a single fuel tank fitted with a self-venting tube.

Never refuel if fuel could be spilled on hot engine components. Use only safety approved fuel containers.

Never transport fuel in an unsafe manner.

The fuel system has an in-line fuel filter. This filter can be easily disassembled for cleaning and inspection

Fuel tank capacity is 12 liters.

A fuel gauge (a measuring tube) is located on the right side along the sit frame. Its purpose is to provide

the pilot with a visual indication of the quantity of remaining fuel.

WARNING

ENSURE THE ULTRALIGHT IS EARTHED TO AVOID STATIC DISCHARGE IGNITING FUEL DURING THE

REFUELLING OPERATION

7.5 Helmet Recommendation

The open cockpit of the ANT exposes the pilot to the elements during flight and exposes him to objects

outside of the ultralight in an emergency situation.

Helmet and eye protection are recommended to protect the pilot from precipitation, strike by insects.

Helmet is also recommended for risk reduction during an emergency landing of the ultralight. The helmet

recommended for use in the ultralight is that certified for air sports.

8. ULTRALIGHT FLYING

8.1 Starting the engine

All controls should be checked with the ignition OFF.

CAUTION

REMEMBER TO CLEAR PROP!

The engine should be started with the pilot in the seat.

The follow procedure should be used:

- Hand and foot throttle off.

- Turn the key switch on.

- Switch ignition ON.

- Press the primer three times (or until the fuel volume is filled) unless the engine is hot.

- Check visually that the propeller area is clear and call “Clear Prop” out loud.

- Pull on the start handle. If the engine refuses to start, switch off the ignition before investigation.

- When the engine starts, increase the engine RPM to a little above idle.

- Warm up the engine for 3 minutes.

Keep an ultralight log and enter any unusual engine behavior. Do not fly unless you have corrected a

given problem and recorded the correction in the log.

8.2 Taxiing

Taxiing in normal conditions is fairly easy.

The control frame should be positioned so that it is in the approximate position for normal trim speed.

The pilot’s feet actuate steering on the ground. Left turn occurs when the right footrest is pushed

forward.

Right turn occurs when the left footrest is pushed forward.

NOTE

Control sense for turning is opposite to that of a conventional three axis ultralight.

17

When taxiing in strong wind conditions the follow procedures apply:

· Head Wind conditions require the nose of the wing to be lowered just below the trim position.

· Down Wind conditions requires the nose of the wing to be raised just above the trim position.

· Cross wind taxiing requires the upwind tip to be lowered.

8.3 Before take off

Before flight a full-throttle check is to be carried out. During this operation the pilot must be seated in the

cockpit and prepared to switch off the ignition at very short notice if an emergency should arise.

WARNING

NEVER LEAVE YOUR ULTRALIGHT UNATTENDED WHILE THE ENGINE IS RUNNING.

CAUTION

BEWARE OF LOOSE STONES IN THE RUN UP AREA. LOOSE STONES CAN BE SUCKED UP BY

THE PROPELLER AND CAUSE SEVERE PROPELLER DAMAGE IN A VERY SHORT TIME. RUN

UPS ARE BEST CONDUCTED ON A CLEAR SURFACE OR ON GRASS, NEVER ON GRAVEL.

8.4 Take Off

The trike has a neutral static balance allowing a safe take-off that is controllable under all suitable flying

conditions.

Take off should be made on full power.

During take-off, the control bar should be held in the forward position with the wing level. Accelerate

smoothly to the take off safety speed.

When the ultralight reaches the takeoff safety speed it lifts up and the trike rotates quickly on the main

wheels. As the ultralight leaves the ground the control bar must be eased back to the trim position to

maintain takeoff safety speed.

Maintain your engine in top condition and assume it’s going to stop running at any time. Leave yourself a

way out for an unexpected engine failure.

Never fly your ultralight at locations, airspeeds, altitudes, or under any circumstances from which a

successful engine-off landing cannot be attempted.

8.5 Climb

Initial climb out should be made on full power for maximum take off weight. Once climb is established

power should be reduced. A minimum of takeoff safety speed should be used. Avoid pitching the nose of

the ultralight too high to the horizon. Very steep climbs are dangerous and can result in a stall followed

by a severe pitching of the nose forward.

WARNING

NEVER STALL THE ULTRALIGHT WITH THE NOSE PITCHED UP BEYOND 30 DEGREES.

MANOEUVRES BEYOND THIS ANGLE ARE DANGEROUS AND CAN RESULT IN A TAIL SLIDE FOLLOWED

BY A SEVERE TUMBLE.

8.6 Cruise

When the desired flight altitude is reached the ultralight may be leveled out and throttle reduced to that

required to maintain level flight.

CAUTION

HIGH-ANGLE CLIMB-OUTS NEAR THE GROUND SHOULD BE AVOIDED.

18

8.7 Descent, Approach and landing

Landing should always be into wind with a long straight approach.

Approach to the airstrip can be made with or without power, but in any case the airspeed should be

maintained above the nominated approach speed.

The ultralight should be flown on final approach at or above the nominated safety speed. The additional

airspeed allows for wind gradient, and to provide greater controllability in rough air close to the ground.

Maintaining airspeed on final is very important for engine-off landings, allowing a margin for round out

before touch down.

The trike is designed to land with the rear wheels touching down slightly before the nose wheel. Once

firmly on the ground aerodynamic braking may be achieved by pulling in the control bar.

NOTE

After a hard landing, your ultralight must be completely checked.

8.8 Cross Wind Landing and Take Off

Pilots with less experience should avoid landing or taking off with high crosswind components, as skills do

not always match the capabilities of the ultralight. Crosswind landing or take off with low wind

components up to 1 m/s are quite safe and controllable, even to the inexperienced pilot.

The nominated approach speed of 51 km/h should be increased to 55 - 60 km/h when landing in cross

wind conditions.

After touchdown in cross wind conditions the relative airflow over the wing will become increasingly span

wise (From tip to tip) as the ultralight slows down. The upwind tip should be lowered slightly (the amount

depends on the wind strength), and the undercarriage wheels will retain firm contact with the ground.

Take off procedure is unchanged for the nominated crosswind limit. The upward may need to be lowered

at the start of the take off procedure in higher cross winds.

8.9 Go-Around Landing

During a situation where a go-around landing is required, normal take off power and procedures should

be used.

8.10 Stopping the Engine

To stop the engine after a period of running, the ignition should be switched off at idle. If the engine has

been running under full power, allow the engine to cool at idle before switching off.

8.11 After Landing / Securing

After landing and when in the parking switch the ignition off and set the key in off position. Park the

ultralight crosswind; the wingtip facing the wind has to be lowered and the base tube has to be secured

to the front brace tube.

9. EMERGENCY PROCEDURES

9.1 General

This section contains operating procedures for flight and system emergency conditions that are essential

for the continued safe operation of the ultralight.

Always maintain correct airspeed and altitudes, especially in the aerodrome traffic circuit operation.

Never fly in uncertain weather conditions and always fly within your proven ability. Be sure only to extend

your capabilities under planned training situations.

Carry out safe airmanship whilst flying and be aware of possible emergency landing areas along your

flight path. If possible check these areas from the ground as you enter the airfield or flying site. This

19

technique is for safety reasons as engines are susceptible to stopping, no matter how reliably

manufactured or maintained.

Keep a good lookout for other ultralight, always be thoughtful and show your intentions.

Remember that the manufacturer cannot foresee all conceivable circumstances. Particular circumstances

such as multiple or unanticipated emergencies, adverse weather etc may require modification to these

procedures. A thorough knowledge of the ultralight and its systems is required to analyze the situation

correctly and to determine the best course of action.

Maximum maneuvering speed is 70 km/h.

Best glide speed (with maximum load) is 50 km/h.

9.2 Engine Failure on Take Off

10.2.1 Engine Failure on Take Off Run

If the engine fails on take off run before the ultralight has lifted off proceed as follows:

- pull the control bar in to prevent the ultralight lifting from the ground;

- use pedals to maintain the ground run direction, avoid direct collision with obstacles;

- switch off the ignition.

10.2.2 Engine Failure on Climb Out

If your engine fails on climb out before you have reached 5 meters altitude, land straight ahead. Proceed

as follows:

- pull the control bar in further than the trim position to prevent the ultralight from loosing airspeed;

- Land in accordance with section 6.7 of the Manual. Avoid direct collision with obstacles.

- switch the ignition off.

9.3 Engine Failure at Height

If the engine stops while operating at cruise or full power when the ultralight is well clear of the ground,

make sure that ignition is on.

If your engine fails in flight, do not attempt to restart the engine unless one of these items is found to be

incorrect and is able to be rectified. Relax and maintain control whilst concentrating on correct forced

landing techniques.

9.4 Full Power Engine Shutdown (In Flight)

If the throttle should jam full open in flight proceed as follows:

Maintain Control.

Get height with engine at full power, adjust height and ground position to improve the outcome of

forced landing.

Increase airspeed to keep the climb angle less than 30 degrees above the horizontal.

Switch off ignition.

Prepare for forced landing, section 9.5.

9.5 Forced Landing

Proceed as follows:

Maintain control and airspeed - nominated approach speed.

Close the throttle.

Switch the ignition off.

Tighten the seat belts.

Carry out final approach and landing as closely as possible to normal power off landing procedure.

9.6 In Air Engine Fire

For fire occurring whilst in flight, the initial procedure would be to maintain control of the ultralight and

evaluate the extent of the fire. This emergency is unlikely to occur but to avoid any further problems, use

common sense and land the ultralight safely. Proceed as follows:

20

Maintain Control

Ignition off

Forced Landing

After landing release seat belt

Evacuate ultralight.

9.7 On Ground Engine Fire

If fire occurring whilst on the ground proceed as follows:

Maintain control and use remaining speed to clear people, others ultralights and buildings.

Close the throttle.

Turn the ignition off.

After stopping release seat belt.

Evacuate the ultralight.

9.8 Propeller Damage

The indication of propeller damage is usually felt by extreme vibration and lack of thrust. Proceed as

follows:

Maintain Control and airspeed.

Close the throttle.

Turn the ignition off.

Prepare for forced landing.

This problem may be avoided if precautions are taken prior to take off. Inspect the airstrip or ground you

are going to use as your take off area for sticks, rocks or any debris that may be flicked up by the tires

and sucked through the propeller.

Ensure that all items carried on board (such as cameras and sunglasses) are secured so they are

not able to come loose and pass through the propeller.

WARNING

AT FULL ENGINE RPM THE TIP OF THE PROPELLER IS SPINNING AT SPEEDS IN EXCESS OF 650

KILOMETERS PER HOUR.

EVEN SMALL OBJECTS CAN CAUSE SIGNIFICANT DAMAGE TO THE PROPELLER.

9.9 Sail Damage

If you encounter damage to the sailcloth during flight, the first procedure is to maintain control of the

ultralight. If the sail damage is not changing the flight characteristics of the ultralight, land at the nearest

landing field to inspect the damage.

9.10 Stalls

In practice, in level flight it is difficult to induce a nose down stall of the ultralight, although it greatly

depends on the wing type you fly. The beginning of stall is indicated by a significant increase in control

bar loads.

Recovery from a mild stall is very gentle, whether power is on or off. Recovery is quick, with height

loss of less than 20 meters. A stall would have to be forced violently, to induce a danger.

Never stall with the nose pitched up too high. This is a dangerous maneuver and can result in a tail slide

followed by a severe tumble.

9.11 Spins and Spiral Descents

Deliberate spinning is prohibited.

A spiral dive may develop after a stall if the bar is maintained at the forward limit and a large roll rate is

allowed to develop. If this condition is not corrected it will lead to large and increasing roll attitudes

(beyond the 60 degree limit). Increasing attitude, increasing speeds and large control bar feed back

forces will occur. Incipient spiral dives can be terminated at any time by rolling wing level.

Table of contents