DEVIATE Highlander II User manual

1

Deviate Highlander II User Manual v1.2 12.12.23

User Manual:

2023

32

Deviate Highlander II User Manual v1.2 12.12.23Deviate Highlander II User Manual v1.2 12.12.23

SAFETY INSTRUCTIONS

BICYCLE SAFETY

As with all mechanical components, the bicycle is subjected to wear and high stresses.

Different materials and components might react to wear or stress fatigue in different ways.

If the design life of a component has been exceeded, it may suddenly fail, possibly causing

injuries or death to the rider. Any form of crack, scratches, or change of colouring in highly

stressed areas indicate that the life of the component has been reached and it should be

replaced. Additionally, after a crash or impact even without visible damage – affected

components should be replaced or a professional opinion should be sought.

For composite components for example the frame, impact damage is often invisible to the

user. In the event of any impact you should stop using the bicycle immediately and return

affected components to the manufacturer for inspection. Failure to do so may result in

catastrophic failure and injury or death.

USAGE

This product is intended for off road use on trails and tracks. It is not designed for use on

Downhill racing and tracks. The use of this product in downhill bike parks including jumps or

drops is not recommended. The use of any bicycle on or off-road, even the best circumstances,

is dangerous and may result in injury or death. Correct set-up and maintenance is your

responsibility and helps reduce the risk of injury, death, or damage to your bicycle.

ENVIRONMENTAL

High or low temperature exposure may result in damage to components. The safe operating

temperature is between -10°C and +50°C.

PROTECTIVE EQUIPMENT

The use of a bicycle helmet and gloves are recommended as well as other protective gear

appropriate to the terrain – for example knee guards, elbow guards or a spine protector.

WARNING

TABLE OF CONTENTS

SAFETY INSTRUCTIONS ......................................... 3

Bicycle Safety .............................................................3

Usage ...................................................................3

Environmental .............................................................3

Protective Equipment .......................................................3

Suspension ...............................................................4

Pre-ride Checks............................................................4

Entrapment ...............................................................4

Luggage and Child Seats or Carrier ...........................................4

Permissible Weight .........................................................4

Public Roads ..............................................................4

ASSEMBLY .................................................. 5

Parts Specific Standards .....................................................5

Seat Post Dropper Cable ....................................................5

Top Tube Cable Guides .....................................................5

Shock Fitment .............................................................6

Bottom Bracket Washer .....................................................6

MAINTENANCE ............................................... 6

Service Intervals ...........................................................6

Bolt Torque Summary .......................................................7

PARTS LIST ...........................................................7

Quick Reference Spares .....................................................7

DIAGRAMS ...........................................................8

Front Triangle - Diagram .....................................................8

Front Triangle - Parts Table ...................................................9

Rear Triangle - Diagram ....................................................10

Rear Triangle - Parts Table ..................................................11

Rocker Diagram ..........................................................12

Rocker Parts Table ........................................................13

WARRANTY ..........................................................14

Warranty Exclusions .....................................................14-15

Functioning of Warranty ....................................................15

5

Deviate Highlander II User Manual v1.2 12.12.23

4

Deviate Highlander II User Manual v1.2 12.12.23

SAFETY INSTRUCTIONS (CONTINUED)

SUSPENSION

Suspension set-up and adjustment should be carried out according to the manufactures

recommendations. Please refer to the suspension manufacturers product instructions.

PRE-RIDE CHECKS

All bolts and fasteners should be checked before according to the recommendations in the

Maintenance section of this manual or the manufactures recommendations. Brake function and

tyre pressure, wheel fitment and the functioning of the suspension should be checked before

every ride. Additionally, normal functioning of pedals and drivetrain should be checked.

ENTRAPMENT

There is a risk of trapping body parts during maintenance and normal use. Care should be

taken when maintaining moving parts and appropriate protective equipment should be worn.

During normal use care should be taken to prevent loose clothing catching in the moving

parts.

LUGGAGE AND CHILD SEATS OR CARRIER

The bicycle is not suitable for the fitment of any luggage carrying device or any child seat or

carrier.

PERMISSIBLE WEIGHT

The total permissible weight of a rider including gear is 120kg.

PUBLIC ROADS

If used on public roads it is your responsibility to ensure your bike is legal and roadworthy

SEAT POST DROPPER CABLE

Scan below for video guidance

TOP TUBE CABLE GUIDES

There are a number of cable clamps along

the length of the top tube. These provide

clamping for the cables, but also serve as

tool fixing points, Di2 or additional bottle

mounting.

ASSEMBLY

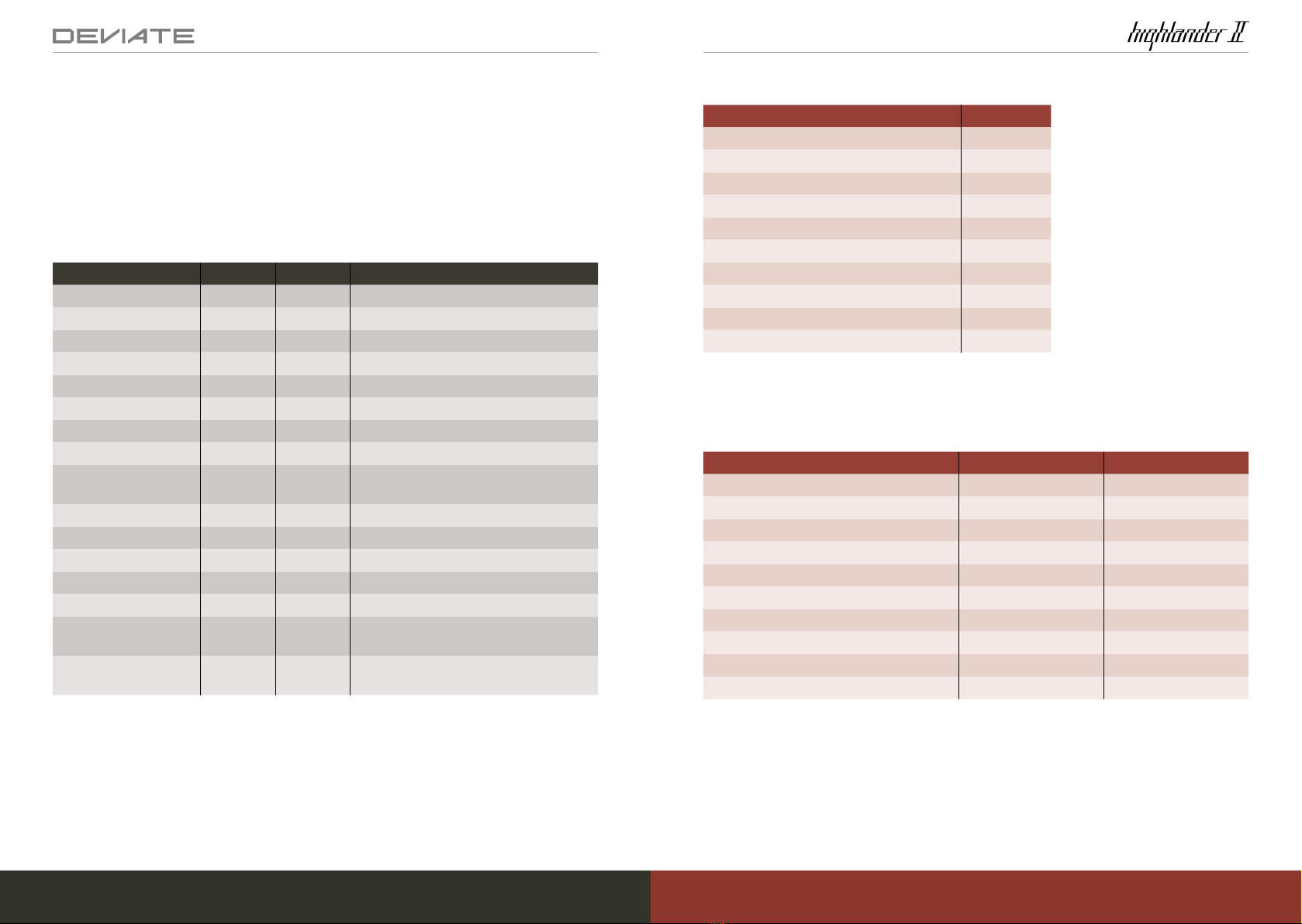

PARTS SPECIFIC STANDARDS

Interface Specication

Fork Compatibility 29” 160mm 44/42mm offset

Bottom Bracket 73mm BSA Threaded

Headset ZS44/ ZS44/28.6 upper and a ZS56/40 lower headset

cup

Chainline 52mm (any deviation from this will cause increased

idler wear)

Chain Length 126 links (widely available, no need to join chains)

Max Chainring Size 36t round (oval chainrings may fit depending on

design but check for interference before riding)

Shock Size Metric 210*55mm (coil or air)

Shock Hardware Front: 40*8mm | Rear: Eyelet bushing

Shock Average Leverage Ratio 2.54 mm/mm

Brake Mount Post Mount 180mm (Max 203mm Disc Size Rear)

Seatpost Compatibility Internal dropper routing with internal cable routing.

34.9mm, Minimum Insertion Depth: 150mm.

Maximum Insertion Depth: Medium:- 300mm,

Large:- 330mm, XL:- 360mm

Seat Collar 38.5mm (supplied with frame)

Max Tyre Size 2.8”

Deviate Cycles recommends this bike is assembled by a competent bike mechanic.

76

Deviate Highlander II User Manual v1.2 12.12.23Deviate Highlander II User Manual v1.2 12.12.23

BOTTOM BRACKET WASHER

Provided in the box is a BB washer (part number 14 on Front Triangle Assembly). Please

ensure this is fitted when installing the BB between the frame and BB. It replaces the 2.5mm

spacer found with BB’s to achieve a 52mm chainline. Additional spacers may be required for

certain BB’s.

MAINTENANCE

SERVICE INTERVALS

Action Every Ride 50hrs Notes

Clean/Lube Train • Not wax chain lubricants

Check Tyre Pressures •

Clean Mud/Debris •

Check Brake Function •

Clean Stanchions •

Check Brake Pad Wear •

Check Shock Pressure • See manufacturer guidelines (25-30% sag)

Check For Loose Bolts • Refer to diagrams on page (xxx)

Lube Grease Ports •See diagrams for port locations

(Pages 10, 12)

Check Tyre Wear •

Check Spoke Tension •

Check Drivetrain Wear • Replace chain before 0.75% wear

Check Bearing Wear • Check for play in pivots and idler

Rebuild Linkages As Required

Fork Service Refer to fork manufacturers

recommendations

Shock Service Refer to shock manufacturers

recommendations

GREASE PORTS

After locating the grease ports (see diagrams on pages 10 & 12) use a Deviate Cycles Dualco

grease gun to insert Peaty’s speed grease into the specified port. Ensure any excess grease is

cleaned and removed prior to using the bike.

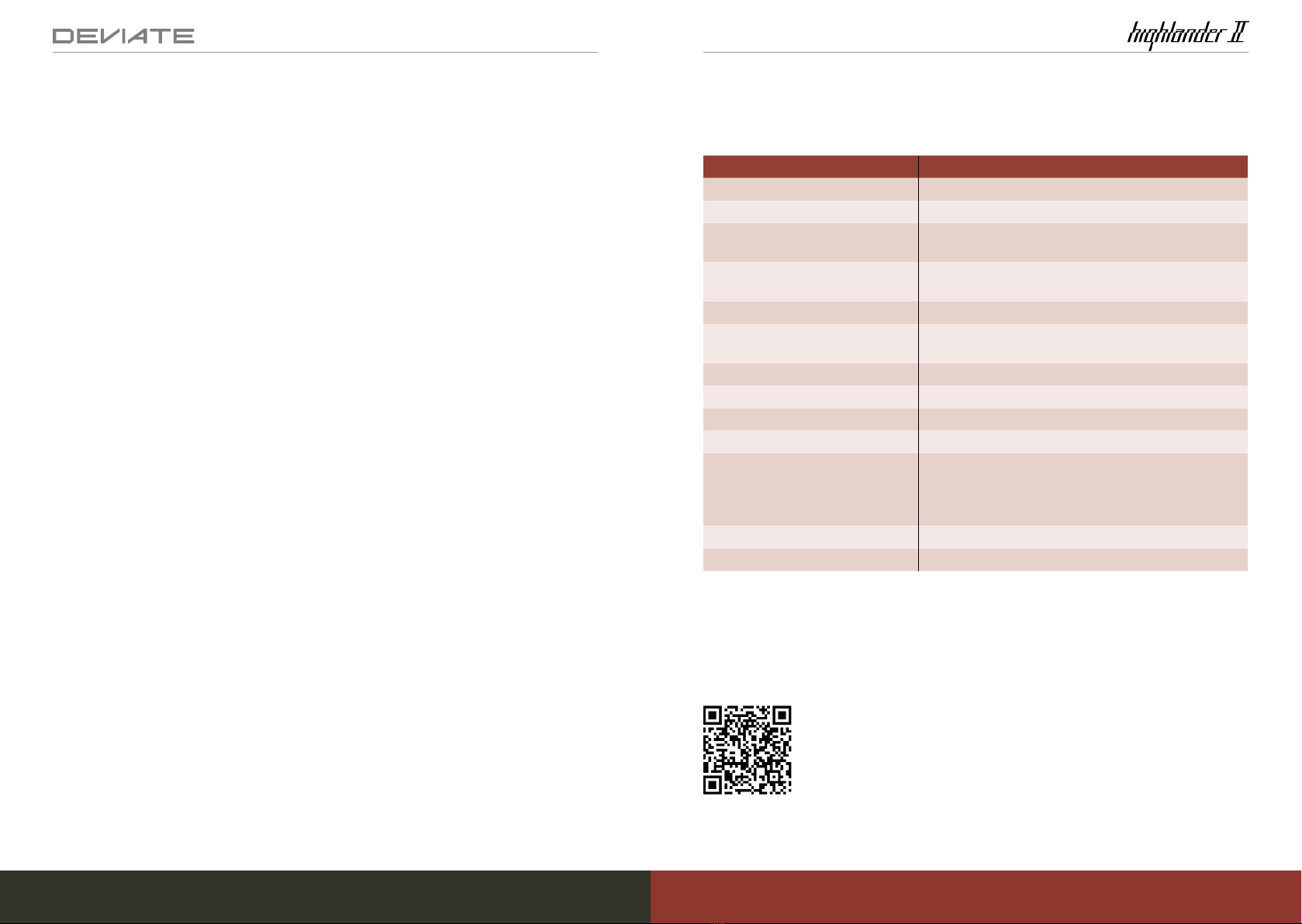

PARTS LIST

QUICK REFERENCE SPARES

The following table is a quick reference for typical spares you might need over the life of the bike:

Part Part Number Quantity Per Frame

Dropout TRP04-D9-008-C 1

Rear Axle TRP04-S9-022-A 1

Idler TRP04-D9-006-D 1

Idler Bearings 61803_2RS1 2

Main Pivot, Rear Links, Extender Bearing 3802 LLU MAX 7

Rocker Bearing 6808 LLU MAX 2

Idler Seals, Main Pivot Seals SEAL - 20x26x4 VC 10

Rear Triangle Inner Seal SEAL - 16x22x4 VC 2

Cable Grommet (Large) G10 RCS60-00-45 2

Cable Grommet (Small) G10 RCS50-00-35 3

Deviate Cycles can happily supply any spares

that you may need for your bike, but some

items such as bearings and seals can be

sourced from you local bearing dealer.

For all other frame related spares please

contact us or check the online store. The use

of non-genuine parts is not recommended

and would void the warranty associated with

Deviate products.

BOLT TORQUE SUMMARY

Part Torque (Nm)

Main Pivot Bolt 30

Pull Link to Rocker Bolt 30

Pull Link to Rear Triangle Bolt 20

Shock Extender to Rocker Bolt 20

Sleeve - Shock 20

Sleeve - Frame Bolt 10

Rear Axle 10

Idler Cover Bolts 2

Drop Out Bolts 2

Bottle Cage Bolts 3

If a bolt is found to

be loose it should be

removed and the relevant

thread locktite should be

applied as detailed in

the product diagrams on

pages 8, 10, 12.

98

Deviate Highlander II User Manual v1.2 12.12.23Deviate Highlander II User Manual v1.2 12.12.23

FRONT TRIANGLE ASSEMBLY - DIAGRAM

View page 9 to see the corresponding parts table.

Loctite 243

Loctite 638

Grease

Align flats

during assembly

Cross section on Main Pivot bearings

12

FRONT TRIANGLE ASSEMBLY - PARTS TABLE

View page 8to see the corresponding diagram.

Item Part Number Name Notes QTY

1 TRP08-F9-XXX Frame - Carbon 1

2TRP04-F9-010-B Clamp - Cable Gutter 4

3TRP04-F9-011-B Top Hat - Pivot 4

4TRP04-S9-035-C Spacer Tube - Main Pivot 1

5AMP06-F9-013-A Sleeve - Frame Bolt 1

6TRP04-F9-017-A Bolt - Sleeve Frame 1

7TRP04-F9-015-C Axle - Bottom Bracket 1

83802LLUMAX Enduro Bearing 2

9BTN_HEAD_M5x18 BUTTON HEAD - M5x18

- SS A2/A4

Torque to 4.5 Nm 4

10 WASHER_

DIN988_8x14x0.5

Washer - DIN988 8x14x0.5 2

11 SEAL_20x26x4_VC SEAL - 20x26x4 VC - NITRILE Apply grease to lips 2

12 O-RING_15x1_5 O-RING - 15x1.5mm - NITRILE Prepare with grease 2

13 / / Not shown /

14 TRP04-F9-024 Washer - BB Replaces 2.5mm

spacer with BB

1

15 TRP08-F9-007-A Protection - Downtube 1

16 G10_RCS50-00-35 Grommet (Small) 1

17 CL-FJ21-1 Deviate Seat Clamp Apply grease prior to

seat post installation

1

18 WAFER_HEAD_

M6x16

WAFER HEAD M6x16 2

1110

Deviate Highlander II User Manual v1.2 12.12.23Deviate Highlander II User Manual v1.2 12.12.23

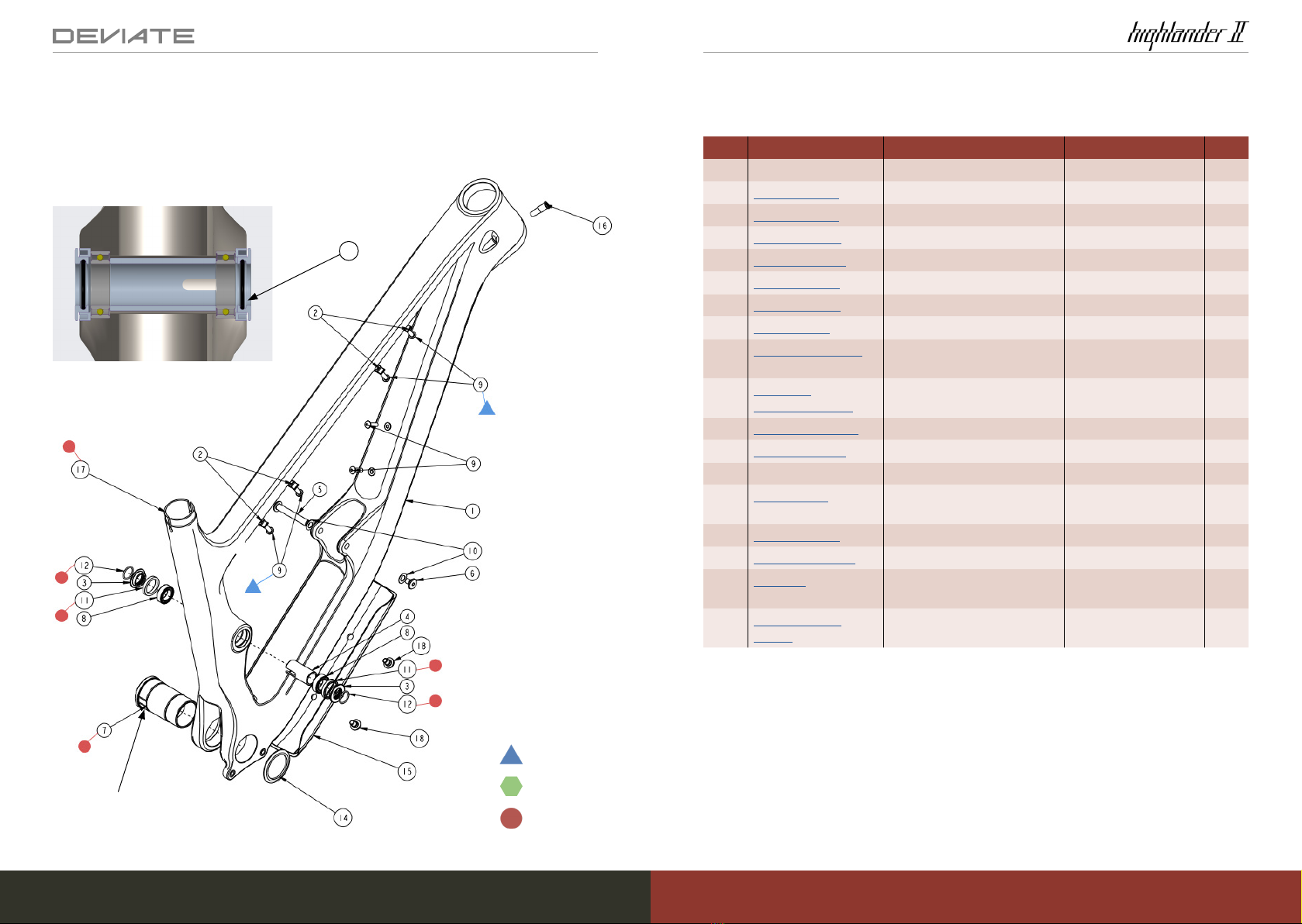

REAR TRIANGLE ASSEMBLY - DIAGRAM

View page 11 to see the corresponding parts table.

Cross section on

link bearings

Loctite 243

Loctite 638

Grease

Grease Port

REAR TRIANGLE ASSEMBLY - PARTS TABLE

View page 10 to see the corresponding diagram.

Item Part Number Name Notes QTY

1 TRP08-S9-XXX Rear Swing Arm 1

2TRP04-S9-029-F Axle - Main Pivot Loctite Threads w/243 1

3TRP04-D9-007-J 52mm Idler Cover 55mm Idler Cover =

AMP06-D9-011-A

1

4 TRP04-S9-063-B Chain stay protector 1

5TRP04-D9-008-C Drop Out - 12x148 UDH Hanger =

411H0300001

1

6TRP04-D9-009-B Insert - Rear Axle 1

7TRP04-S9-022-A Rear Axle 148x12 UDH Axle =

411L12B2000003

1

8AMP06-F9-020 Top Hat - Pivot Small Fit o-ring 12x1.5 w/grease 2

9TRP04-D9-006-D 52mm Idler - 18T 55mm Idler = AMP06-D9-

012-B

1

10 61803_2RS1 BEARING - 61803 2RS 2

11 3802LLUMAX ENDURO BEARING 3802

LLU MAX

2

12 SEAL_20x26x4_VC SEAL - 20x26x4 VC

- NITRILE

Prepare with grease 4

13 SEAL_16x22x4_VC SEAL - 16x22x4 VC

- NITRILE

2

14 O-RING_12x1_5 O-RING - 12x1.5MM

- NITRILE

Replaces 2.5mm spacer

with BB

2

15 CAP_M4x16 CAP HEAD - M4x18

- SS A2/A4

Torque to 2 Nm 1

16 CAP_M5x16 CAP HEAD - M5x16

- SS A2/A4

Loctite 243, Torque 2Nm 3

17 WASHER_

DIN988_15x21x1

WASHER - DIN988

- 15x21x1 - SS

1

18 GRUB_SCREW-M5x5 GRUB SCREW - M5x5

- SS A2/A4

Loctite Threads w/243 1

19 ZERKS_FITTING 10-32 UNF Flush Straight

Slotted

Loctite Threads w/638 2

20 G10_RCS50-00-35 Grommet (Large) 2

21 G10_RCS60-00-45 Grommet (Small) 2

1312

Deviate Highlander II User Manual v1.2 12.12.23Deviate Highlander II User Manual v1.2 12.12.23

ROCKER - DIAGRAM

View page 13 to see the corresponding parts table.

Loctite 243

Loctite 638

Grease

Grease Port

ROCKER - PARTS TABLE

View page 12 to see the corresponding diagram.

Item Part Number Name Notes QTY

1TRP08-S9-002 Rocker - 145mm 1

2TRP08-S9-004 Link - 145mm 1

3TRP04-F9-011-B Top Hat - Pivot 4

4TRP04-F9-013-B Top Hat - BB 2

5TRP04-S9-045-D Axle Bolt - Swingarm Link Tighten to 20Nm 2

6TRP04-S9-030-F Axle - Swing Arm Link Tighten to 30Nm 1

7TRP04-S9-036-C Spacer Tube - BB 1

8TRP04-S9-037-C Spacer Tube Rocker 1

9TRP08-S9-003 Shock Extender - 145mm 1

10 TRP04-S9-046-A Sleeve - Extender Tighten to 12Nm 1

11 TRP04-S9-049-B Sleeve - Shock Fitted for transport 1

12 6808LLUMAX Enduro Bearing 6808 LLU MAX 2

13 3802LLUMAX Enduro Bearing 3802 LLU MAX 3

14 SEAL_20x26x4_ Seal - 20x26x4 VC Apply grease to lips 4

15 SEAL_45x52x4_ Seal - 45x52x4 VC Apply grease to lips 2

16 O-RING_15x1.5 O-RING - 15x1.5MM - NITRILE Prepare w/grease 4

17 O-RING_40x1.5 O-RING - 40x1.5MM - NITRILE Prepare w/grease 2

18 WASHER_

DIN988_15x21x1

WASHER - DIN988 - 15x21x1 -SS 1

19 ZERKS FITTING 10-32 UNF Flush Straight Slotted 6

20 GRUB_M5X5 GRUB SCREW - M5x5 - SS A2/A4 4

1514

Deviate Highlander II User Manual v1.2 12.12.23Deviate Highlander II User Manual v1.2 12.12.23

WARRANTY

All of Deviate Cycles frames come with a lifetime warranty. This warranty comes with some

important conditions.

We want you to have peace of mind when purchasing a Deviate. We produce high end

carbon frames and stand behind our product 100% with a lifetime warranty. Saying that, in

return we expect you to maintain your frame and not use it beyond it’s intended limits.

If our analysis (or your honesty) suggests abnormal loading, for example due to casing

downhill style jumps on a trail bike - then our crash damage replacement policy will apply.

Our engineering team have extensive experience with carbon fibre failure analysis so their

decision is final.

The following conditions apply to the lifetime

warranty:

• Lifetime Warranty is only valid for

manufacturing defects.

• Applies to frame-set and machined parts.

• Valid for intended and appropriate

use only.

• Warranty only applies to the original owner

with proof of purchase.

• Does not include any work associated with

warranty process (i.e. stripping down or

re-building a replaced frame).

• Does not include import tax or duty when

shipping outside the UK.

• If a replacement in required we will

endeavour to replace like for like - but

if this is not possible we may offer an

alternative.

• Subject to exclusions (see page 14).

WARRANTY EXCLUSIONS

• Wear and tear.

• Paintwork. 2 year warranty applies to

paintwork manufacturing defects. Custom

painting voids the frame warranty except

where carried out by an authorised paint-

shop or where written authorisation is

obtained from us. Where an authorised

paint-shop is used, we take no liability for

this work and will be not liable for any

costs incurred due to a separate warranty

claim, for example where re-painting may

be required due to a replacement part.

• Where clear protection is applied, this

voids any warranty we supply on the

paintwork including any damage to the

existing paint occurring during removal or

fitting.

• Cable rub and other friction damage.

• Bearings and other “wear parts” i.e. the

idler wheel and seals.

• Damage occurring due to insufficient

maintenance or poor treatment. Refer to

the manual for maintenance instructions.

• The fitment of incompatible parts voids

the warranty. For the avoidance of doubt,

forks beyond the travel range quoted for

a frame are deemed incompatible, as are

wheel sized that are not quoted for the

frame or 3rd party linkages.

• Damage occurring due to the seizing of

bolts or components due to insufficient

maintenance or over-tightening. To be

clear if lack of maintenance causes the

linkage or bearings to seize and this

results in damage to the frame, this is not

covered.

• Damage occurring as a result of over-

torquing, cross threading or other mis-

fitting of components. Refer to manual for

tightening torques.

• Damage occurring due to impact damage

of any description.

• Damage occurring where another vehicle

or bicycle is involved.

• Damage occurring due to extreme

temperature exposure (cold night rides

okay, liquid nitrogen not okay | hot

deserts okay, blowtorch not okay).

• Any component not manufactured by

Deviate Cycles (i.e. rear shock and other

build parts). Refer to relevant manufacture

for warranty details.

• Crash damage (see crash replacement

policy) and other damage caused by the

environment (i.e. rock strikes).

• Beyond intended/appropriate use. i.e.

using a trail bike for downhill riding.

• Professional competitive use.

• Deliberate damage including attempted

theft.

• Damage that occurs during transit

(i.e. by an airline or in a vehicle).

FUNCTIONING OF WARRANTY

It is our decision if either the bike must be

returned to us for inspection or photos must

be provided. The frame must be stripped of

all non warranty components and cleaned.

You will be charged for the pick up service

and if the warranty is confirmed the shipping

cost will be refunded in full. If the warranty

case is declined then you will be charged

for return shipping, if required.

Our decision is final on warranty matters.

Your statutory rights are not affected.

For questions or warranty claims please

email [email protected]

16

Deviate Highlander II User Manual v1.2 12.12.23

Deviate Cycles Limited,

Main Street, Kinbuck, Dunblane, FK15 0NQ

tel. +44 (0) 1786 643486

email. info@deviatecycles.com

web. deviatecycles.com

Deviate Highlander II User Manual v1.2 12.12.23

Table of contents

Other DEVIATE Bicycle manuals