aerosolv 6000 User manual

aerosolv

®6000

AEROSOL CAN RECYCLING

A

E

R

O

S

O

L

V

AEROSOLV.COM

MODEL 6000

TABLE OF CONTENTS

6000 INSTRUCTION MANUAL

2 Introduction to the Aerosolv® 6000 Recycling System

3 Safety Instructions

4 Aerosolv 6000 Unit Installation

5 Aerosol Can Puncturing Using the Aerosolv 6000 System

5 Aerosolv 6000 Filter

8 Aerosolv 6000 Maintenance

10 Mile Marker Chart & Drum Capacity Determination

11 Table 1-1: Sample Aerosol Can Segregation Scheme

12 Table 1-2: Recommended Aerosol Product Consolidation

Scheme

14 Table 1-3: Aerosol Consolidation Classes

15 Table 1-4: Aerosol Class Compatibility Chart

15 Table 1-5: Aerosol Class Consolidation Chart

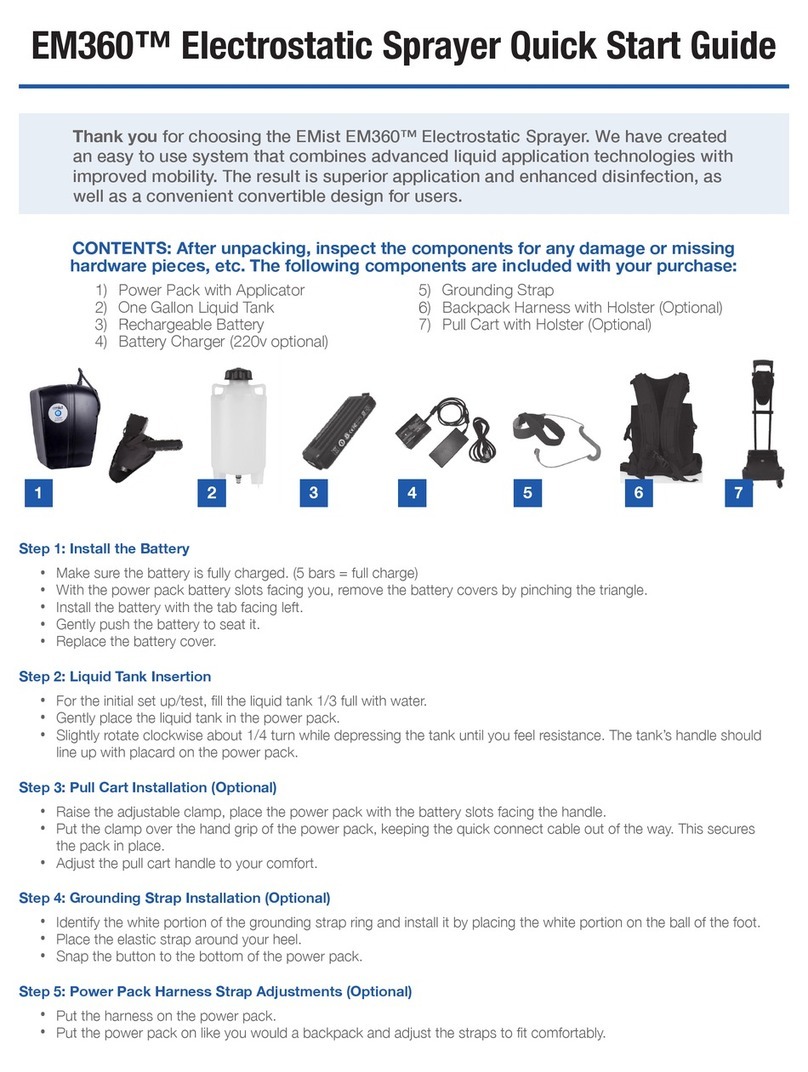

The Aerosolv 6000 Aerosol Can Recycling System simplifies

aerosol can disposal, safely and eciently. The puncturing unit

threads directly to the 2” bung of any 30-gallon or 55-gallon drum.

Simply insert an inverted aerosol can into the Aerosolv® unit and

lock the sliding top plate. With a press of the handle, a specially

designed puncture pin pierces the dome of the can. The contents

are dispersed down and directly into the receiving drum; the partic-

ulate laden propellant is coalesced in the first stage of the Aerosolv

3601 high eciency combination filter providing propellant flow to

the carbon cartridge. What’s left is an aerosol can that is fully recy-

clable; eliminating an entire waste stream.

The result? Recyclable scrap steel.

After processing aerosol cans with the Aerosolv system, you’ve got

an empty steel can with a small, smooth-edged hole. No spills. No

jagged edges. And, no compressed gas, so it’s ready for recycling

with other scrap steel.

INTRODUCTION TO THE AEROSOLV 6000

AEROSOL CAN RECYCLING SYSTEM

SAFETY INSTRUCTIONS

1. Wear safety goggles while operating the Aerosolv® system.

2. DO NOT use Aerosolv while smoking or near open flame.

3. Install anti-static wire to properly “ground” drum.

4. DO NOT use Aerosolv on a drum with less than 30-gallon

capacity.

5. Remove Aerosolv to an empty drum once collection drum is 70%

full (when contents reach within 10” of the top).

6. Always engage sliding top plate and sealing knob against can

being punctured.

7. Always operate the Aerosolv system outdoors or in a well

ventilated area. Propellant is heavier than air and may collect at

point of generation.

8. Do not use the Aerosolv unit for pesticides, herbicides,

adhesives, or corrosive materials with pHs less than 2.0 or greater

than 12.5 (i.e., Easy-O®, corrosive acidic, and alkaline products).

Comingling incompatible can contents can be hazardous. Operator

must develop a segregation scheme to ensure safe operation and

liquid collection.

9. Process like aerosol cans to the same collection drum for

recycling (e.g., paints with paints, cleaners & degreasers with same)

10. Tip: Avoid puncturing aerosol cans of cold galvanizing

compound or insulation foam, unless can is empty.

.

Thread the aluminum filter base with the attached

activated carbon filter carbon filter into the 3/4” bung

of the liquid collection drum - your system setup is now

complete.

AEROSOLV 6000 UNIT INSTALLATION

Obtain a 30 or 55-gallon liquid collection drum, poly or

steel, possessing two standard bungholes: one large 2”

bung; and one small 3/4” bung. Select a receptacle that

is compatible with the aerosol product to be captured

and inspect the receptacle for deterioration or signs of

breached integrity. Ensure the bung caps for each hole

are in place. Remove the bung caps and store them in a

safe place so that they may be used later.

Thread the Aerosolv® unit into the 2” bung. Rotate

clockwise until ground support plate firmly engages

drum rim.

Attach ring terminal of anti-

static wire to the brass screw on

Aerosolv ground support plate.

See inset. Secure alligator clip

to any nearby confirmed ground

source. Electrical grounding must

comply with the applicable state

and federal regulations.

USING THE AEROSOLV® 6000 SYSTEM

AEROSOLV 6000 FILTER

• Wear safety goggles while operating Aerosolv

• Insert aerosol can, NOZZLE END DOWN, into Aerosolv housing

sleeve, so that shoulder of can rests on gasket. Be sure to remove

cap from aerosol can prior to insertion.

• When puncturing oversized “jumbo” cans, remove white poly

sleeve from Aerosolv housing, then insert can as above.

• Lower sliding top plate and FIRMLY engage the cap compression

knob against bottom of can. Twist cap copression knob to adjust.

TIGHTEN lock knob on slide bar.

• Push handle down firmly until completely

depressed and hold in place while can

releases initial pressure. See inset. Slowly

raise the handle and immediately depress,

this will control the rate of pressure and

content evacuation from the aerosol can.

In order to prevent back pressure, allow

the contents of the can to drain into the

collection drum (about 20 seconds).

Tip: Prevent vapors from escaping through 2” bung opening by

leaving the last can punctured in the puncturing device.

When venting an aerosol can the activated carbon will generate

heat as the granular carbon adsorbs the hydrocarbons. Typically

20-25 degrees above ambient temperature. This will activate

the liquid crystal indicator to signal adsorption of VOC’s and will

light ‘RED’ during the adsorption process. Returning to black

when the adsorption process is complete.

ADSORPTION INDICATOR

Remove the weather cap and

place on drum. There is no need

to remove the upper filter housing

from the lower filter housing

during this process. See Figure 1.

Remove the activated carbon

filter insert. See Figure 2. Set the

used filter aside to be disposed

of in accordance to local, state,

and federal laws. Check with local

authorities having jursidiction.

FILTER MAINTENANCE

• Replace the activated carbon filter

insert (inside upper portion) and the

coalesceing filter with pull tab (inside

lower housing) every 1000 cans or

when the adsorption indicator no

longer appears ‘RED’ when venting

aerosol cans. More frequent change-outs may be necessary based

on use and volume of the cans processed. (Aerosol cans with 25%

or less content may not activate indicator.)

• To replace simply order Part #3602 – Filter Replacement Kit, which

includes 2 internal coalescers and 2 activated carbon filter inserts.

See Mile Marker Chart for maintenance schedule.

HOW TO CHANGE OUT YOUR

FILTER COMPONENTS

Pull Tab

Remove the internal coalescer

using the pull tab from the

aluminum base. See Figure 3.

Visually inspect the base for any

standing liquids. If liquid has

collected in the base drain the

contents following the instructions

provided on the green lower filter

housing label.

Reassemble your filter starting with

the internal coalescer making sure

you get a snug fit in the aluminum

base. See Figure 4. Insert a new

activated carbon filter, make sure

you remove it from the shrink wrap

and align the sight window with the

adsorption indictor. See Figure 5.

Finally, twist your weather cap back

into place. See Figure 6.

•To restock order Part #3602 – Filter Replacement Kit

• Periodically check and empty the collected liquid content in the filter

base if needed. To empty, remove the carbon filter housing from the

aluminum filter base.

• Unscrew the filter base from the drum and carefully drain the collected

liquids through the AEROSOLV housing directly into the drum.

MAINTENANCE

AEROSOLV ANTI-STATIC WIRE

AEROSOLV MAINTENANCE

COMPLIANCE

OSHA requires that liquid storage vessels be

grounded to prevent static electricity build-up.

The Aerosolv System includes an anti-static

wire for user convenience.

By bringing the propellant to atmospheric pressure, Aerosolv

achieves compliance with:

› 40 CFR 261.7(b)(1)

› 40 CFR 261.7(b)(1)(B)(2)

› 40 CFR 261.23(a)(6)

Periodic cleaning and greasing of the puncture pin will assure years

of use. With constant, heavy usage, the puncture pin should be

cleaned and greased once a month.

• To clean or replace puncture pin, remove bridge pin at

uppermost point of handle. Entire handle mechanism and

puncture pin can be removed.

Gasket deterioration will occur when venting aerosol paints and

aggressive solvents, requiring periodic gasket replacement. To

assure proper seal during Aerosolv usage, check gaskets frequently

and replace as required.

• To replace gasket, remove white plastic sleeve from Aerosolv

housing, then simply pull out old gasket and snap in replacement.

REPLACEMENT ACCESORIES FOR #6000

#6000 AEROSOLV CAN RECYCLING SYSTEM

RECYCLING

Once relieved of pressure, aerosol cans are not regulated waste

(OSWER Directive 9432.01 (80)). In addition, puncturing aerosol cans

to achieve atmospheric pressure is not considered “treatment”;

therefore, permitting is not required.

• Recycling 8,000 aerosol cans reduces solid waste and

increases recycling by one ton.

• By installing Aerosolv® systems on two drums, non-chlorinated

aerosols can be collected separately, then reclaimed as

solvents, resulting in waste minimization credits.

• Cans punctured using Aerosolv may be recycled with other

scrap steel.

Aerosolv leaves only a smooth edged hole.

• Puncturing unit with built in

safety shield slide bar

• Anti-static wire

• Safety goggles

• #3601 High eciency

combination carbon filter

with extreme duty aluminum

filter base

Maintenance repair kit: includes puncture pin with o-rings,

aeroprene gasket, bridge pins, spring and tube of grease

Replacement carbon cartridge for combination filter with flashback

inhibitor (pkg of 2), high eciency proprietary polymer coalescer (pkg of 2)

Aeroprene gasket

Model #3602

Model #5165EX

Model #5129

MILE MARKER CHART

DRUM CAPACITY DETERMINATION

1000

2000

3000

4000

4500

Replace Activated Carbon Cartridge and internal coalescer

Replace Activated Carbon Cartridge and internal coalescer —

check aluminum filter base for collected liquids

Replace Activated Carbon Cartridge and internal coalescer —

check aluminum filter base for collected liquids

At this point a 55 gallon drum should be 75–80% full and

ready for handling. Reset the counter. Mount the Aerosolv

6000 system and new combination filter onto an empty

drum. Depending on wear, replace housing o-ring, clean out

the system including the filter base, reapply PTFE tape to the

threads, and lubricate the rack gear.

Replace Activated Carbon Cartridge and internal coalescer

CAN COUNT ROUTINE MAINTENANCE & FILTER CHANGES

The volume of liquid accumulating in the liquid collection drum should be

noted prior to commencing operations. Procedures for determining when

the collection receptacle is full are as follows:

1. Using the drum level indicator provided with your system follow steps 2 through 6.

2. Remove the weather cap and place on drum. There is no need to remove the upper filter

housing from the lower filter housing during this process.

3. Remove the activated carbon filter insert as well as the internal coalescer using the pull

tab from the aluminum base.

4. Carefully drop the drum level indicator into the filter hosing through the hole that is now

visible allowing disc to rest on the filter housing.

5. Slowly raise the tool and inspect it to determine whether liquid has reach the end of

the rod.

6. If the liquid level in the collection container actually reached the end of the rod when

submerged, secure the container, wipe o the tool using the rag, and call for pick

up. If the liquid level has not yet reached the ruler, continue to puncture aerosol cans

in accordance with the Aerosolv 6000 manufacturer’s operation and maintenance

instructions. Repeat steps 2 through 6 to check the liquid level every 500 cans.

AEROSOL TYPES COMMON EXAMPLES

1- Ignitable solvent product w/flammable

propellant

Prestone® Starting Fluid, Keen Limited® Zeus®

Butane, Malter® Dimethylsilicone Lubricant

Compound, Liquid Wrench®, WD-407

2- Hydrocarbon product w/flammable

propellant

OMC® Anticorrosion Spray, Sprayon® Gear Lube,

Panef® Lubricant with Teflon®, Zep® Cutting Oil,

Solid Film Lubricant, Penetrating Fluid

3- Halocarbon product w/flammable

propellant

Freon 114, Degreaser

4- Halocarbon product w/nonflammable

propellanti

Dichlorotetrafluoroethane, Freon 113, Berryman®

Brake Cleaner

5- Hydrocarbon product w/ nonflammable

propellant

Nut Buster® Penetrating Oil, Corrosion Preventative

Compound, General Purpose Lubricating Oil

6- Toxic constituent containing product w/

flammable propellant

Enforcer® Wasp and Hornet Killer, D-trans Allethrin

7- Toxic constituent containing product w/

nonflammable propellant

PT 270 Dursban®, PT 515 Wasp Freeze®, PT-240

Perma Dust®, PT-279 Engage7

8- Corrosive product with flammable

propellant: 8A: Acidic Product

8B: Alkaline Producti

Easy O® Oven Cleaner, Degreaser

9- Corrosive product with nonflammable

propellant: 9A: Acidic Product

9B: Alkaline Product

Oven Cleaner, Degreaser

10- Non-toxic product with flammable

propellant

Lemon Pledge®, Glade® Air Freshener, Pam®

Coating

11- Listed product with flammable

propellant

Block Cleaner, Hi-Tech Safety Solvent® 1,1,1-

trichloroethane, Sprayon® 1,1,1- trichloroethane

12- Listed product with nonflammable

propellant

Bulk Chemical® 1,1,1-trichloroethane technical, Plaze

Inc.® 1,1,1-trichloroethane technical

13- Paints with flammable propellants Krylon®, Pittsburgh®

14- Adhesives with flammable propellants Super 7® Adhesive Spray®,

99MA High Tack Spray-AGasket 800657

TABLE 1-1

SAMPLE AEROSOL CAN SEGRAGATION SCHEME

CONSOLIDATION

FAMILY

AEROSOL TYPES

INCLUDED IN FAMILY

RATIONALE FOR

CONSOLIDATING TYPES

1- POL: Petroleum, Oil,

and Lubricants

(2) Hydrocarbon product/

flammable propellant

(15) Hydrocarbon product/

nonflammable propellant

Recovered POL can be recycled and used for

fuel blending. Propellants captured from POL

aerosol cans are adsorbed on the activated

carbon filter. Saturated activated carbon

cartridges are properly disposed of as nonreg-

ulated refuse.

2- Paints (13) Compatible paints Paints are recovered and stored in appropriate

containers. Recovered paints are managed

as hazardous wastes and either recycled or

transferred to an appropriate treatment facility.

Propellants captured from paint aerosol cans

are adsorbed on the activated carbon filter.

Saturated activated carbon cartridges are

properly disposed of as non-regulated refuse.

3- Adhesives (14) Compatible adhesives Adhesives are recovered and stored in

compliant containers. Recovered adhesives

are managed as hazardous waste and either

recycled or transferred to an appropriate

treatment facility. Propellants captured from

adhesive aerosol cans are adsorbed on the

activated carbon filter. Saturated activated

carbon cartridges are properly disposed of as

non-regulated refuse.

4- Compatible Alka-

line Cleaners

(8B) Corrosive product/

flammable propellant

(9B) Corrosive product/

nonflammable propellant

If compatible, aqueous alkaline products from

aerosol cans are recovered and consolidated

with similar products. These materials can be

transferred to an appropriate treatment facility.

Propellants captured from these aerosol cans

are adsorbed on the activated carbon filter.

Saturated activated carbon cartridges are

properly disposed of as nonregulated refuse.

5- Compatible Acidic

Cleaners

(8A) Corrosive product/

flammable propellant

(9A) Corrosive product/

nonflammable propellant

If compatible, aqueous acidic products from

aerosol cans are recovered and consolidated

with similar products. These materials can be

transferred to an appropriate treatment facility.

Propellants captured from these aerosol cans

are adsorbed on the activated carbon filter.

Saturated activated carbon cartridges are

properly disposed of as nonregulated refuse.

TABLE 1-2

RECOMMENDED AEROSOL PRODUCT

CONSOLIDATION SCHEME

CONSOLIDATION

FAMILY

AEROSOL TYPES

INCLUDED IN FAMILY

RATIONALE FOR

CONSOLIDATING TYPES

6- Halocarbon

Solvent

(3) Halocarbon product/

flammable propellant

(4) Halocarbon product/

nonflammable propellant

Recovered halocarbon solvents may be

distilled and reutilized or transferred to an

appropriate treatment facility. Propellants

captured from halocarbon aerosol cans

are adsorbed on the activated carbon filter.

Saturated activated carbon cartridges

areproperly disposed of as non-regulated

refuse.

7- Ignitable Solvents (1) Ignitable solvent product/

flammable propellant

Recovered ignitable solvents may be

distilled and reutilized, recycled as fuel, or

transferred to an appropriate treatment facility.

Propellants captured from these aerosol cans

are adsorbed on the activated carbon filter.

Saturated activated carbon cartridges are

properly disposed of as non-regulated refuse.

8- Listed Products 11) Listed product/

flammable propellant

(12) Listed product/

nonflammable propellant

Listed products may be distilled and reutilized,

recycled, or collected in isolated vessels

and managed as listed hazardous wastes.

Propellants captured from these aerosol cans

are adsorbed on the activatedcarbon filter.

Saturated activated carboncartridges are

properly disposed of as non-regulated refuse.

9- Toxic Products (6) Toxic product/

flammable propellant

(7) Toxic product/

nonflammable propellant

Toxic products are either recycled or managed

as hazardous waste and transferred to an

appropriate treatment facility. Propellants

captured from these aerosol cans are

adsorbed on the activated carbon filter.

Saturated activated carbon cartridges are

properly disposed of as non-regulated refuse.

10- Non-Toxic

Products

(10) Non-toxic product/

flammable propellant

Non-toxic products are managed appropriately.

Propellants captured from these aerosol cans

are adsorbed on the activated carbon filter.

Saturated activated carbon cartridges are

properly disposed of as non-regulated refuse.

TABLE 1-2 (CONT’D)

RECOMMENDED AEROSOL PRODUCT

CONSOLIDATION SCHEME

CONSOLIDATION

FAMILY

AEROSOL TYPES

INCLUDED IN FAMILY

RATIONALE FOR

CONSOLIDATING TYPES

1- Petroleum

Hydrocarbons (non-

halogenated)

(1) POL

(2) Paints1

(7) Ignitable Solvents

(8) Listed Products2

(9) Toxic Products3

(10) Non-Toxic Products3

See Footnotes 1, 2, and 3

2- Resinous Materials (3) Adhesives Adhesives and other resinous coagulating

materials tend to diminish the quality of

otherwise recyclable solvent products. Further,

these products accelerate the deterioration of

process equipment.

3- Aqueous Liquids (4) Alkaline Cleaners4

(5) Acidic Products4

(9) Toxic Products5

(10) Non-Toxic Products5

See Footnotes 4 and 5

4- Halocarbon

Solvents

(6) Halocarbon Solvents Many petroleum products cannot be recycled

when contaminated with halocarbons. Though,

halocarbon solvents are compatible with

and can typically be commingled with other

petroleum products and solvents.

5- Alkaline Products (4) Corrosive Alkaline Products Alkaline products potentially

present a threat of heat generation through

acid-base or oxidation-reduction reactions.

1 Paints may either be consolidated separately or consolidated with other petroleum and petroleum-based products.

If the resulting waste is going to be incinerated or fuel blended (provided the paint solids do not compromise the

quality of the mixture), the paints may be consolidated with other products. If the resulting waste is to be recycled or

otherwise utilized, the paint should be managed independently.

2Listed petroleum and petroleum-based wastes may be commingled with other petroleum products if the resulting

mixture is characterized in accordance with the Mixture and Derived from Rules (40 CFR, ‘261.3), and if the mixture

will be either incinerated or fuel blended. Listed wastes may not be commingled with other wastes if the resulting

mixture is not characterized and managed as a listed hazardous waste.

3Toxic and non-toxic petroleum products may be commingled with other petroleum products unless the resulting

mixture is intended for specific recycling or reuse eorts and the addition of these products significantly diminishes

the quality of the final product. Non-petroleum products may not be commingled with petroleum products.

4Aqueous acidic and alkaline products whose pH remains between 4.0 and 10.0 may be commingled as long as the

constituents that comprise the solutions are compatible. Products exhibiting pHs significantly greater than 10.0 or less

than 4.0 should not be commingled. Additionally, non-aqueous solutions should not be commingled with aqueous

solutions.

5Aqueous toxic and non-toxic products may be commingled with other aqueous wastes provided the constituents that

comprise the products are compatible with each other. The characterization of the resulting mixture must be similar to

that of the products prior to introduction.

TABLE 1-3

AEROSOL CONSOLIDATION CLASSES

petroleum

hydrocarbons

resinous

materials

aqueous

liquids

halocarbon

solvents

alkaline

products

acidic

product

petroleum hydrocarbons yes yes6yes7yes6no8no8

resinous materials yes6yes no9yes no no

aqueous liquids yes7no9yes yes10 yes yes

halocarbon solvents yes6yes yes10 yes no11 no11

alkaline products no8no yes no11 yes no

acidic product no8no yes no11 no yes

petroleum

hydrocarbons

resinous

materials

aqueous

liquids

halocarbon

solvents

alkaline

products

acidic

product

petroleum hydrocarbons yes no no no no no

resinous materials no yes no no no no

aqueous liquids no no yes no no no

halocarbon solvents no no no yes no no

alkaline products no no no no yes no

acidic product no no no no no yes

6 Refer to recommended consolidation chart.

7Petroleum hydrocarbons are compatible with but not typically soluble in aqueous liquids. Refer to recommended

consolidation chart.

8Petroleum hydrocarbons and corrosive materials are typically compatible. However, some corrosive matrials

are incompatible with petroleum hydrocarbons. As such, for purposes of simplicity, this chart recommends not

commingling the two.

9Some resinous materials react adversely with water. This chart reflects conservative management.

10 Halocarbons are compatible with but not typically soluble in aqueous liquids. Refer to recommended

consolidation chart.

11 Halocarbon solvents and corrosive materials are typically compatible. However, some corrosive materials are

incompatible with halocarbons. As such, for purposes of simplicity, this chart recommends not commingling the two.

TABLE 1-4

TABLE 1-5

AEROSOL CLASS COMPATIBILITY CHART

AEROSOL CLASS CONSOLIDATION CHART

MAINTENANCE LOG

DATE NAME MAINTENANCE PERFORMED

NOTES

RMP6001 Rev A ©2017 Aerosolv Incorporated. U.S. and other patents pending.

aerosolv.com

aerosolv AEROSOL

CAN RECYCLING

®

888-818-7114

RMP6001 RevB- ©2018 Aerosolv Incorporated US Patents: 9,845,232 and 9,827,528.

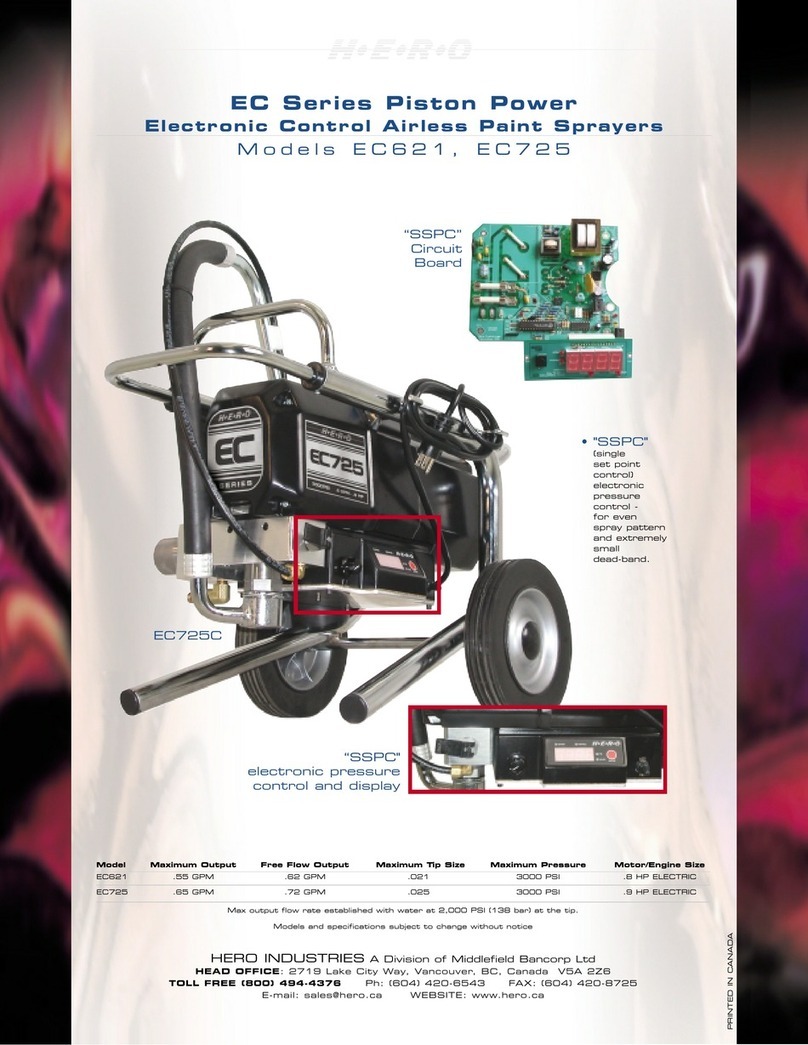

Popular Paint Sprayer manuals by other brands

Central Pneumatic

Central Pneumatic 47016 67181 Owner's manual & safety instructions

Garten Meister

Garten Meister GM AS 8 LI Original instructions

Glas Craft

Glas Craft LPA2-100G Operation manuals

U.S. General

U.S. General 95575 operating instructions

Stocker

Stocker 235 user manual

Titan

Titan IMPACT 1640 operating manual