How to use the S25 Sprayer

EarthWay’s S25 Spray-PRO sprayer is designed to be simple to use, easy on the operator and provide years of accurate spraying. The S25

is the latest development from EarthWay, world leaders in the manufacture of broadcast spreaders, seeding tools, and sprayers.

Calibration

The S25 is supplied with 3 different nozzle options. The table below shows the characteristics and performance of the supplied nozzle

options. You have the ability to adjust your spray width using the adjustable DCV holder which will also change the output volume per

square foot or meter.

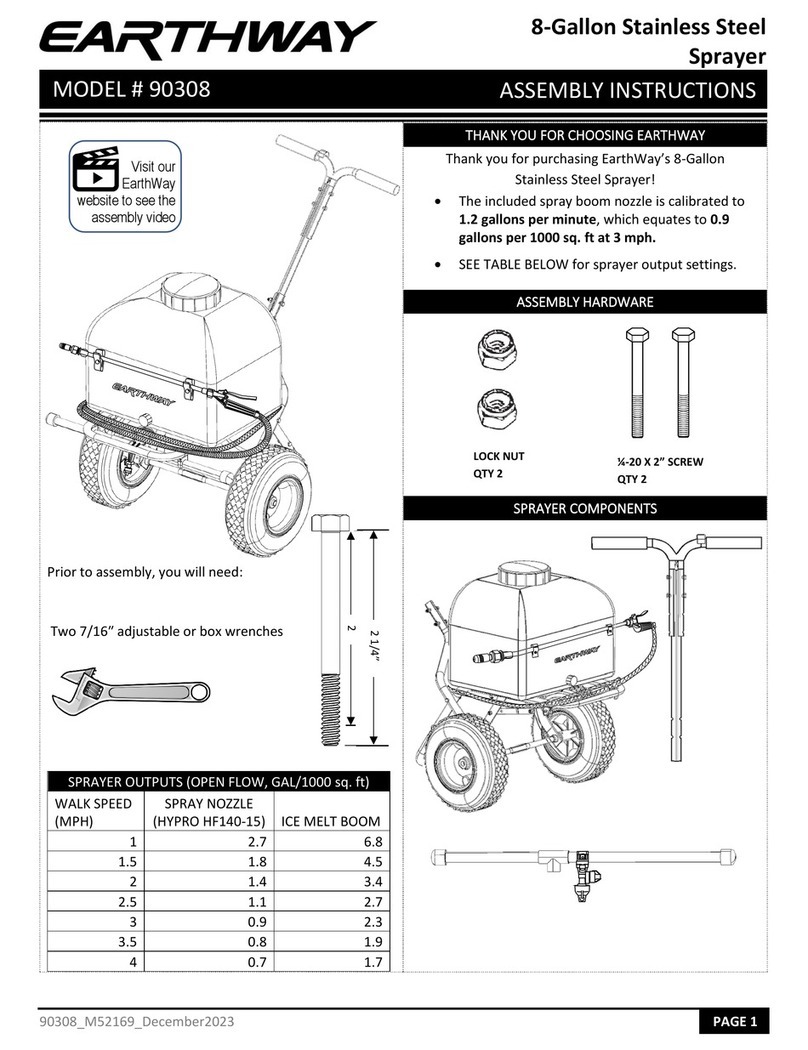

VOLUME COVERAGE BASED ON FULL TANK 6.6 GALLONS / 25 LITERS

Nozzle Square Feet Square Meters

Fluid OZ/Gal US

per 1,000 Square Feet

Fluid ML

per Square Meter

TF-VP4-5 11,400 1,059 74/.58 23.6

TF-VP4-7.5 7,280 676 116/.90 37

TF-VP4-10 7,040 654 120/.94 38.2

Before use

Before using any liquid products always read thoroughly the manufacturers product label, to ensure correct dosage and handling of the

product being applied through the applicator.

;Check that the applicator has been thoroughly cleaned from its previous use and that both the nozzle outlet and the handgun line have

been washed through.

;Always spray on a day where wind is minimal. It can be unsafe and inaccurate if spraying is undertaken in windy conditions.

;Always wear appropriate safety clothing when the sprayer is being used. Refer to manufacturers instructions, or contact your supplier

of the product being applied for safety recommendations.

;Make sure the tires are properly inated to 20 psi.

How to use ~ Walk behind spraying

Practice before use

It is recommended for rst time users of the machine that the user familiarizes him/her self with the workings of the sprayer. By simply

putting water in the spray tank and spraying it out onto a dry tarmac surface the operator will very quickly familiarize themselves with the

workings of the machine. Make sure the spray tank is then emptied of water before further use.

Make sure the handlebar is set right for the size of the operator. There are three position options on the upper handle for different user

heights. By having the handle in the correct position for the individual user it will make pushing the machine simpler and make spray

accuracy easier to achieve.

How to use

;Choose the correct nozzle of the 3 nozzle options that is suitable for the product being applied. (See calibration chart above)

;Ensure the Spray (on) / Transport (off) lever on the handlebar is in the Transport position. The Transport position is with the lever

over to the right side when standing behind the handlebars of the machine.

;Make sure the tank is clean and there is no chance of remnants or deposits from a previous spray task being left in the tank.

;With the tank clean ll the tank with the required volume of liquid for the designated spray task, making sure the product being used

is mixed and being applied in accordance with the manufacturers instructions.

;With the control lever is in the closed position as shown above the machine can be safely pushed to the area where spraying is to be

carried out.

;Locate the sprayer at the point at which spraying needs to commence. Lift the machine up off the two feet, so the body of the

machine is parallel with the ground (important see note (ii) on next page). To spray simply roll the On/Off lever over to the left side

(Spray position), and walk forward at a brisk walking speed 2 to 3 MPH is recommended.

;To stop the spray roll the on/off lever back to the right side position. Note. When the Spray/Transport lever is in the right side

(Transport position) and the machine is being pushed, the pump is pumping liquid out of the tank and circulating it back into the

tank. This circulation provides agitation and helps keep liquids that are mixed with water in suspension while walking the sprayer to

and from the area being treated.