Aerotec MKK-O-236 D User manual

ENGLISH - FRANÇAIS - ESPAÑOL - ITALIANO - NEDERLANDS - DEUTSCH -

SVENSKA - NORSK - DANSK - SUOMI - РУССКИЙ - POLSKI

Instruction manual

Mode d’emploi

Manual de instrucciones

Manuale istruzioni

Instructies gebruiksaanwijzing

Bedienungsanleitung

Instruktionshandbok

Bruksanvisning

Instruktionshåndbog

Käyttöopas

Руководство по эксплуатации

Instrukcja obsługi

ENGLISH

Instruction manual

3

1 - SAFETY PRECAUTIONS

1.1 Safety symbols

Explanation

Danger

Warning

Important note

1.2 General safety precautions

General precautions

1. The operator must adopt safe work procedures and comply with all the safety requisites and stan-

dards in the workplace.

2. Should any of the following provisions not conform to the regulations in force, the most stringent of

the two applies.

3. The activities relative to the installation, operation, maintenance and repairs must be carried out only

by suitably authorised, trained and specialised personnel.

4. The quality of the air generated by the compressor is not considered to be breathable. For the quality

of compressed air to be breathable, it must be suitably puried according to the applicable regula-

tions and standards.

5. Before carrying out any extraordinary maintenance, repair, adjustment or checking operations, stop

the compressor, press the emergency stop button, disconnect the mains and de-pressurise the com-

pressor. Furthermore, the isolating switch must be opened and properly locked.

6. Never play with compressed air. Do not aim it towards the skin nor aim air jets at persons.

Never use it to remove dirt from one’s own clothes. When compressed air is used to clean equipment,

handle it with extreme caution and wear protective goggles.

7. The owner is responsible for keeping the unit in safe operating conditions.All spares and accessories

that could in any way jeopardise safety must be replaced.

instruction manual

4

8. Do not walk or stand on the compressor or its components.

1.3 Safety precautions during installation

The manufacturer declines any responsibility whatsoever for damages or injuries

that may derive through failure in observing these precautions or normal caution

and through failing to provide the required attention for the installation, operation,

maintenance and repairs, even if not expressly quoted

Precautions during installation

1. The machine must be lifted by exclusively using suitable equipment, conforming to the applicable

safety regulations. Loose or rotating components must be safely secured before hoisting operations

are carried out. It is strictly forbidden to stop or stand in the risk area below suspended loads. Hoisting

acceleration or deceleration must be maintained within safety limits. A safety helmet must be worn

when working in an area with overhead or hoisting equipment.

2. Place the machine in an area where the ambient air is as fresh and clean as possible. If necessary,

install a suction conduit. Do not obstruct air vents. Utmost attention must be paid to reducing to the

minimum the possibility of humidity being introduced together with the intake of air.

3. Before connecting any pipes, all blind anges, plugs, covers and hygroscopic substance sachets

must be removed.

4. Air exible hoses must be of the correct dimensions and must be suitable for the operating pressure

exercised. Never utilise worn, damaged or perished exible hoses. Dimensions of the distribution

pipes and connections must be correct and suitable for the operating pressure.

5. Intake air must be free of smoke, vapours and ammable particles, such as those from paint solvent,

which could cause a re to ignite or an internal explosion.

6. Set up the intake air vent so that there is no risk of wide garments being sucked in.

7. Ensure that the exhaust pipe connecting the compressor to the end refrigerator or the compressed

air network can expand with the heat and that it will not be in contact with or in proximity of ammable

material.

8. No external force must be exercised on the air outlet valve: The connected pipe must not be subjected

to stresses.

9. If a remote control is installed, the machine must have a clearly visible notice indicating: DANGER:

10. The machines must be installed in a way that ensures that there is a suitable cooling air ow availa-

5

instruction manual

5

ble, and that the exhaust air will not re-circulate towards the compressor air intake or the cooling air

inow vent.

11. The electrical connections must conform to the applicable standards. The machines must be tted

with a ground connection and protection fuses against short circuits on all phases. Near the compres-

sor, a lockable circuit breaker must be installed.

12. On machines with an automatic start-stop system, or if the function for automatic re-starting after

power interruptions is activated, a notice must be afxed next to the instrument panel, stating the

following “This machine can start suddenly without notice”.

13. In systems with multiple compressors, manual valves must be installed that will isolate each com-

pressor. Never rely on non-return valves for insulating pressurised systems.

14. Do not remove or tamper with safety devices, protections or isolators tted to the machine. Each

pressurised or auxiliary tank installed outside the machine to contain air whose pressure exceeds at-

mospheric pressure, must be protected by a pressure-discharging device or by compulsory devices.

15. Piping and other parts that can reach a temperature exceeding 80 °C (176 °F) and that could acciden-

tally be touched by personnel during normal operations, must have protection or be isolated. Other

high temperature pipes must be clearly marked accordingly.

16. Should the ground not be at or should it be subject to variable inclinations, consult the manufacturer.

Furthermore, read the following safety precautions: Safety precautions during ope-

ration and during maintenance works.

These precautions apply to machinery that use or consume air or inert gasses.

The use of any other gas requires further safety precautions typical of this specic

application and are not included in this publication.

Several precautions are only of a general nature and refer to various types of

equipment and machines; it follows that some instructions may not apply to your

machine.

1.4 Safety precautions during operation

The manufacturer declines any responsibility whatsoever for damages or injuries

that may derive through failing to observe these precautions or normal caution and

through failure in providing the required attention for the installation, operation,

maintenance and repairs, even if not expressly quoted.

instruction manual

6

Precautions during operation

1. Only use couplings and connections for exible hoses of correct types and dimensions. While the

air ows through the exible hose or air pipe, ensure that the open extremity is being held rmly. A

loose extremity can forcibly strike and cause injuries. Ensure that a exible hose is completely de-

pressurised before disconnecting it.

2. Operators starting machines in remote control mode must take opportune precautions to be certain

that no one is checking or working on the machine. For this purpose, a suitable notice must be afxed

on equipment that can be started in remote mode.

3. Never get the machine to operate when there is the risk that fumes, vapours or ammable or toxic

particles could be sucked in.

4. Never get the machine to operate below or above its capacity limits.

5. Workers operating in environments or places in which the noise level pressure reaches or exceeds

90 dB(A) must wear protective hearing devices.

6. Periodically check that:

• All protections are in place and securely fastened

• All exible hoses and/or pipes inside the machine are in good condition, rmly positioned and are not

subject to friction.

• That there are no leaks.

• All fastening elements are properly tightened.

• All current conductors are rm and in optimal condition.

• Safety valves and other pressure attenuation devices are not obstructed by dirt or paint.

• The air outow valve and the air circuit (for example, conduits, couplings, manifolds, valves, exible

hoses, etc.) are in good condition, not worn or being inappropriately used.

7. In air heating systems, should hot air from compressors used for refrigerating be used, for example

to heat a work environment, adopt suitable precautions against pollution and the possible contamina-

tion of air to be breathed.

8. Do not remove, or tamper with, any element of the sound-proong material.

9. Do not remove or tamper with safety devices, protections or isolators tted to the machine. Each

pressurised or auxiliary tank installed outside the machine to contain pressurised air that exceeds at-

mospheric pressure, must be protected by a pressure-discharging device or by compulsory devices.

7

instruction manual

7

Furthermore, read the following safety precautions: Safety precautions during instal-

lation and Safety precautions during maintenance .

These precautions apply to machinery that use or consume air or inert gasses. The

use of any other gas requires further safety precautions typical of this specic ap-

plication and are not included in this publication. Several precautions are only of a

general nature and refer to various types of equipment and machines; it follows that

some instructions may

not apply to your machine.

1.5 Safety precautions during maintenance or repair

Il produttore declina qualsiasi responsabilità per danni o lesioni derivanti dall’inos-

servanza di queste precauzioni o della normale cautela e dalla mancata attenzio-

ne richieste per l’installazione, il funzionamento, la manutenzione e la riparazione,

anche se non espressamente citata.

Precautions during maintenance or repairs

1. Always wear protective goggles.

2. When carrying out maintenance and repair work exclusively use appropriate tools.

3. Only use original spare parts.

4. Any maintenance work must only be carried out once the machine has cooled off.

5. A warning notice such as “Work in progress; do not start” must be afxed on the starting equipment.

6. Operators starting machines in remote control mode must take opportune precautions to be certain

that no one is checking or working on the machine. For this purpose, a suitable notice must be afxed

on the equipment that can be started in remote mode.

7. Before removing any pressurised component, ensure that the machine is properly isolated from all

sources of pressure, and discharge pressure from the whole system.

8. Never use ammable solvents or carbon tetrachloride to clean the components. Implement precau-

tionary safety measures against toxic emissions from cleaning uids.

9. Keep the work place scrupulously clean during maintenance and repair works. Protect against dirt by

covering exposed parts and openings with a clean cloth, paper or adhesive tape

10. Do not carry out welding or other operations that could emanate heat close to the lubrication system.

Oil canisters must be thoroughly cleaned, for example by steam, before performing these operations.

instruction manual

8

Never weld or modify pressure tanks in any way.

11. Should evident signs or suspicions of overheating be found on an internal part of the machine, stop

the machine, but do not open any inspection cover until sufcient time has lapsed for cooling; in this

way the risk of spontaneous combustion of oil vapours upon the inow of air is avoided.

12. Never use a source of light with naked ame to inspect the inside of the machine, the pressurised

tank, etc.

13. Ascertain that no tools, loose parts or rags were left in the machine, or its interior.

14. Maintenance of all adjustment and safety devices must be carried out with due diligence to guarantee

correct operation. They must never be deactivated.

15. Before clearing the machine for use, after maintenance or overhauls, check that the settings relative

to pressures, temperatures and operating timings are correct. Check that all control and stopping

devices are activated and that they operate correctly. If removed, check that the protection of the

compressor drive shaft’s coupling has been reinstalled.

16. Protect the engine, air lter, electrical and adjustment components, etc., to avoid humidity being in-

troduced, for example when cleaning by steam is required.

17. Make sure that all sound-proong material and anti-vibration buffers, for example the sound-proong

material present on the body and in the compressor air inow and outow systems, are in good con-

dition. If damaged, replace with the original material from the manufacturer, to avoid increasing the

sound pressure level.

18. Never use corrosive solvents that could damage the compressed air network, for example poly-

carbon trays.

19. When handling refrigerating substances, the following safety precautions are highlighted:

Never inhale refrigerating vapours. Check that the work area is suitably ventilated; if necessary, adopt

personal protective breathing devices.

Always wear special gloves. In case of skin coming into contact with refrigerant, rinse thoroughly with

water. Should the refrigerating uid come into contact with the skin through the clothing, do not rip

or remove them; pour abundant fresh water on the fabric until there are no more traces of refrigerant

visible; then go to the rst aid room.

20. Hands should be protected to avoid being injured on the scalding parts of the machine, for example

while oil is being drained.

9

instruction manual

9

Furthermore, read the following safety precautions: Safety precautions during in-

stallation and Safety precautions during operation.

These precautions apply to machinery that use or consume air or inert gasses.

The use of any other gas requires further safety precautions typical of this specic

application and are not included in this publication.

Several precautions are only of a general nature and refer to various types of

equipment and machines; it follows that some instructions may not apply to your

machine.

10

2 - GENERAL DESCRIPTION

2.1 Introduction

General

Compressors are air cooled, by two cylinders, single-stage and bi-stage, with oil-less and lubricated pi-

ston. Pumping units are manufactured for effective operating pressures of up to 20 bar, and compressors

for effective pressures of up to 15 bar.

UNITS

3

2

1

4

5

6

5

7

8

1

3

7

8

6

2

9

4

11

instruction manual

11

BASE-MOUNTED

51

63

7

8

4

1

2

3

4

5

9

1012

13

11

instruction manual

12

BASE-MOUNTED, SILENCED

TANK-MOUNTED

12

10

13

14

1

3

12

10

4

2

16

15

17

5

11

11

13

instruction manual

13

TANK-MOUNTED, SILENCED

TANK-MOUNTED, SILENCED WITH DRYER

14

15 16

17

12

10

15

16

12

17

14

18

11

11

instruction manual

14

TANK-MOUNTED, VERTICAL

TANK-MOUNTED, VERTICAL WITH DRYER

16

1

5

4

7

8

6

3

12

10

15

1

16

3

15

2

8

7

4

5

18

17

17

6

11

15

instruction manual

15

WHEEL-MOUNTED

Riferimento Descrizione

1 Cylinder 1

2 Cylinder 2

3 Motor

4 Pumping unit

5Air lter

6Oil ller plug

7 Oil level viewer

8 Oil drain plug

9 Safety valve

10 Gauge

11 Pressure switch circuit breaker

12 Pressure switch

13 Buffer tank

14 Sound-proofed panels

15 Condensate discharge

16 Air tank

17 Air delivery

18 Dryer

19 Pressure reducer

20 Handle

20 12

19

15

4

5

12

3

16

6

17

10

11

instruction manual

16

Versions

The compressor unit includes:

• Base

• Cylinders

• Air lter

• Fan

• Pressure switch

• Safety valve (on some models)

• Flanged electrical motor

The units assembled on the base include:

• Compressor unit

• Air lter

• Pressure switch

• Fan

• Safety valve

• Gauge

• Flanged electrical motor

• Buffer tank

• Sound-proong panelling (on some models)

The unit mounted on the base is completely operative and equipped with pressure switch and buffer tank

The units assembled on the tank include:

• Compressor unit

• Air lter

• Pressure switch

• Fan

• Safety valve

• Gauge

• Flanged electrical motor

• Sound-proong panelling (on some models)

17

instruction manual

17

• Tank, both horizontal and vertical

The Full Feature units (assembled on the tank with dryer) include:

• Compressor unit

• Air lter

• Pressure switch

• Fan

• Safety valve

• Gauge

• Flanged electrical motor

• Sound-proong panelling

• Tank, both horizontal and vertical

• Dryer with automatic condensate discharge

The Full Feature compressor is a compressor mounted on a tank equipped with a refrigerating gas dryer,

with lter DD and PD. These dryers remove the humidity from the compressed air, cooling it down to a

temperature close to freezing point. This causes condensate to form. The condensate gets automatically

discharged. The air gets heated before owing out of the dryer.

2.2 Options

The compressors can be integrated with the following options. For detailed information please refer to

the Assistance Centre.

instruction manual

18

Reference Description

Electronic condensate discharge

Control unit for star-triangle starting

Galvanised tank.

AD2000 galvanised tank

2.3 Air ow

Flow diagram references

Riferimento Descrizione

AF Air lter

AR Tank

AV/ AV1/AV2 Air outlet valves

CV Non-return valve

DD Dryer lter

DP Oil drain plug

DM Condensate discharge valve

FC Oil ller plug

FN Fan

GP Gauge

MMotor

MDR Pressure switch

PD Dryer lter

S1 On/Off switch

SG Oil level viewer

SV Safety valve

US Discharge silencer

Y1 Solenoid valve

This manual suits for next models

31

Other Aerotec Air Compressor manuals

Popular Air Compressor manuals by other brands

Harbor Freight Tools

Harbor Freight Tools Central Pneumatic 40400 Assembly and operating instructions

Emerson

Emerson Copeland Scroll ZR KC Series Bulletin

Will Burt

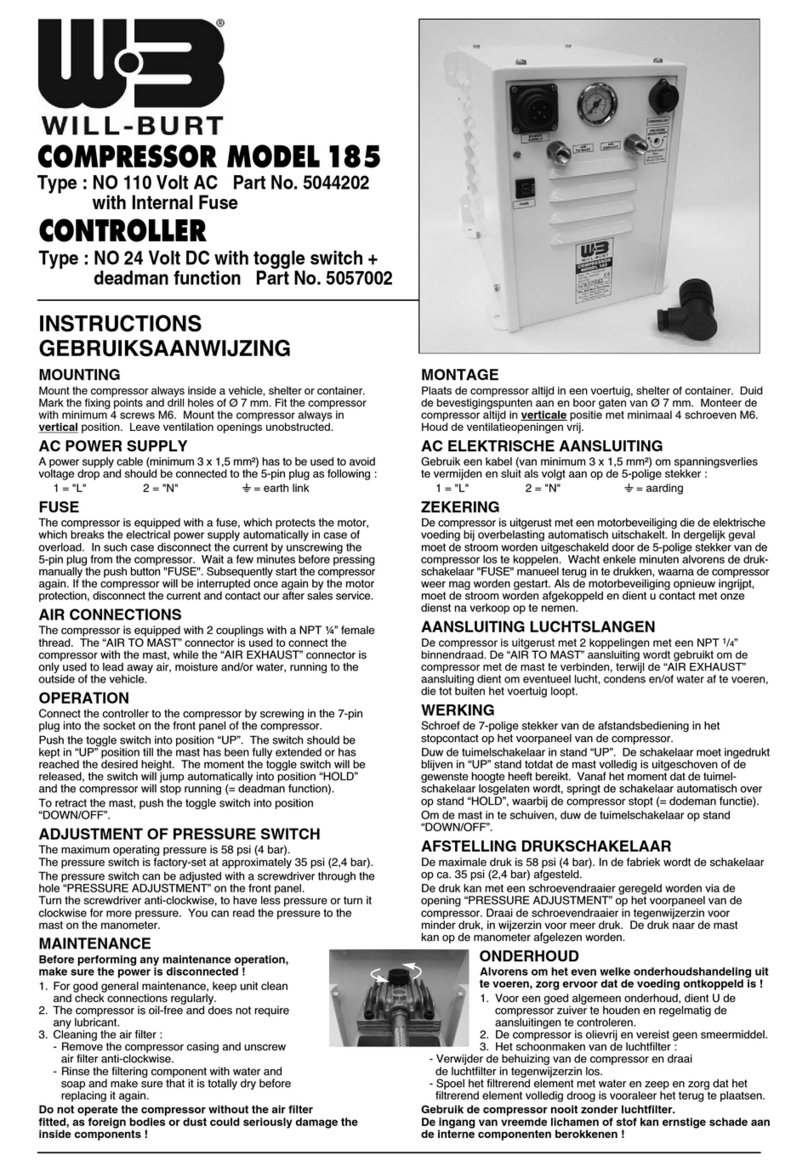

Will Burt 185 instructions

Feider Machines

Feider Machines FC6LS instruction manual

XTM

XTM 645860 owner's manual

RIDGID

RIDGID GP90150A Operator's manual

Bushranger

Bushranger Max Air III 55x23 owner's manual

Fieldmann

Fieldmann FDAK 70205-0 user manual

Atlas Copco

Atlas Copco XA146 Dd instruction manual

Prebena

Prebena TWINMAX 420 Original instructions

Scheppach

Scheppach HC24Si Translation from the original instruction manual

Sears

Sears 919.72633 owner's manual