Aerotec CSX600 User manual

Impact driver 1/2" CSX600

English

Français

20

Dansk 29

Čeština37

Slovenčina

45

Italiano53

Magyar61

Hrvatski

69

Slovenščina

77

Bosanski

85

©pro)SALES GmbH - Ferdinand-Porsche-Straße 16 - 63500 Seligenstadt

Art. no. 2010129

1/2" mount

Labelling

Product safety – prohibition signs:

According to

European Union

standards

Prohibition sign

Wearing loose-

fitting clothes is

prohibited!

Wearing jewelry etc

is prohibited.

Warning – mandatory signs:

ATTENTION/WAR

NING

Observe

Operating Manual

Wear hearing

protection

Wear protective

goggles

Environment safety:

Do not dispose

of waste into

the environment

Cardboard packaging can be

returned at designated

recycling points.

Damaged and/or disposable

electric or electronic

equipment must be returned

at the designated recycling

points.

Device:

Impact driver 1/2" CSX600

Specifications:

Impact driver 1/2" CSX600

Operating pressure: 6.3

bar

Air consumption: 120 l/min

Threaded connection:

1/4“ IT

Drive: 1/2“

Max. torque 600 Nm

Idle speed: 9000 min-1

Recomm. hose diameter 10 mm

Sound power level: 93 dB (A)

Weight: 1.5 kg

Article no. 2010129

Delivery scope:

1x Impact driver 1/2" CSX600

1 x SK nipple 1/4“ ET

1 x Operating Manual

EN

Complaints/spare-part orders will be processed quickly and

unbureaucratically. Please use the following contact details

Phone: +49 61 82 / 99 38 7

- 0

Fax: +49 61 82 / 99 38

387 - 20

E-Mail:

Please read this operating manual carefully

prior to commissioning the device.

EC Declaration of Conformity

Herewith, we,

pro)SALES GmbH

Ferdinand-Porsche-Straße 16

63500 Seligenstadt / Germany, state

That the devices described below, on

the basis of its design and

construction, as well as the version

that we have put into circulation,

corresponds with the relevant

fundamental health and safety

requirements of the EC directives.

This certificate becomes void if the

devices are modified without our

approval.

Device designation:

Impact driver 1/2" CSX600,

Article no.: 2010129

Date/Manufacturer signature:

22.02.2011

Details of the signatory: Mr.

Markert, executive director

Relevant EC directive:

2006/42 EC

Applied harmonized standards:

EN 792; EN ISO 15744;

EN28662-1, EN ISO 8662-7

General safety information:

Safety information! If the

following information is not

observed, this can cause

injuries.

Read the pneumatic tool instructions

very carefully prior to commissioning.

All operators must be fully and

sufficiently informed on how to

operate pneumatic tools. Only

qualified and trained technicians are

allowed

to do servicing and repair work.

For the operation of impact drivers,

only impact sockets must be used.

Never use impact if the drive square

is worn or damaged. Prior to every

use, check that the drive square at

the impact sockets, the extensions

or the spindle of the impact driver is

not worn.

Make sure that the operator has a

solid and secure standing and

working position prior to using the

tool.

Prior to every use, check that the

torque is adjusted correctly. If the

torque is adjusted incorrectly, this

can cause uncontrollable tool

movements and the screw to

rupture.

Make sure prior to every start-up

that the reversible switch is in the

correct position.

Check the pneumatic hose and all

connections regularly for signs of

wear or damages.

Hold the tool on the handle only,

never on the hose.

Never exceed the recommended

maximum operating pressure (6.3

bar)

The tool is neither earthed not

electrically insulated. Never use the

tool where it could come into contact

with electricity.

It is advisable to disconnect the air

supply when replacing impact

sockets; the release must not be

actuated during this process.

When loosening screw connections,

make sure to have sufficient scope to

the back to prevent the guiding hand

from getting crushed.

If you notice any malfunctions or

irregular power prior to use, stop

using the tool immediately and

maintain or repair the tool.

Do not use overly long hoses to

prevent tripping hazards.

Read the compressor operating

manual and observe the safety

instructions for operating the

compressor.

ALWAYS use certified protective

goggles and hearing protection-

Take off watches, rings or similarly

interfering items. Loose clothing or

jewelry could get entangled in the air

compressor or the air device which

could cause severe injuries.

The trigger must not be operated

when the device is connected to the

air supply.

Disconnect the air supply from the

device when it is not used. NEVER

replace accessory parts and NEVER

execute maintenance work when the

device is connected to the air

supply.

Maintain the device thoroughly and

follow the instructions on greasing

and maintenance.

Do not damage the hoses and

connectors by carrying the device

holding the hose or disconnecting

the hose by tugging from the air

supply. Prevent the hose from being

exposed to heat or sharp edges.

The hose should be replaced if it is

damaged or worn.

NEVER operate the device with an

air pressure exceeding 6.3 bar. Use

a pressure regulator that reduces

the pressure to 6.3 bar.

Operate the device at a safe

distance from humans and animals

AT ALL TIMES.

Prior to start-up:

Air supply

Grease the device prior to operation

(see last page), we recommend to

use an oil-mist lubricator.

Assembly

Always disconnect the air-supply

hose before mounting/dismounting

impact sockets or attachments

to/from the device.

Safety information!

Wear protective goggles!

Wear hearing protection!

Make sure that only compressed air

free of condensate is used for

operation. It is sufficient to slot in a

water trap filter.

Start the air compressor. The

maximum operative air pressure for

the tool is 6.3 bar; the operative

pressure can be adjusted via a

pressure regulator at your

compressor.

The power (torque) of impact drivers

in primary working conditions is

determined mainly by 3 factors:

a) the operative pressure used.

b) the duration of the process at the

screw connection. Usually, the

average operative time for a screw

connection is 3-5 seconds.

Maintenance and care

Greasing

1. Disconnect the impact driver

from its air supply.

2. Add 4-6 drops of a pneumatic

or corresponding oil into the air

intake while pushing the trigger.

3. Then connect the device again

to the air supply and let it run

for approx. 30 seconds to

remove surplus oil.

This greasing process contributes to

reduce humidity, dust and dirt that

will accumulate in all air devices at

some point, thereby reducing their

power. The best protection would

be to use an integrated oil vessel.

Remove the air hose every 4

months or if the impact drive is used

rarely and fill an large amount of

pneumatic oil into the air intake.

Then reconnect the air hose and let

the impact driver run for approx. 20

seconds to clean the air device

engine. Follow the greasing

instructions after cleaning is

completed.

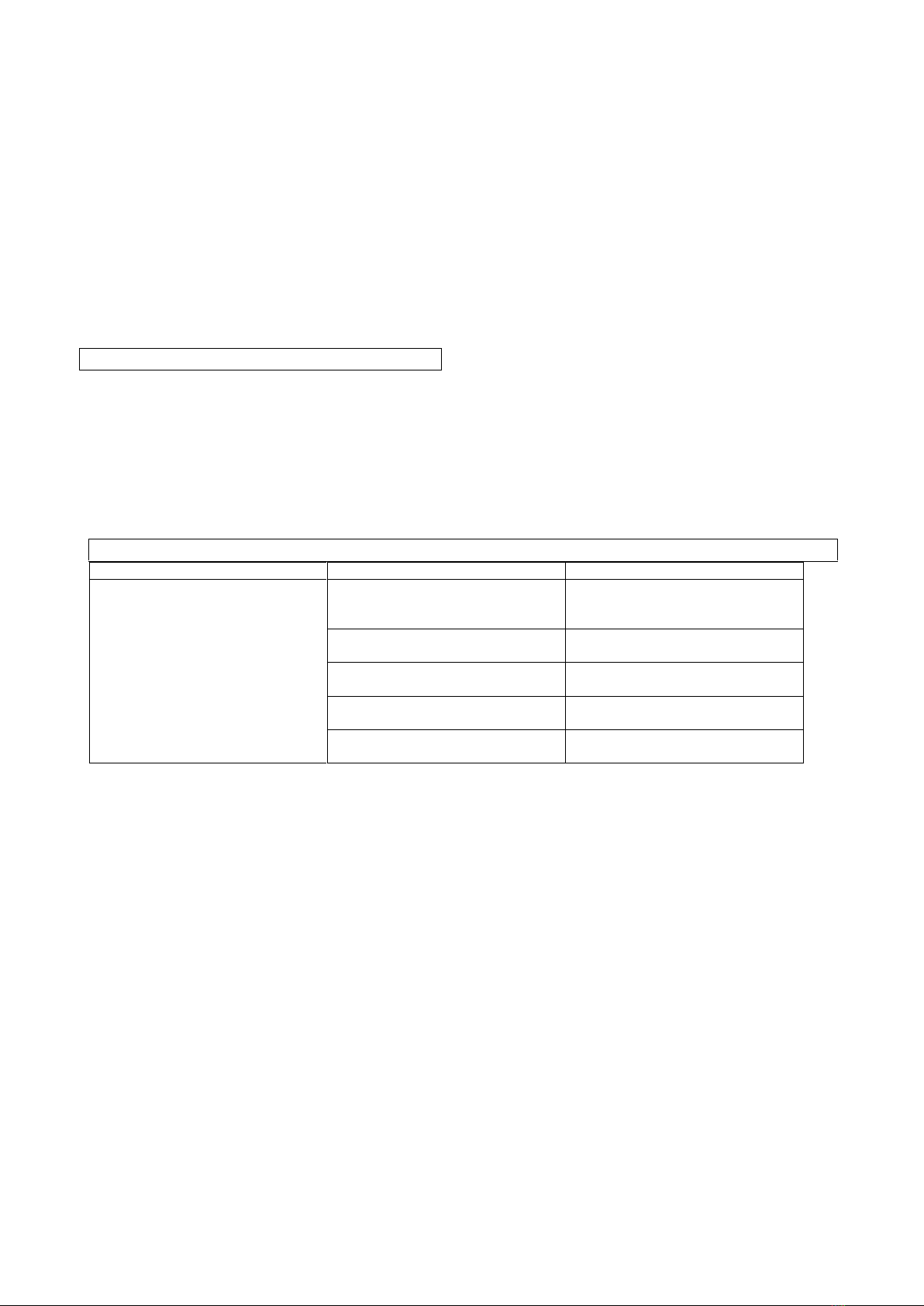

Troubleshooting

Problem

Possible cause

Solving the problem

Insufficient air pressure

Hose diameter too small

Check the air pressure at

the air intake. It must be

6.3 bar at least.

Adjusted air pressure

insufficient

Rise the air pressure to

6.3 bar.

Impact driver must be

greased.

See maintenance.

Impact driver must be

cleaned.

See maintenance.

The impact driver does not

work or runs slowly.

Air hose is leaking

Check all screw

connections

POS

Number

Designation

Quantity

01

--

Housing

1

03

--

Jack

1

04

NC4610P0

2

Rotor

1

05

NC4610P0

5

Rotor blade

1

06

NC4610P0

5

End plate

1

07

NC4610P0

7

Bearing

1

08

NC4610P0

8

End plate

1

9

NC4610P0

9

Bearing

1

10

NC4610P1

0

Impact plate

11

--

Striker

1

12

NC4610P1

2

Picker

1

13

NC4610P1

3

Bouncing pin

2

14

NC4610P1

4

Sealing

1

15

NC4610P1

5

Switch

1

16

NC4610P1

6

Head

1

17

NC4610P1

7

Sealing

1

18

NC4610P1

8

Spring

1

19

NC4610P1

9

Spring

1

20

NC4610P2

0

O ring

1

21

NC4610P2

1

Terminal

1

3 speeds adjustable for clockwise

rotation.

1 speed adjustable for anti-clockwise

rotation.

The speeds can easily be changed with

the switch.

Image 1:

1. Tool mount with drive square

2. Pneumatic connection/compressed air supply

3. Reversing switch

4. Trigger

2

3

Changing direction of rotation:

The direction of rotation can easily be changed via sliding

switch at the device.

The change is executed via pos. 3 into the designated

arrow directions

Recommended use:

1. Compressor

2. Filter unit with oil-

mist lubricator

3. Stop cock

4. Pneumatic device

1

4

This manual suits for next models

1

Table of contents