Aerotech ABL1500Z User manual

Revision: 1.03.00

ABL1500Z Hardware Manual

Global Technical Support

Go to www.aerotech.com/global-technical-support for information and support about your Aerotech products. The website

provides downloadable resources (such as up-to-date software, product manuals, and Help files), training schedules, and

PC-to-PC remote technical support. You can also complete Product Return (RMA) forms and get information about repairs

and spare or replacement parts. For immediate help, contact a service office or your sales representative. Have your

customer order number available before you call or include it in your email.

United States (World Headquarters)

Phone: +1-412-967-6440

Fax: +1-412-967-6870

Email: service@aerotech.com

101 Zeta Drive

Pittsburgh, PA 15238-2811

www.aerotech.com

United Kingdom Japan

Phone: +44 (0)1256 855055

Fax: +44 (0)1256 855649

Email: service@aerotech.co.uk

Phone: +81 (0)50 5830 6814

Fax: +81 (0)43 306 3773

Email: service@aerotechkk.co.jp

Germany China

Phone: +49 (0)911 967 9370

Fax: +49 (0)911 967 93720

Email: service@aerotechgmbh.de

Phone: +86 (21) 5508 6731

Email: service@aerotech.com

France Taiwan

Phone: +33 2 37 21 87 65

Email: service@aerotech.co.uk

Phone: +886 (0)2 8751 6690

Email: service@aerotech.tw

This manual contains proprietary information and may not be reproduced, disclosed, or used in whole or in part without the

express written permission of Aerotech, Inc. Product names mentioned herein are used for identification purposes only and

may be trademarks of their respective companies.

Copyright © 2008-2018, Aerotech, Inc., All rights reserved.

ABL1500Z Hardware Manual Table of Contents

Table of Contents

ABL1500Z Hardware Manual 1

Table of Contents 3

List of Figures 4

List of Tables 5

Safety Procedures and Warnings 7

EU Declaration of Incorporation 9

Chapter 1: Overview 11

1.1. Environmental Specifications 12

1.2. Accuracy and Temperature Effects 12

1.3. Basic Specifications 13

1.4. Air Requirements 14

Chapter 2: Installation 17

2.1. Unpacking and Handling the Stage 17

2.2. Dimensions 19

2.3. Securing the Stage to the Mounting Surface 20

2.4. Attaching the Payload to the Stage 22

Load Capability 22

2.5. Setting Up the Pneumatic Counterbalance 24

Chapter 3: Electrical Specifications and Installation 29

3.1. Motor and Feedback Connectors 30

3.2. Motor and Feedback Wiring 33

3.3. Motor and Feedback Specifications 34

3.4. Limits, Marker, and Machine Direction 36

3.5. Motor and Feedback Phasing 37

Chapter 4: Maintenance 39

4.1. Service and Inspection Schedule 39

4.2. Cleaning and Lubrication 39

4.2.1. Cleaning Process 40

4.3. Troubleshooting 42

Appendix A: Warranty and Field Service 43

Appendix B: Revision History 45

Index 47

www.aerotech.com 3

Table of Contents ABL1500Z Hardware Manual

List of Figures

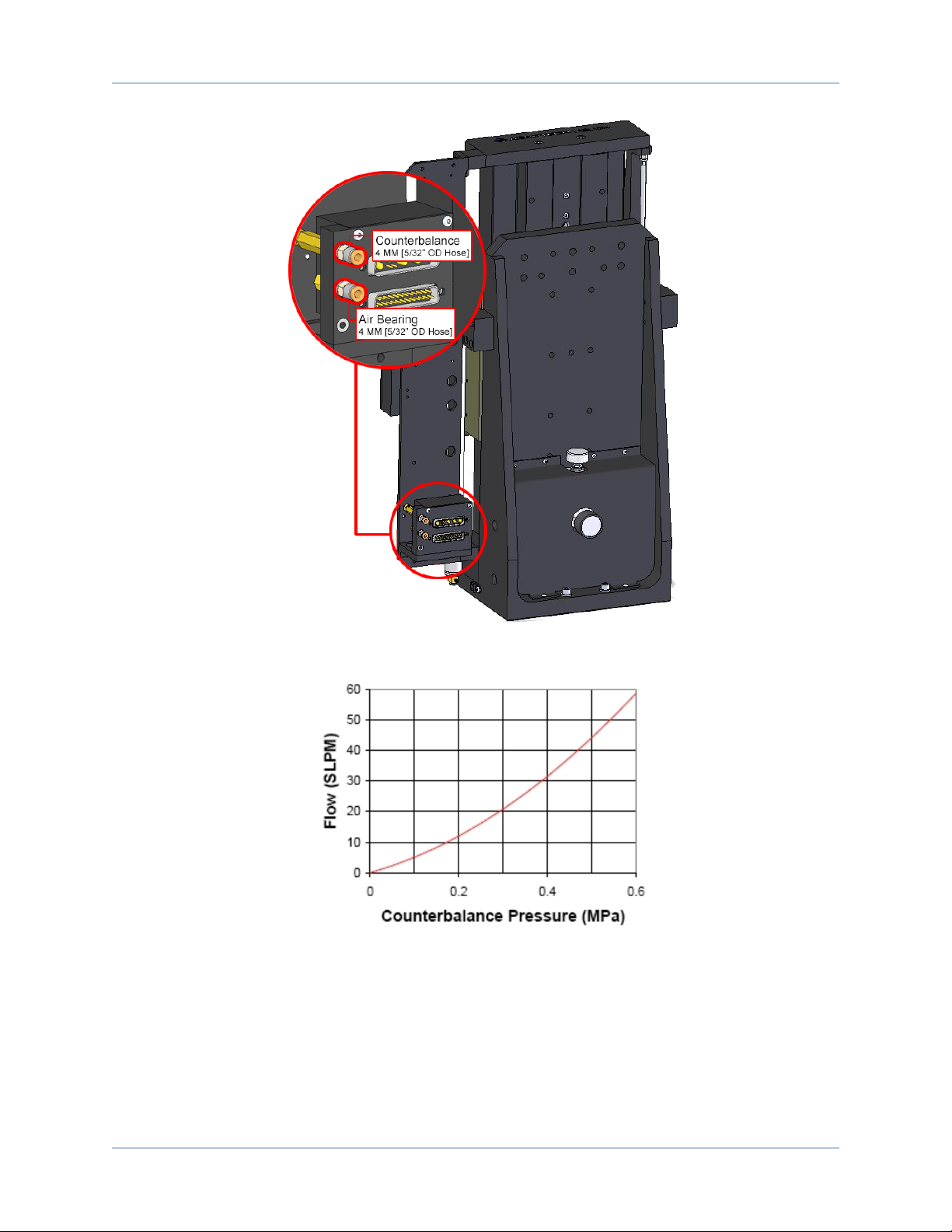

Figure 1-1: Air Fitting Locations for Air Bearing 15

Figure 1-2: Counterbalance Air Flow vs. Counterbalance Pressure 15

Figure 2-1: Lifting Features and Shipping Clamps 18

Figure 2-2: ABL1500Z Dimensions 19

Figure 2-3: Surface Mounting Screws 21

Figure 2-4: Cantilevered Load Capability (Pitch) for Various Peak Accelerations 22

Figure 2-5: Offset Load Capability (Yaw) for Various Peak Applications 23

Figure 2-6: Cantilever and Offset Loading Diagram 23

Figure 2-7: Counterbalance Pressure vs. External Payload 24

Figure 2-8: Connections for Air Bearing and Counterbalance 25

Figure 2-9: Shipping Bracket 26

Figure 3-1: Connector Locations 29

Figure 3-2: Motor and Feedback Wiring 33

Figure 3-3: Machine Direction 36

Figure 3-4: Hall Phasing 37

Figure 3-5: Analog Encoder Phasing Reference Diagram 38

Figure 3-6: Encoder Phasing Reference Diagram (Standard) 38

Figure 4-1: Air Bearing Surfaces and Encoder Scales Require Periodic Cleaning 41

4 www.aerotech.com

ABL1500Z Hardware Manual Table of Contents

List of Tables

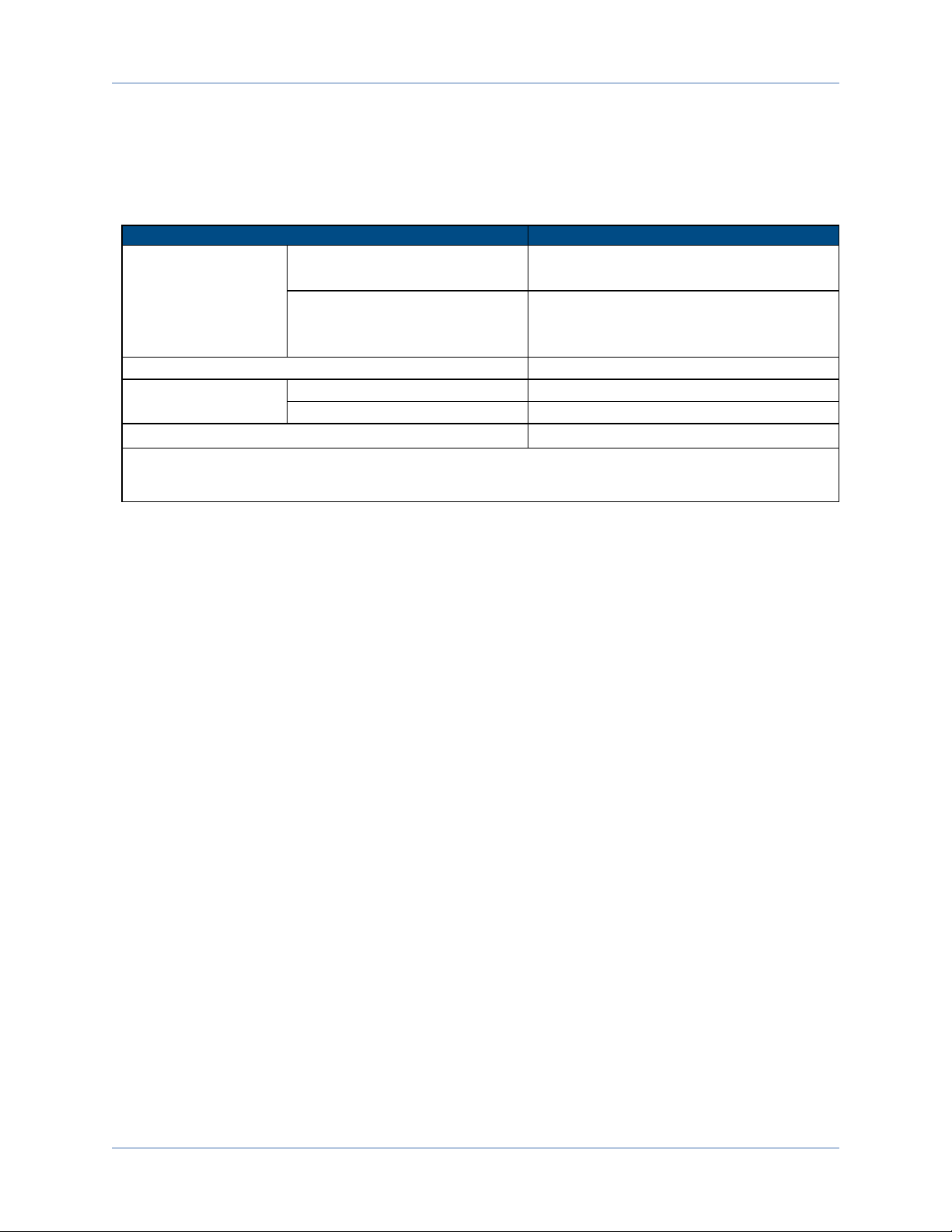

Table 1-1: Model Numbers and Ordering Options 11

Table 1-2: Environmental Specifications 12

Table 1-3: ABL1500Z Series Specifications 13

Table 1-4: Air Specifications 14

Table 3-1: Motor Connector Pinouts 31

Table 3-2: Feedback Connector Pinouts 32

Table 3-3: Feedback Specifications 34

Table 3-4: Encoder Specifications 35

Table 3-5: BLMC-192 Motor Specifications 35

Table 4-1: Recommended Cleaning Solvents 39

www.aerotech.com 5

Table of Contents ABL1500Z Hardware Manual

6 www.aerotech.com

This page intentionally left blank.

ABL1500Z Hardware Manual Safety

Safety Procedures and Warnings

Read this manual in its entirety before installing, operating, or servicing this product. If you do not understand

the information contained herein, contact an Aerotech representative before proceeding. Strictly adhere to

the statements given in this section and other handling, use, and operational information given throughout

the manual to avoid injury to you and damage to the equipment.

The following statements apply wherever the Warning or Danger symbol appears within this manual. Failure

to observe these precautions could result in serious injury to those individuals performing the procedures

and/or damage to the equipment.

D A N G E R : This product contains potentially lethal voltages. To reduce the possibility of

electrical shock, bodily injury, or death the following precautions must be followed.

1. Access to the ABL1500Z and component parts must be restricted while connected to a

power source.

2. Do not connect or disconnect any electrical components or connecting cables while

connected to a power source.

3. Disconnect electrical power before servicing equipment.

4. All components must be properly grounded in accordance with local electrical safety

requirements.

5. Operator safeguarding requirements must be addressed during final integration of the

product.

6. PINCHPOINT! Keep Hands Clear while the stage is in motion.

W A R N I N G : To minimize the possibility of electrical shock, bodily injury or death the

following precautions must be followed.

1. Moving parts can cause crushing or shearing injuries. Access to all stage and motor parts

must be restricted while connected to a power source.

2. Cables can pose a tripping hazard. Securely mount and position all system cables to avoid

potential hazards.

3. Do not expose this product to environments or conditions outside of the listed

specifications. Exceeding environmental or operating specifications can cause damage to

the equipment.

4. The ABL1500Z stage must be mounted securely. Improper mounting can result in injury

and damage to the equipment.

5. Use care when moving the ABL1500Z stage. Lifting or transporting the ABL1500Z stage

improperly can result in injury or damage to the ABL1500Z.

6. This product is intended for light industrial manufacturing or laboratory use. Use of this

product for unintended applications can result in injury and damage to the equipment.

7. If the product is used in a manner not specified by the manufacturer, the protection

provided by the product can be impaired and result in damage, shock, injury, or death.

8. The stage forcer temperature may exceed 75°C.

9. Operators must be trained before operating this equipment.

10. All service and maintenance must be performed by qualified personnel.

11. Eye protection must be worn when in the proximity of compressed air components.

www.aerotech.com 7

Safety ABL1500Z Hardware Manual

8 www.aerotech.com

This page intentionally left blank.

ABL1500Z Hardware Manual Declaration of Conformity

EU Declaration of Incorporation

Manufacturer:

Aerotech, Inc.

101 Zeta Drive

Pittsburgh, PA 15238-2811

USA

herewith declares that the product:

ABL1500Z Stage

is intended to be incorporated into machinery to constitute machinery covered by the Directive

2006/42/EC as amended; and that the following harmonized European standards have been

applied:

EN ISO 12100:2010 Safety of machinery - Basic concepts, general principles for

design

EN 60204-1:2010 Safety of machinery - Electrical equipment of machines - Part

1:General requirements

and further more declares that

it is not allowed to put the equipment into service until the machinery into which it is to be

incorporated or of which it is to be a component has been found and declared to be in con-

formity with the provisions of the Directive 2006/42/EC and with national implementing

legislation, i.e., as a whole, including the equipment referred to in this Declaration.

This is to certify that the aforementioned product is in accordance with the applicable requirements of the fol-

lowing Directive(s):

2011/65/EU RoHS2 Directive

Authorized Representative:

Simon Smith, European Director

Address:

Aerotech Ltd

The Old Brick Kiln, Ramsdell, Tadley

Hampshire RG26 5PR

UK

Name

/ Alex Weibel

Position

Engineer Verifying Compliance

Location

Pittsburgh, PA

Date

12/21/2018

www.aerotech.com 9

Declaration of Conformity ABL1500Z Hardware Manual

10 www.aerotech.com

This page intentionally left blank.

ABL1500Z Hardware Manual Overview

Chapter 1: Overview

N O T E : Aerotech continually improves its product offerings; listed options may be superseded at any

time. All drawings and illustrations are for reference only and were complete and accurate as of this

manual’s release. Refer to www.aerotech.com for the most up-to-date information.

Table 1-1: Model Numbers and Ordering Options

ABL1500Z Series Linear Air-Bearing Stage

-050 50 mm travel

-100 100 mm travel

-150 150 mm travel

-200 200 mm travel

Feedback (Required)

-E1 Incremental linear encoder, 1 Vpp amplified sine output

-E2 Incremental linear encoder, 0.1 µm TTL line driver output

-E3 High-accuracy incremental linear encoder, 1 Vpp amplified sine output

Cable Management (Required)

-CMS1 Single axis cable management system

-CMS2 Cable management system for ZT assembly

Metrology (Required)

-PL1 Metrology, uncalibrated with performance plots

-PL2 Metrology, calibrated (HALAR) with performance plots

Accessories (to be ordered as separate line item)

ALIGN-NPA Non-precision XY assembly

ALIGN-PA10 XY assembly; 10 arc sec orthogonality. Alignment to within 7 microns orthogonality for

short travel stages.

ALIGN-PA5 XY assembly; 5 arc sec orthogonality. Alignment to within 3 microns orthogonality for

short travel stages.

ABF Air-bearing filtration kit

www.aerotech.com Chapter 1 11

Overview ABL1500Z Hardware Manual

1.1. Environmental Specifications

W A R N I N G : Do not expose this product to environments or conditions outside of the listed

specifications. Exceeding environmental or operating specifications can cause damage to the

equipment.

Table 1-2: Environmental Specifications

Ambient

Temperature

Operating: 16° to 25° C (61° to 77° F)

The optimal operating temperature is 20° C ±2° C (68° F ±4° F). If at any time the

operating temperature deviates from 20° C degradation in performance could occur.

Storage: 0° to 40° C (32° to 104° F) in original shipping packaging

Humidity

Operating: 20% to 60% RH

Storage: 10% to 70% RH, non-condensing in original packaging. The stage should be

packaged with desiccant if it is to be stored for an extended time.

Altitude

Operating: 0 m to 2,000 m (0 ft to 6,562 ft) above sea level

Contact Aerotech if your specific application involves use above 2,000 m or below sea

level.

Vibration

Use the system in a low vibration environment. Excessive floor or acoustical vibration

can affect system performance. Contact Aerotech for information regarding your

specific application.

Protection

Rating

ABL1500Z stages are not suited for dusty or wet environments. This equates to an

ingress protection rating of IP00.

Use Indoor use only

1.2. Accuracy and Temperature Effects

Due to the small clearances in the air bearing design, extreme temperature environments could cause a

decrease in performance or permanent damage to the stage. Standard Aerotech air-bearing stages are

designed for and built in a 20°C (68°F) environment. The environmental temperature must be controlled to

within 0.25°C per 24 hours to ensure that the ABL1500Z specifications are repeatable over an extended

period of time. The severity of temperature effects on all specifications depends on many different

environmental conditions, including how the ABL1500Z is mounted. Contact the factory for more details.

The -E1 and -E2 encoder scale in the ABL1500Z stage has a coefficient of thermal expansion (CTE) of

3.25 x 10-6 / °C. The -E3 encoder scale has a CTE of 7.5 x 10-6 / C. As the stage deviates from 20°C, travel

of the stage as seen by the encoder will change per the appropriate thermal expansion rate.

12 Chapter 1 www.aerotech.com

ABL1500Z Hardware Manual Overview

1.3. Basic Specifications

Table 1-3: ABL1500Z Series Specifications

Basic Model ABL15005Z-

050

ABL15010Z-

100

ABL15015Z-

150

ABL15020Z-

200

Travel 50 mm 100 mm 150 mm 200 mm

Accuracy (1)

-E1 Calibrated ±0.3 µm ±0.3 µm ±0.4 µm ±0.5 µm

Standard ±2.0 µm ±3.0 µm ±5.0 µm ±8.0 µm

-E3 Calibrated ±0.2 µm ±0.2 µm ±0.3 µm ±0.5 µm

Standard ±1.5 µm ±2.5 µm ±4.0 µm ±6.0 µm

Repeatability (Bi-

Directional) (1)

-E1 ±0.1 µm ±0.1 µm ±0.15 µm ±0.2 µm

-E3 ±0.1 µm ±0.1 µm ±0.15 µm ±0.2 µm

Straightness (1) ±0.4 µm ±0.6 µm ±0.8 µm ±1.0 µm

Flatness (1) ±0.4 µm ±0.6 µm ±0.8 µm ±1.0 µm

Pitch ±1 arc sec ±1.5 arc sec ±2 arc sec ±2.5 arc sec

Roll ±1 arc sec ±1.5 arc sec ±2 arc sec ±2.5 arc sec

Yaw ±1 arc sec ±1.5 arc sec ±2 arc sec ±2.5 arc sec

Maximum Speed 300 mm/s

Maximum Acceleration 2 g (no load)

Maximum Force (Continuous) 93.6 N

Load Capacity(2) 15.0 kg

Operating Pressure(3) 80 psi ±5 psig

Air Consumption(4) Stage: 24 - 30 SLPM @ 551 kPa;

Counterbalance: 60 SLPM max

Moving Mass (no load) 5.9 kg

Stage Mass 23.8 kg 26.6 kg 28.5 kg 30.5 kg

Material Aluminum

Mean Time Between Failure 20,000 Hours

(1) Certified with each stage.

(2) Axis orientation for on-axis loading is listed (refer to Section 2.4. for offset loading behavior).

(3) To protect air bearing against under-pressure, an in-line pressure switch tied to the motion controller/amplifier E-Stop is

recommended.

(4) Air supply must be clean, dry to 0° F dew point and filtered to 0.25 μm or better. Recommend nitrogen at 99.9% purity.

NOTES:

lSpecifications are for single-axis systems measured 25 mm above the tabletop; performance of multi-axis system is payload

and workpoint dependent. Consult the Aerotech factory for multi-axis or non-standard applications.

www.aerotech.com Chapter 1 13

Overview ABL1500Z Hardware Manual

1.4. Air Requirements

The quality of the air that you supply to the stage is important to the operation of the stage. Aerotech

recommends that you connect the air supply to the air inlet with a polyurethane air hose.

Table 1-4: Air Specifications

Description

Air Quality

Nitrogen(1) l99.99% pure

lfiltered(2) to 0.25 microns

Compressed Air

lfiltered(2) to 0.25 microns

ldry to 0º F dew point

loil free

Operating Air Pressure 80 psi ± 5 psi (517 to 551 kPa)

Air Consumption Stage 24 - 30 SLPM

Counterbalance 60 SLPM maximum

Air Inlet Fitting(3) 4 mm or 5/32" OD Hose

(1) Recommended

(2) The filtration requirement is to prevent particles from clogging the air bearing openings.

(3) Aerotech recommends using a polyurethane air hose.

Aerotech also recommends that you install a pressure switch (P/N: MCA03094) tied to the motion

controller's emergency stop (ESTOP)that will remove power to the air bearing if pressure drops below 40 psi

(a drop in pressure could result in contact between bearing surfaces which could cause damage to the

surfaces). For easier air-supply setup, you can purchase pneumatic kits and filter/filter-dryer kits from

Aerotech. Aerotech’s ABF Air Filtration Unit incorporates air filtration plus a pressure monitoring switch.

The pneumatic counterbalance pressure supply is determined by the amount of payload carried by the stage

(Figure 1-1 and Figure 1-2; for setup, refer to Section 2.5.).

14 Chapter 1 www.aerotech.com

ABL1500Z Hardware Manual Overview

Figure 1-1: Air Fitting Locations for Air Bearing

Figure 1-2: Counterbalance Air Flow vs. Counterbalance Pressure

www.aerotech.com Chapter 1 15

Overview ABL1500Z Hardware Manual

16 Chapter 1 www.aerotech.com

This page intentionally left blank.

ABL1500Z Hardware Manual Mechanical Specifications and Installation

Chapter 2: Installation

W A R N I N G : ABL1500Z installation must be in accordance to instructions provided by this

manual and any accompanying documentation. Failure to follow these instructions could result

in injury or damage to the equipment.

2.1. Unpacking and Handling the Stage

D A N G E R / H E A V Y : Do not attempt to manually lift the ABL1500Z. Refer to for stage mass

specifications.

lLift only with the supplied lifting hardware and lifting straps.

lUse the eyebolts in conjunction with lifting straps.

lThe lifting straps should be configured to pull on the eyebolts in the vertical direction only.

lDo not use the tabletop or cable as lifting points.

W A R N I N G : It is the customer's responsibility to safely and carefully lift the stage.

lMake sure that all moving parts are secure before moving the ABL1500Z. Unsecured

moving parts may shift and cause bodily injury.

lImproper handling could adversely affect the performance of the ABL1500Z. Use care

when moving the ABL1500Z.

N O T E : If any damage has occurred during shipping, report it immediately.

Carefully remove the ABL1500Zfrom its protective shipping container. Use the lifting equipment to gently

set the ABL1500Z on a smooth, flat, and clean surface.

Before operating the ABL1500Z, it is important to let it stabilize at room temperature for at least 12 hours.

Allowing it to stabilize to room temperature will ensure that all of the alignments, preloads, and tolerances are

the same as they were when tested at Aerotech. Use compressed nitrogen or clean, dry, oil-less air to

remove any dust or debris that has collected during shipping.

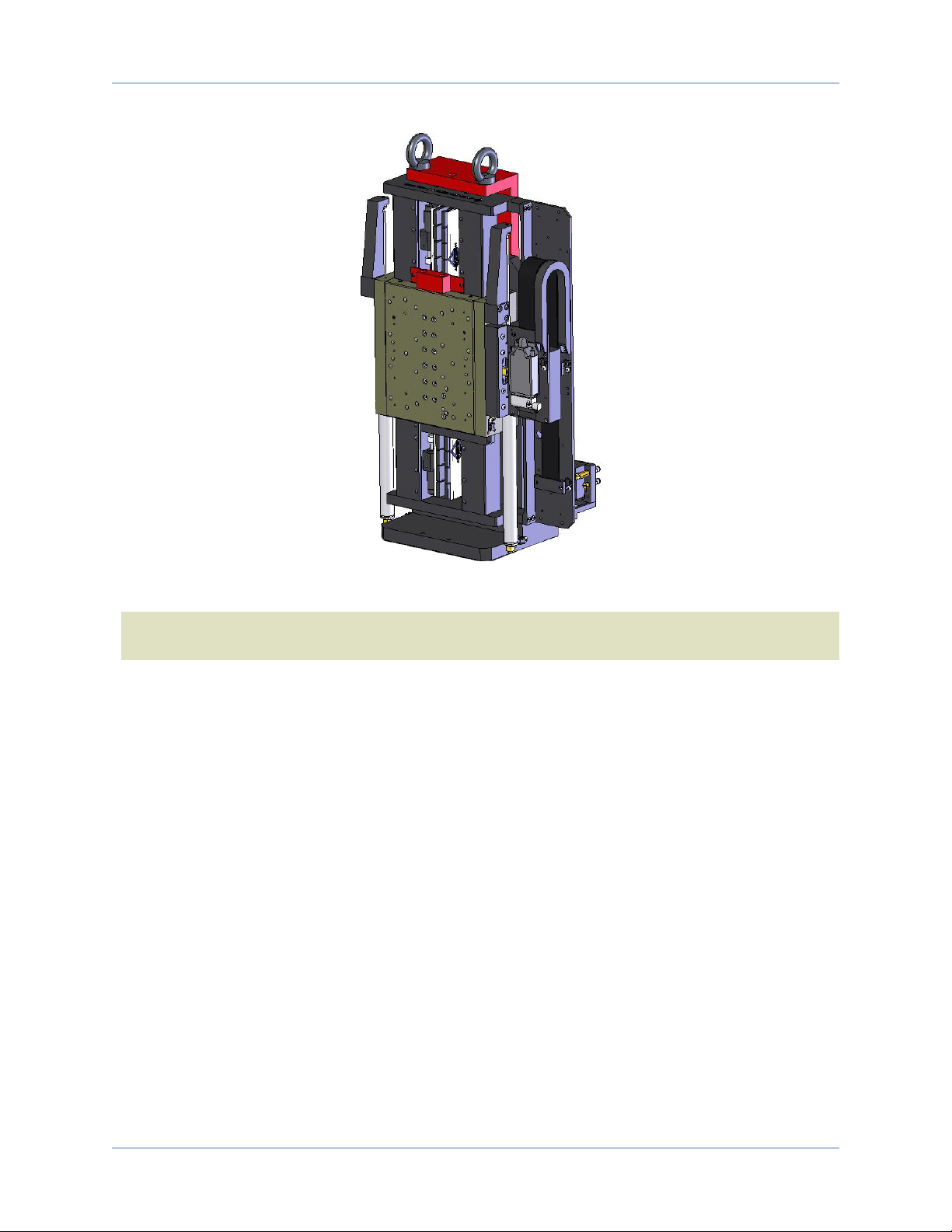

Lifting Hardware

ABL1500Z stages come equipped with lifting bars and eyebolts attached to the stage as shown in Figure 2-1.

For multi-axis assemblies, always lift the system by the lower axis. Lifting by the upper axis may disturb

precision alignments on the system.

Each ABL1500Z has a label listing the system part number and serial number. These numbers contain

information necessary for maintaining or updating system hardware and software. Locate this label and

record the information for later reference.

Shipping Clamps

Red, anodized aluminum shipping brackets have been installed to prevent unwanted motion and potential

damage from occurring during shipment. The brackets must be removed before the ABL1500Z can be

operated. Retain the brackets and hardware for future use.

W A R N I N G : Do not attempt to move the carriage (or table top) of the ABL1500Z until the

shipping brackets have been removed. Moving the carriage with the shipping brackets installed

can cause permanent damage to the ABL1500Z.

www.aerotech.com Chapter 2 17

Mechanical Specifications and Installation ABL1500Z Hardware Manual

Figure 2-1: Lifting Features and Shipping Clamps

N O T E : After removing the lifting features or shipping brackets, retain them for future use. Do not

transport or ship the ABL1500Z without the lifting features or shipping brackets attached.

18 Chapter 2 www.aerotech.com

ABL1500Z Hardware Manual Mechanical Specifications and Installation

2.2. Dimensions

Figure 2-2: ABL1500Z Dimensions

www.aerotech.com Chapter 2 19

Mechanical Specifications and Installation ABL1500Z Hardware Manual

2.3. Securing the Stage to the Mounting Surface

The mounting surface must be flat and have adequate stiffness in order to achieve the maximum

performance from the ABL1500Z stage. When it is mounted to a non-flat surface, the stage can be distorted

as the mounting screws are tightened. This distortion will decrease overall accuracy. Adjustments to the

mounting surface must be done before the stage is secured.

W A R N I N G : Make sure that all moving parts are secure before moving the ABL1500Z.

Unsecured moving parts may shift and cause bodily injury.

D A N G E R : Strong rare-earth magnets are present in the linear motor magnet track. Loose

metal objects (tools, watches, keys, etc.) may cause personal injury and/or damage to the

equipment.

W A R N I N G : The ABL1500Z must be mounted securely. Improper mounting can result in

injury and damage to the equipment.

N O T E : To maintain accuracy, the mounting surface must be flat to within 2.5 µm.

N O T E : The stage base (or Z-Axis angle bracket) is precision machined and verified for flatness prior to

stage assembly at the factory. If machining is required to achieve the desired flatness, it should be

performed on the mounting surface rather than the stage base. Shimming should be avoided if possible. If

shimming is required, it should be minimized to improve the rigidity of the system.

Procedure for ABL1500Z mounting:

W A R N I N G : Do not attempt to move the carriage of the ABL1500Z until the air supply,

detailed in Section 1.4., has been installed. Moving the stage table without air supplied can

cause permanent damage to the stage.

1. Prepare the mounting surface and bottom mounting pads of the angle bracket with precision flatstones

to remove any burrs or high spots.

2. Clean the mounting surface and bottom of the angle bracket with the appropriate cleaners (acetone or

isopropyl alcohol for the angle bracket).

3. Place the stage on the mounting surface

4. Tighten the four mounting screws (Figure Figure 2-3). The typical torque value for M6 socket head cap

screws is 7 N-m.

5. Remove the lifting bracket from the back of the stage assembly (if shipped as a single axis). The lifting

bracket is mounted to the stage with M8-1.25x20mm socket head cap screws.

20 Chapter 2 www.aerotech.com

Table of contents

Other Aerotech Lifting System manuals