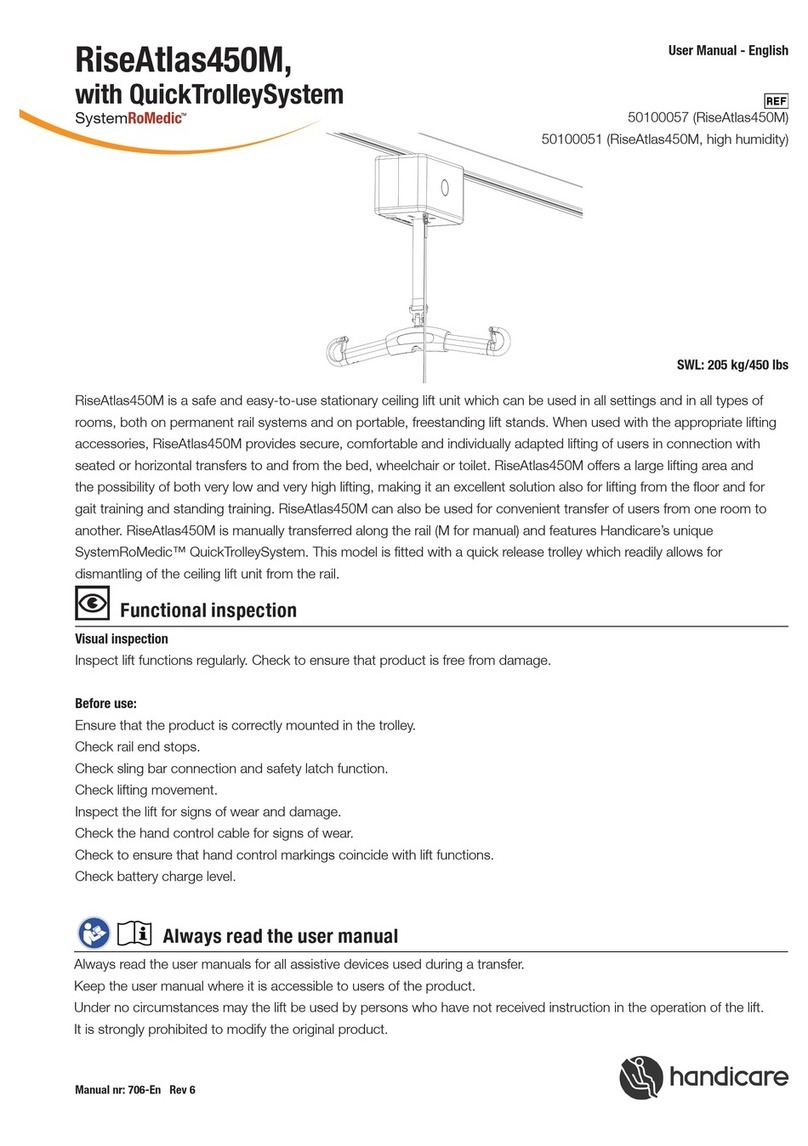

Handling and Storage

IMPORTANT: It is the responsibility of the customer to safely and carefully lift and

move the stage.

lBe careful when you move or transport the stage.

lRetain the shipping materials for future use.

lTransport or store the stage in its protective packaging.

WARNING: Electrostatic Discharge (ESD) Sensitive Components!

Wear an ESDwrist strap when you handle, install, or do service to the system assembly.

You could damage the power supply or drives if you fail to observe the correct

ESDpractices.

Inspect the shipping container for any evidence of shipping damage. If any damage exists, notify the

shipping carrier immediately.

Remove the packing list from the shipping container. Make sure that all the items specified on the

packing list are contained within the package.

The documentation for the stage is on the included installation device. The documents include

manuals, interconnection drawings, and other documentation pertaining to the system. Save this

information for future reference.

Each stage has a label listing the system part number and serial number. These numbers contain

information necessary for maintenance or system hardware and software updates. Locate this label

and record the information for later reference.

Unpacking and Handling

It is the responsibility of the customer to safely and carefully lift and move the stage.

IMPORTANT: All electronic equipment and instrumentation is wrapped in antistatic

material and packaged with desiccant. Ensure that the antistatic material is not

damaged during unpacking.

DANGER:Lifting Hazard! Use care when you move the ANT130LZ or you could

negatively affect the performance of it.

lUse the correct lifting techniques, mechanical assistance, or additional help to lift or

move this product.

lDo not use the cables or the connectors to lift or move this product.

lMake sure that all moving parts are secure before you move the stage. Unsecured

moving parts could shift and cause injury or damage to the equipment.

lIf the stage is heavy, a single person lift could cause injury. Use assistance when you

lift or move it.

oRefer to Section 2.1. Dimensions for dimensions

oRefer to Section 1.3. Basic Specificationsfor weight specifications.

Carefully remove the stagefrom its protective shipping container.

lLift this product only by the vertical mounting bracket.

To access the vertical mounting bracket, you must first remove the pneumatic cover. Refer to Fig-

ure 3.

lFor multi-axis assemblies, always lift the system by the lower axis.

lUse a cart, dolly, or similar device to move the stage to a new location.

ANT130LZ Hardware Manual

14 www.aerotech.com