8

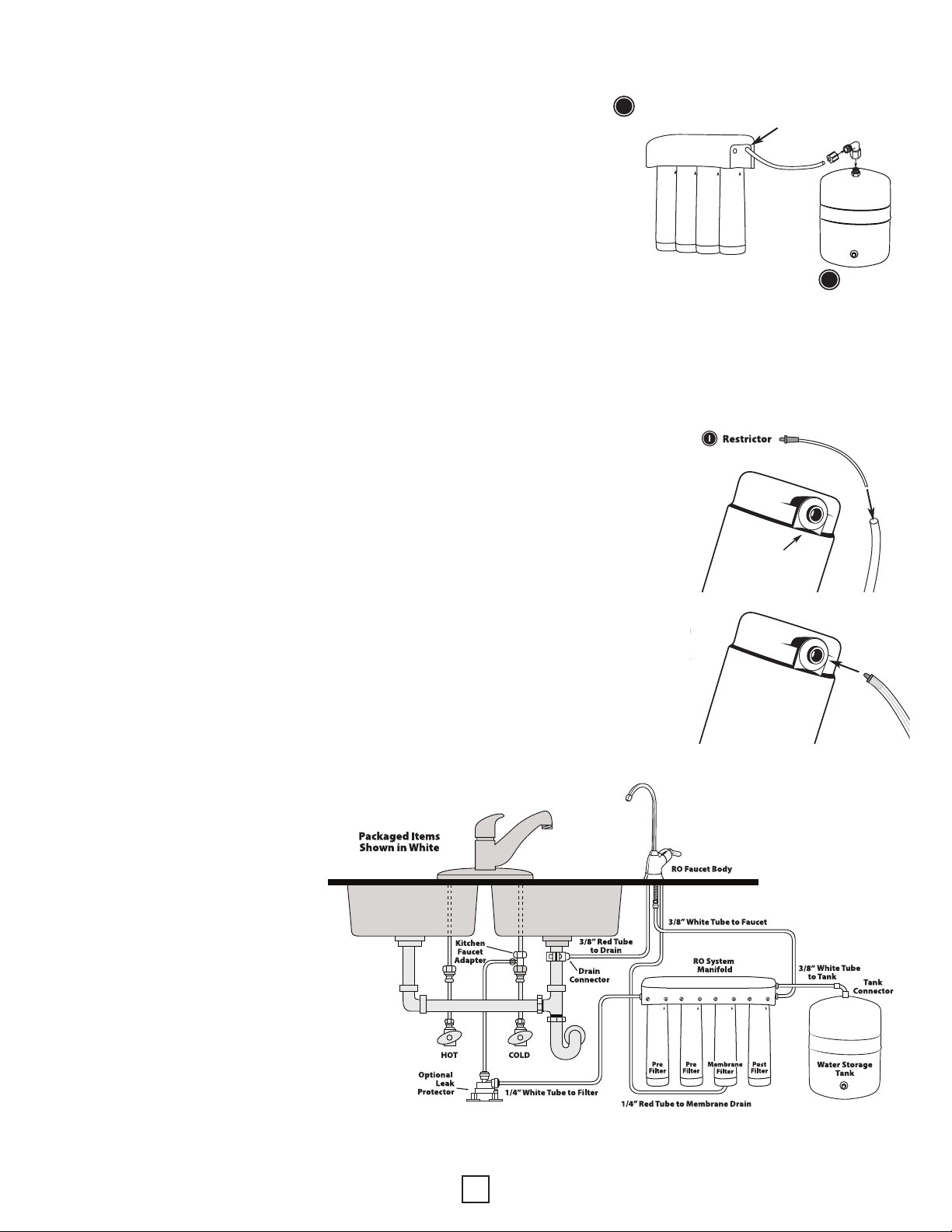

Kitchen Faucet

Adapter

F

Inlet Water

Tube Connection

Manifold Outlet

for Faucet

A

RO System

Manifold

Kitchen Faucet

Adapter

F

Inlet Water

Tube Connection

Manifold Outlet

for Faucet

A

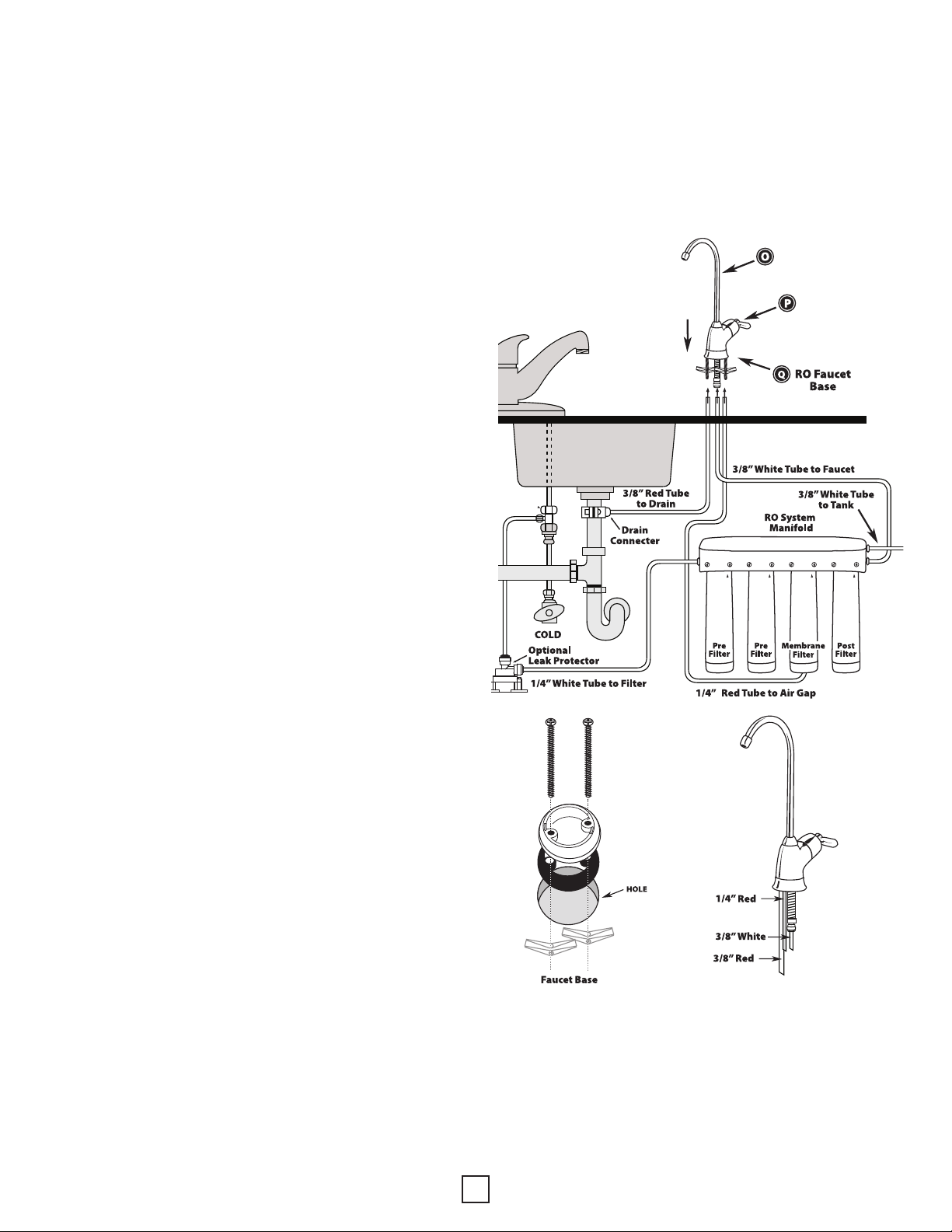

STEP SIX – CONNECT TUBING

Notice: For servicing, tubing lengths should allow

for removal of assembly from mount screws.

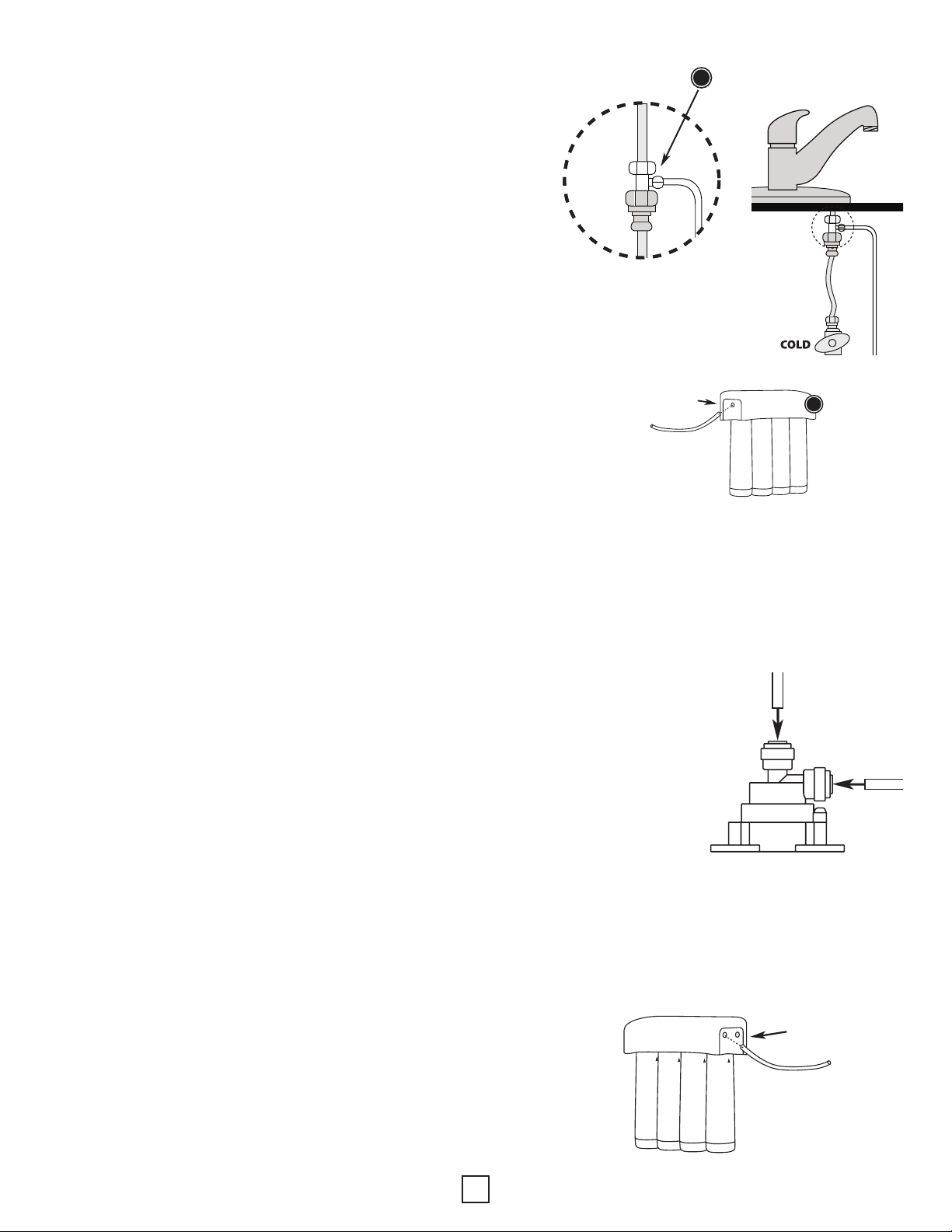

INSTALL TUBING FOR WATER SUPPLY LINE FROM

KITCHEN FAUCET ADAPTOR TO MANIFOLD INLET.

Notice: Do not bend or crimp tubing during this step.

1. Identify length of 1/4” white tubing necessary to

connect (A) manifold “INLET” to (F) kitchen faucet adaptor.

Allow sufcient tubing to prevent line kinking. Do not

discard remaining tubing.

2. With utility knife, cut the 1/4” white tubing

squarely to desired length.

3. With water, wet one end of tubing and push into the

kitchen faucet adaptor approximately 5/8” until it stops.

4. Wet other end of tubing and push into the manifold “INLET”

approximately 5/8” until it stops.

Notice: It is not necessary to remove tubing for routine maintenance and lter

exchanges, however, it may easily be disconnected if necessary. To disconnect,

turn off water supply to system and press in white collar around tting while

pulling tubing out with other hand.

INSTALL OPTIONAL LEAK PROTECTOR – PART NUMBER 49451

1. Turn off the water supply to the ltration system at the cold water source valve.

2. The leak protector should be mounted at in the lowest ground point

near the ltration system so in the event a leak occurs, the water will ow

in the direction of the valve.

3. Clean the designated installation area with rubbing alcohol.

4. Peel the red backing tape from the two mounting feet on the base of the

leak protector valve and press down rmly over the chosen install area.

You may also mount the valve using the screws included in the kit.

5. Cut the system’s water supply tube to plumb in the valve. Connect the

tube from the water source valve to the horizontal tting on the leak

protector valve labeled “in” by pushing the tubing in rmly until fully seated.

6. Connect the tube leading from the ltration system to the vertical tting on the

leak protector valve labeled “out” by pushing the tubing in rmly until fully seated.

7. Turn on the water supply to the ltration unit and check for leaks.

INSTALL TUBING FOR WATER SUPPLY LINE FROM MANIFOLD

OUTLET TO FAUCET.

1. Locate 3/8” white tubing already attached to faucet stem during Step 5 on page 6.

2. Identify length of tubing necessary to connect to manifold outlet labeled “FAUCET.”

3. Cut tubing squarely with utility knife. Do not discard remaining tubing.

4. With water, wet one end of tubing and push into manifold outlet labeled “FAUCET”

approximately 5/8” until it stops.

RO System

Manifold

Kitchen Faucet

Adapter

FInlet Water

Tube Connection

Manifold Outlet

for Faucet

A

from cold

water source

valve

from

Filtration

System

Optional Leak Protector