PEZ-52-65-80-100 BA-vers.1.3 gb.15.10.14.doc Seite 5

1.0.0 EC Declaration for Incorporation (Original documentation)

1.1.0 According to 2006/42/EC dated 09. June 2006, Appendix II B VI for

Incorporation of partly completed machinery.

The manufacturer: Afag Automation AG, Fiechtenstrasse 32, CH-4950 Huttwil,

Tel. +41 62 959 87 02, www.afag.com

As manufacturer of the partly completed machine we declare that:

The specified machine corresponds to the listed essential requirements of the

directive 2006/42/EG, wehere applicable the other directives and standards listed

below.

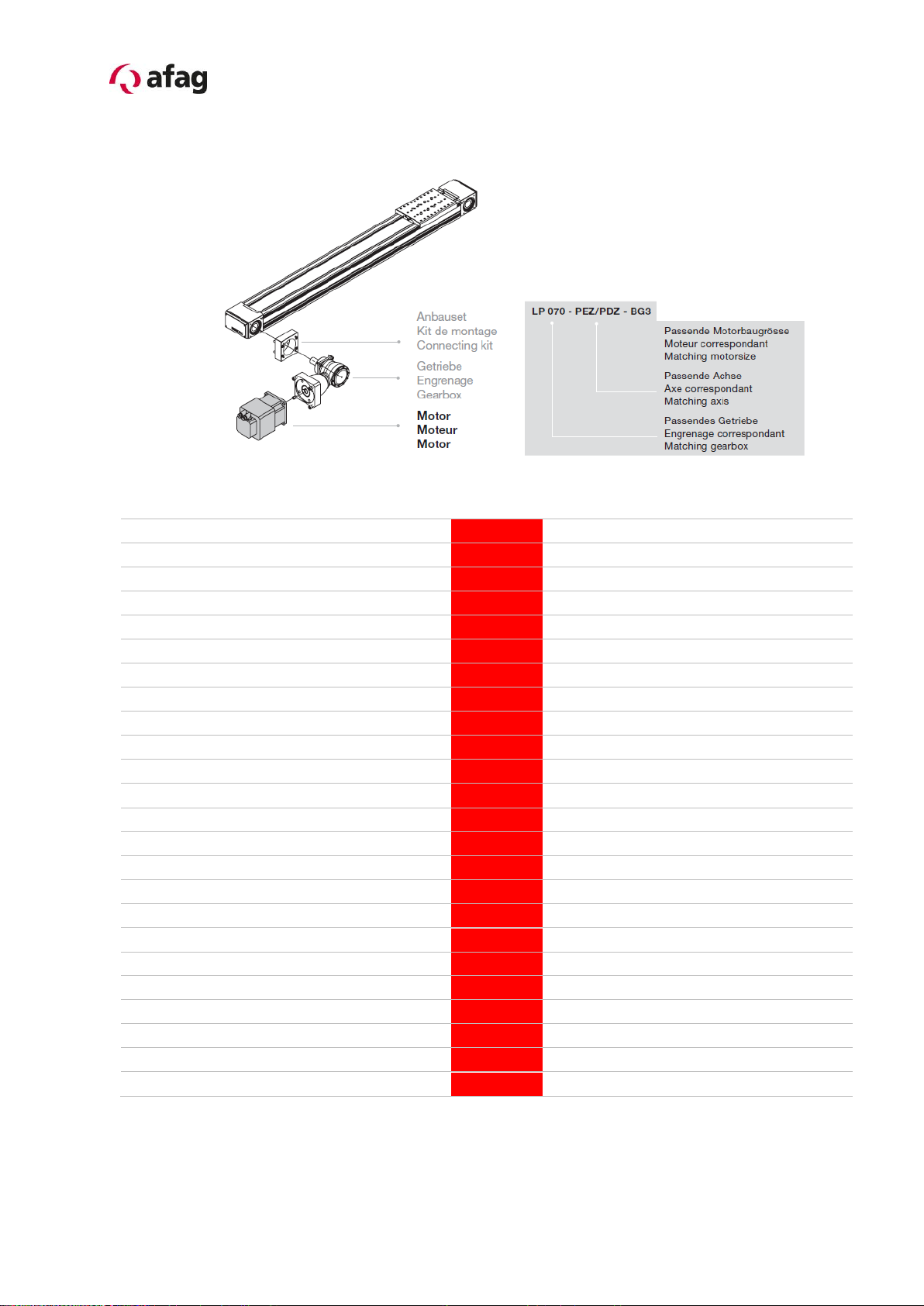

Producte name: Gantry axis PEZ (electrical)

Types: PEZ-52-65-80-100

Sequential series:

-Machinery Directive 2006/42/EC

-Low voltage Directive 2006/42/EG

-The relevant technical documentation is compiled in accordance with part B of

Annex VI

-The relevant technical documentation in accordance with part B of Annex VI

will be transmitted in response to a reasonable request by the national

authorities in printed from or in electronic from (pdf).

Increase of the harmonized

standards applied:

EN 349; EN ISO 12100-1; EN 121000-2; EN ISO

14121-1; EN 60204-1: 2006

Applied and fulfilled essential requirements:

1.1; 1.1.1; 1.1.2; 1.2; 1.2.1; 1.2.3; 1.2.4.4; 1.2.5; 1.3; 1.3.3; 1.3.5; 1.3.6; 1.3.7;

1.3.8.1; 1.3.8.2; 1.3.9; 1.4; 1.4.1; 1.5; 1.5.1; 1.6; 1.6.1; 1.6.3; 1.6.4; 1.7; 1.7.1; 1.7.4.;

1.7.4.1; 1.7.4.2; 1.7.4.3; 3.3.5; 3.4.1

This partly completed machinery must not be put into service until the final machinery

into which it is to be incorporated has been declared in conformity with the provisions

of this Directive 2006/42/EC, where appropriate.

Name and address of the person authorised to compile the relevant technical documentation:

Lanz Beat, PM & Marketing-Services, Afag Automation AG

Place/Date: Huttwil, 15.10.2014

Markus Werro

Managing Director

Afag Automation AG

Siegfried Egli

Head of HT

Afag Automation AG

Hier wird bei Auslieferung des

Geräts die aktuelle Seriennummer

eingeklebt.