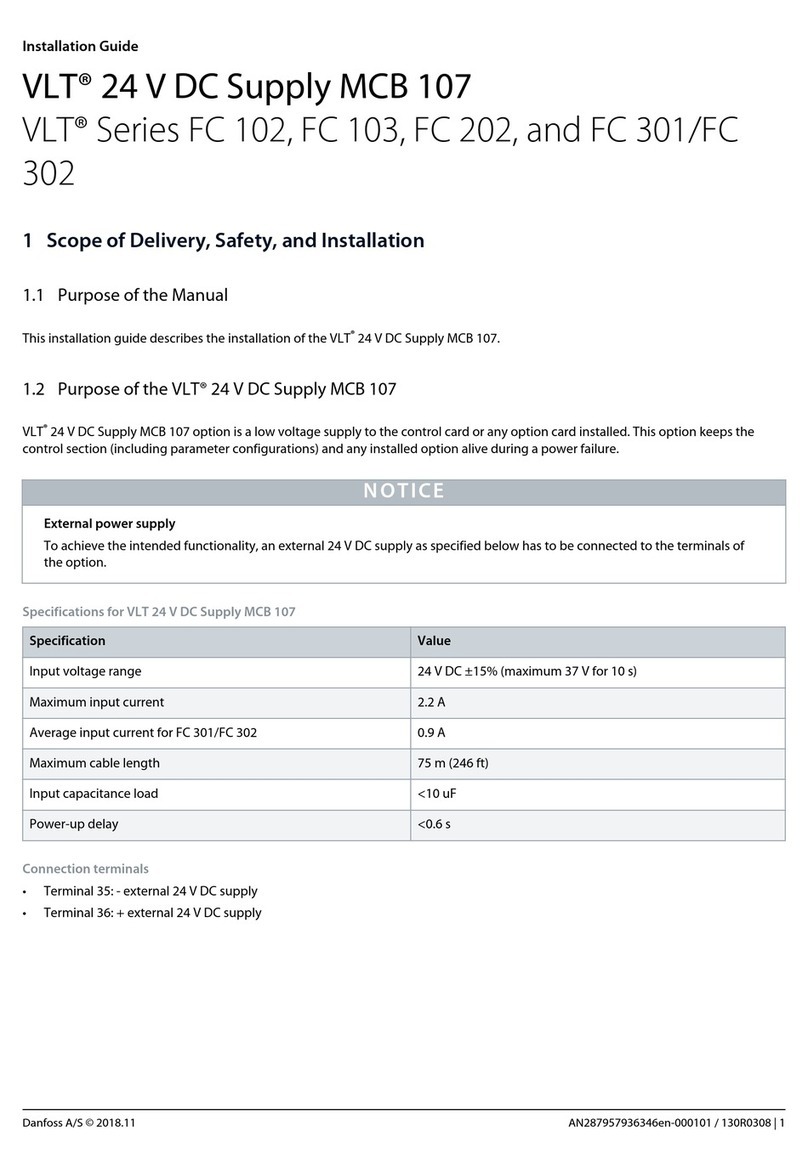

MG.28.F1.02 - VLT is a registered Danfoss trademark 195R0050

➎

➍

➊

➋

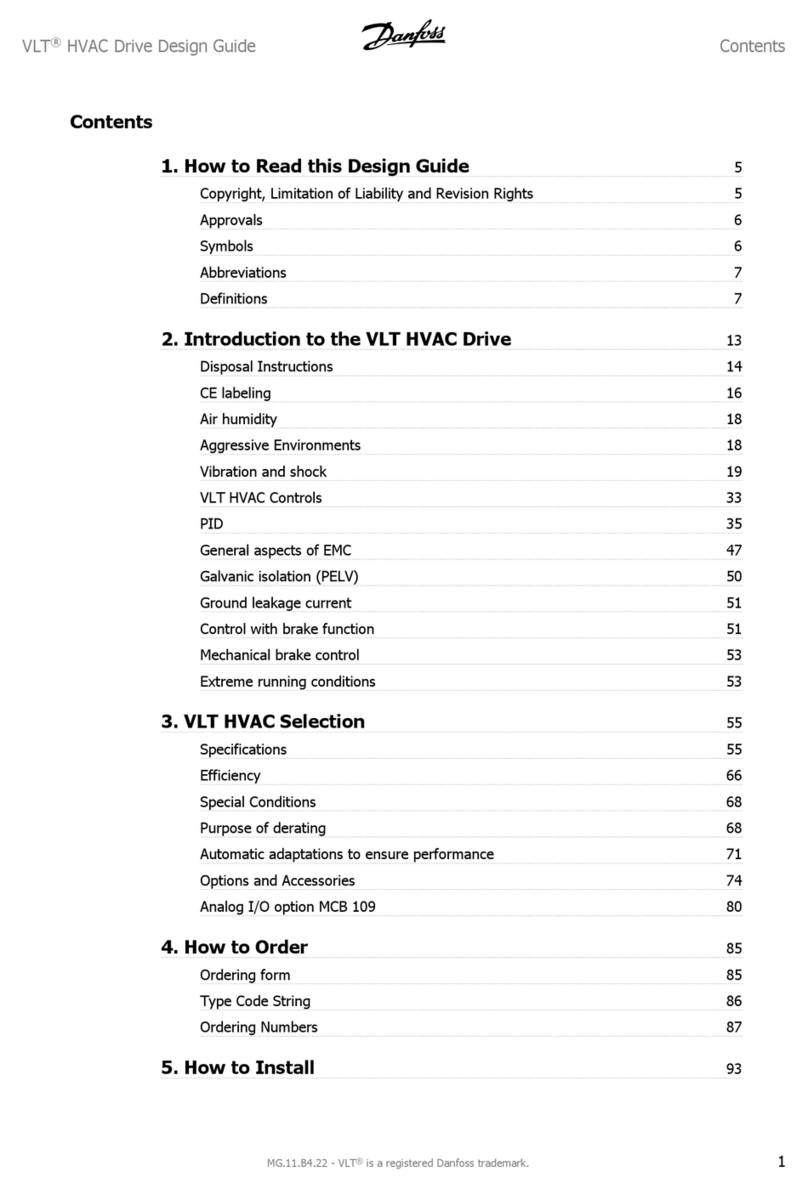

Fig. 3

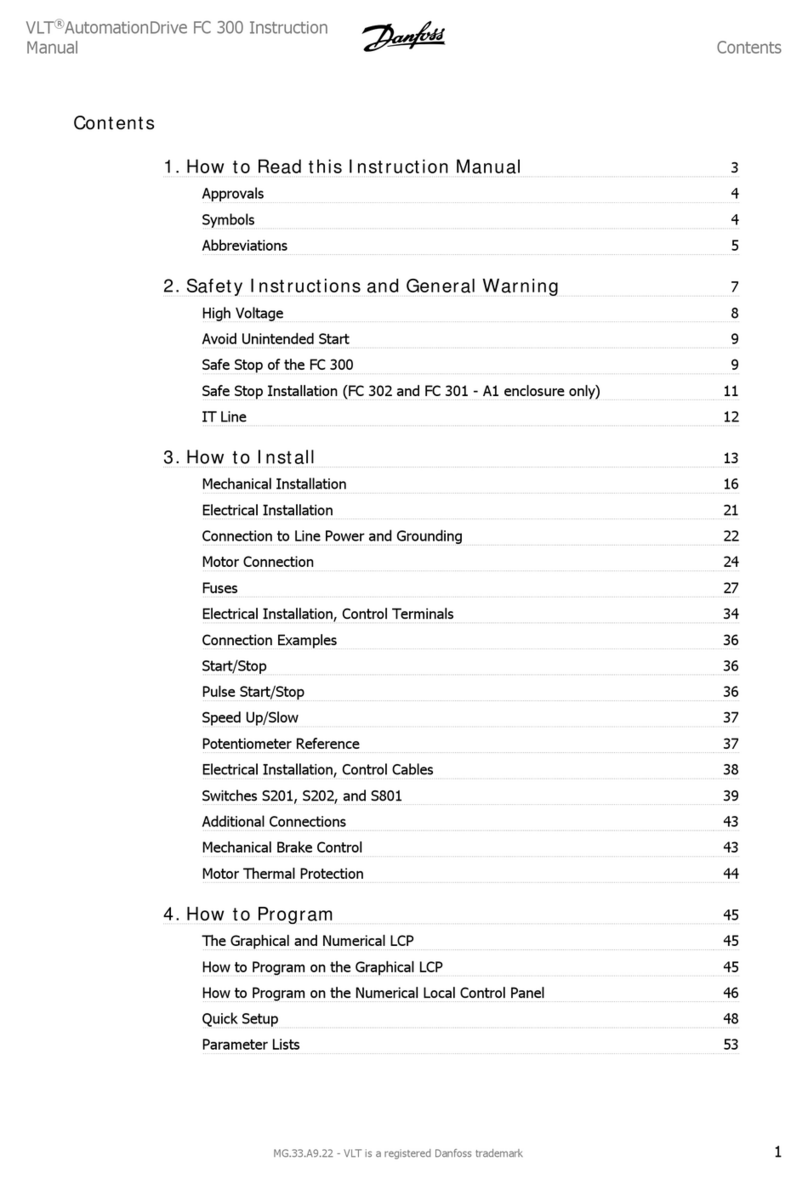

Using this Quick Setup, you can carry out quick

and EMC-correct installation of the frequency

converter (Fig. 1) in five steps. (Fig. 1: *= Start/

stop). The Operating Instructions, which are also

enclosed, give other examples of installation and

describe all functions in detail.

Read the safety instructions on this page before

installing the unit.

Mechanical installationMechanical installation

Mechanical installationMechanical installation

Mechanical installation

VLT 2800 frequency converters allow side-by-

side installation on a wall. Because of the need for

cooling, there must be 10 cm free air passage

above and below the frequency converter.

Drill holes in accordance with the measurements

given in fig. 2. Please note the difference in unit

voltages.

Retighten all four screws.

Fit the decoupling plate to the power cables and

the earth screw (terminal 95).

VLVL

VLVL

VLTT

TT

T®®

®®

® 2800 2800

2800 2800

2800 Quick Setup Quick Setup

Quick Setup Quick Setup

Quick Setup

Fig. 2

ProgrammingProgramming

ProgrammingProgramming

Programming

Carry out programming on the control panel.

Press the [QUICK MENU] key to enter the Quick

menu.

In this menu, parameters can be selected by

means of the [+] and [-] keys. The parameter

values can be changed by pressing [CHANGE

DATA].

Changes are programmed using the [+] and [-]

keys.

Finish the change of a parameter setting by

pressing [CHANGE DATA].

A change of parameter values is saved automa-

tically after a mains failure.

If the display shows three dots at the right, the

parameter value has more than three digits. In

order to see the value, activate [CHANGE DATA].

Press [QUICK MENU]:

Set the motor parameters that are on theSet the motor parameters that are on the

Set the motor parameters that are on theSet the motor parameters that are on the

Set the motor parameters that are on the

nameplate of the motor:nameplate of the motor:

nameplate of the motor:nameplate of the motor:

nameplate of the motor:

Motor power [kW] parameter 102

Motor voltage [V] parameter 103

Motor frequency [Hz] parameter 104

Motor current [A] parameter 105

Rated motor speed parameter 106

Activate AMTActivate AMT

Activate AMTActivate AMT

Activate AMT

::

::

:

Automatic motor tuning parameter 107

Set reference rangeSet reference range

Set reference rangeSet reference range

Set reference range

Min. reference, RefMIN parameter 204

Max. reference, RefMAX parameter 205

Set ramp timesSet ramp times

Set ramp timesSet ramp times

Set ramp times

Ramp-up time [s] Parameter 207

Ramp-down time [s] Parameter 208

Electrical installation, powerElectrical installation, power

Electrical installation, powerElectrical installation, power

Electrical installation, power

Please note that the power terminals can be

removed.

Connect mains to the mains terminals of the

frequency converter, i.e. 91, 92, 93 and the earth

connection to terminal 95 (Fig. 3).

Fit a screened/armoured cable from the motor to

the motor terminals of the frequency converter,

i.e. U, V, W (Fig. 3). The screen ends in a screen

connector.

➌

Fig. 1

Fig. 4

Electrical installation, control cablesElectrical installation, control cables

Electrical installation, control cablesElectrical installation, control cables

Electrical installation, control cables

Remove the front cover underneath the control

panel. Place a jumper between terminals 12 and

27. (Fig. 4).

In parameter 002 Local/remote control, the

frequency converter mode can be selected as

Remote operation [0], i.e. via the control

terminals, or Local [1], i.e. via the control unit.

Set the control location toSet the control location to

Set the control location toSet the control location to

Set the control location to LocalLocal

LocalLocal

Local [1][1]

[1][1]

[1]..

..

.

Local/remote operation = Local [1] Par. 002

Set the motor speed by adjusting theSet the motor speed by adjusting the

Set the motor speed by adjusting theSet the motor speed by adjusting the

Set the motor speed by adjusting the LocalLocal

LocalLocal

Local

referencereference

referencereference

reference

Local reference Parameter 003

Motor startMotor start

Motor startMotor start

Motor start

Press [Start] to start the motor. Set the motor

speed by adjusting parameter 003 Local

reference.

Check whether the direction of rotation of the

motor shaft is clockwise. If not, exchange any

two phases on the motor cable.

Press [STOP/RESET] to stop the motor.

Press [QUICK MENU] to return to display

mode.

(QUICK MENU] + [+] keys must be pressed

simultaneously to give access to all

parameters.

Safety regulationsSafety regulations

Safety regulationsSafety regulations

Safety regulations

The voltage of the frequency converter can be

fatal whenever it is connected to mains. Incorrect

installation of the motor or the frequency

converter may lead to damage to the equipment,

serious personal injury or death.

Consequently, the provisions of this Quick Setup,

as well as national and local rules and safety

regulations, must be complied with.

Touching the electrical parts may be fatal, even

after the equipment has been disconnected from

mains: wait at least 4 min.

1. The mains supply to the frequency

converter must be disconnected if repair work is

to be carried out.

2. The [STOP/RESET] key on the control

panel of the frequency converter does not

disconnect the mains supply and is thus not to

be used as a safety switch.

3. Correct protective earthing of the unit must

be established, the user must be protected

against supply voltage, and the motor must be

protected against overload in accordance with

applicable national and local regulations.

4. The earth leakage current is higher than 3.5

mA.

5. Protection against motor overload is not

included in the factory setting. If this function is

required, set parameter 128 Motor thermal

protection to data value ETR Trip or ETR

Warning.

6. Check that the mains supply has been

disconnected before removing the motor and

mains plugs.

Warning against unintended startWarning against unintended start

Warning against unintended startWarning against unintended start

Warning against unintended start

1. The motor can be brought to a stop by

means of digital commands, bus commands,

references or local stop, while the frequency

converter is connected to mains. If personal

safety considerations make it necessary to

ensure that no unintended start occurs, these

stops are not sufficient.

2. While parameters are being programmed,

the motor may start. Consequently, the stop key

[STOP/RESET] must always be activated,

following which data can be modified.

3. A motor that has been stopped may start if

faults occur in the electronics of the frequency

converter, or if a temporary overload, a fault in

the supply mains or a fault in the motor

connection ceases.

VLT 2840 200-240 V

VLT 2855-2875 380-480 V

*