CHAPTER 2: Preventative Maintenance

2.1 PREVENTATIVE MAINTENANCE

Preventative maintenance is the key to smoothly operating equipment, as well as keeping the user’s liability to

a minimum. Equipment needs to be inspected at regular intervals. Defective components must be replaced

immediately. Improperly working equipment must be kept out of use until it is repaired. Ensure that any

person(s) making adjustments or performing maintenance or repair of any kind is qualified to do so.

EVERY DAY (DAILY)

Clean and inspect, following these steps:

•Turn off the treadmill with the ON / OFF switch, then unplug the power cord at the wall outlet.

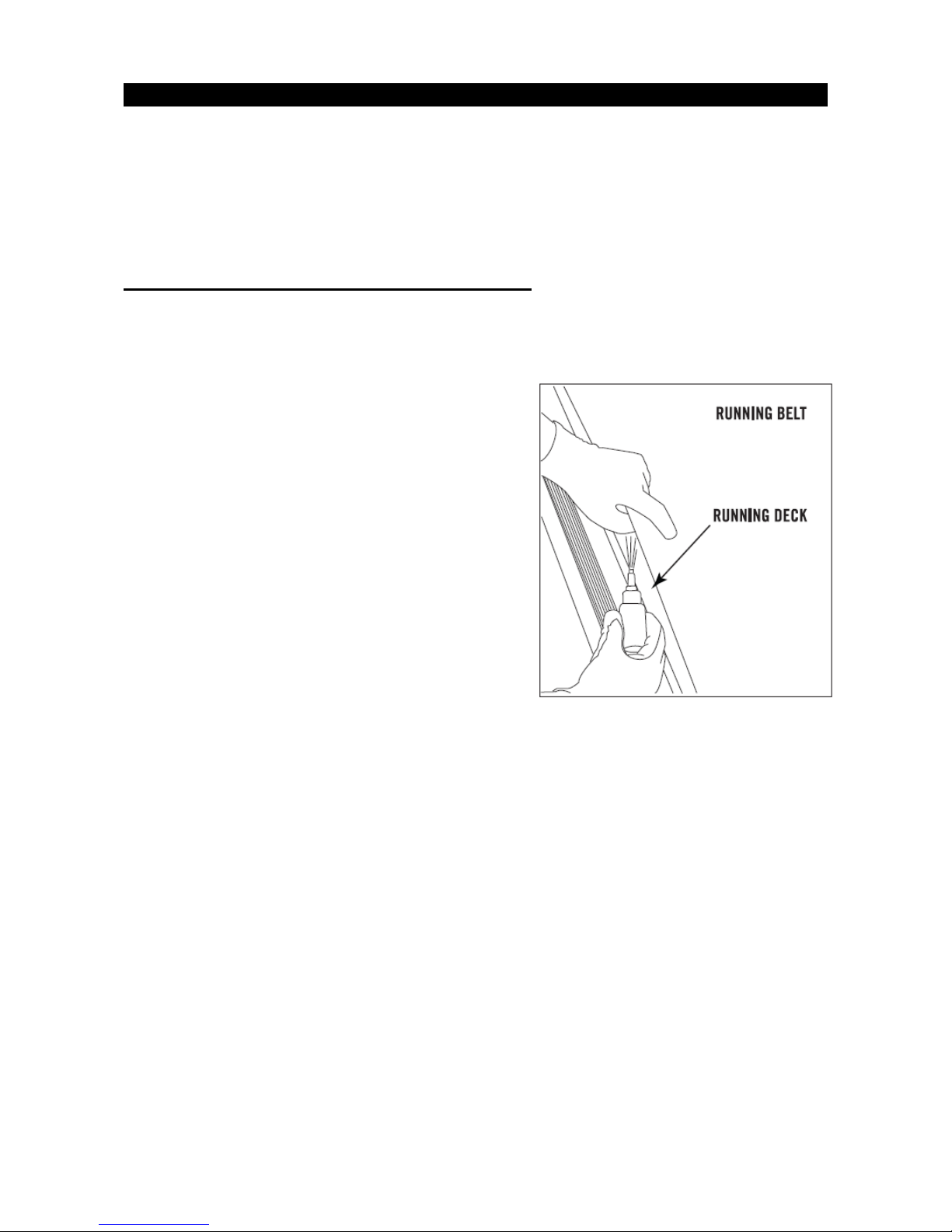

•Wipe down the running belt, deck, motor cover, and console casing with a damp cloth. Never use

solvents, as they can cause damage to the treadmill.

•Inspect the power cord. If the power cord is damaged, stop using and contact Customer Technical

Support.

• Make sure the power cord is not underneath the treadmill or in any other area where it can become

pinched or cut.

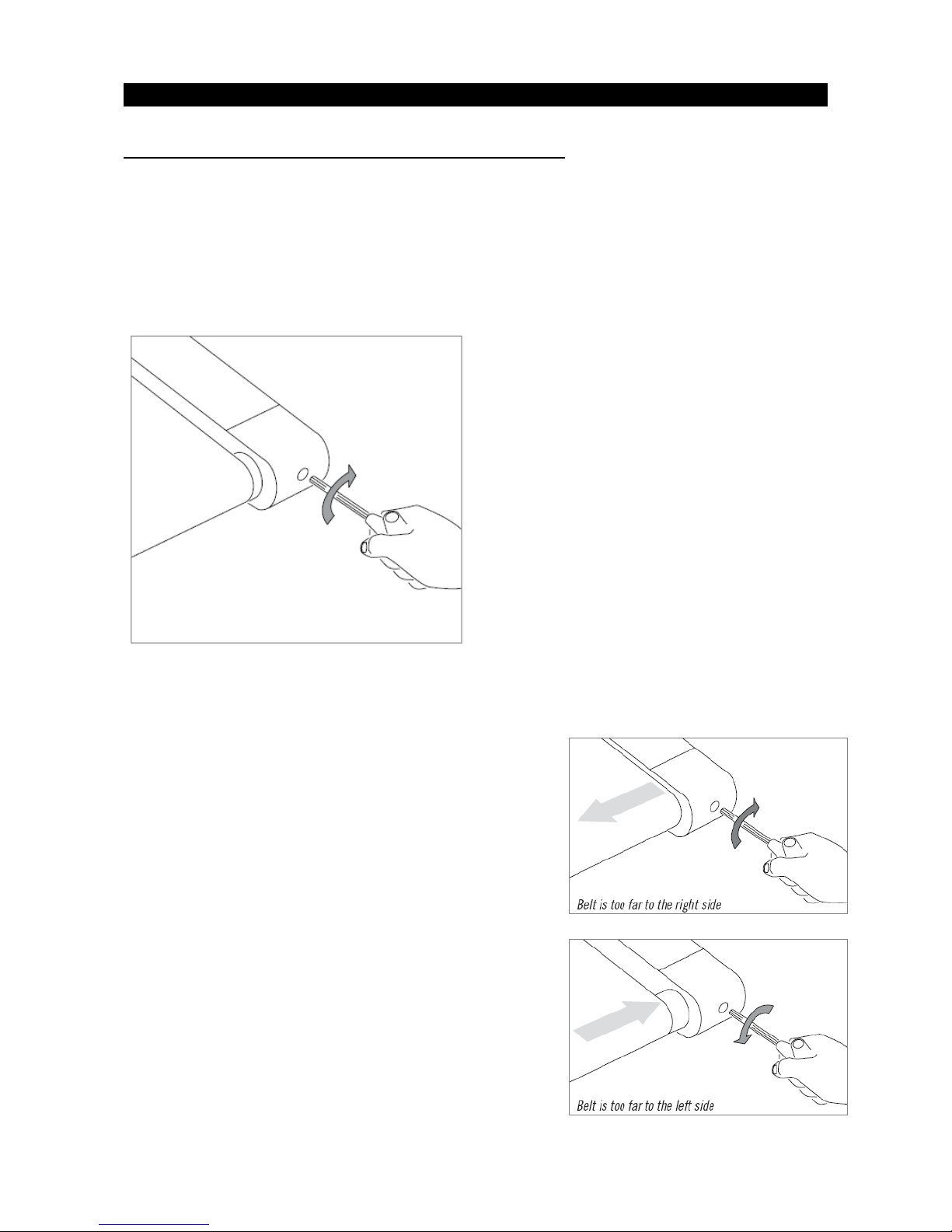

• Check the tension and alignment of the running belt. Make sure that the treadmill belt will not damage any

other components on the treadmill by being misaligned.

•If any labels are damaged or illegible, contact Customer Technical Support for replacements.

EVERY WEEK (WEEKLY)

Clean underneath the treadmill following these steps:

•Turn off the treadmill with the ON / OFF switch, then unplug the power cord at the wall outlet.

•Fold the treadmill into the upright position, making sure that the lock latch is secured.

•Move the treadmill to a remote location.

•Wipe or vacuum any dust particles or other objects that may have accumulated underneath the treadmill.

•Return the treadmill to its previous position.

EVERY MONTH - IMPORTANT!

•Turn off the treadmill with the ON / OFF switch, then unplug the power cord at the wall outlet.

•Inspect all assembly bolts of the machine for proper tightness.

•Remove the motor cover. Wait for ALL display screens to be off.

•Clean the motor and lower board area to eliminate any lint or dust particles that may have accumulated.