Afriso EURO-INDEX RG 210 User manual

Mess-, Regel- und

Überwachungsgeräte

für Haustechnik,

Industrie und Umweltschutz

Lindenstraße 20

DE-74363 Güglingen

Telefon: +49(0)7135-102-0

Service: +49(0)7135-102-211

Telefax: +49(0)7135-102-14

7

E-Mail: info@afriso.de

Internet: www.afriso.de

Read manual before use!

Observe all safety information!

Keep manual for future use!

01.2009 0

854.001.0149

Instruction Manual

Level Controller

RG 210

# 53206

2RG 210

Contents

1 This instruction manual ............................................................................................3

1.1 Structure of warning .....................................................................................3

1.2 Explanation of symbols and typeface...........................................................3

2 Safety.......................................................................................................................4

2.1 Intended use .................................................................................................4

2.2 Predictable incorrect application ..................................................................4

2.3 Safe handling................................................................................................5

2.4 Staff qualification ..........................................................................................5

2.5 Modifications to the product..........................................................................5

2.6 Use of spare parts and accessories .............................................................6

2.7 Liability information.......................................................................................6

3 Product description ..................................................................................................6

3.1 Operating modes ..........................................................................................7

3.2 Application examples....................................................................................9

4 Specifications.........................................................................................................10

4.1 Approvals, tests and conformities ..............................................................12

5 Transportation and storage....................................................................................12

6 Installation and commissioning..............................................................................13

6.1 Installing the device ....................................................................................13

6.2 Electrical connection...................................................................................14

6.3 Selecting the operating mode.....................................................................16

6.4 Commissioning the device..........................................................................16

6.5 Function test ...............................................................................................17

7 Operation ...............................................................................................................17

8 Maintenance ..........................................................................................................17

8.1 Maintenance intervals.................................................................................17

8.2 Maintenance activities ................................................................................18

9 Troubleshooting .....................................................................................................18

10 Shutting down and disposal...................................................................................19

11 Spare parts and accessories .................................................................................19

12 Warranty ................................................................................................................20

13 Copyright................................................................................................................20

14 Customer satisfaction ............................................................................................20

15 Addresses ..............................................................................................................20

This instruction manual

RG 210 3

1 This instruction manual

This instruction manual is part of the product.

X Read this manual before using the product.

X Keep this manual during the entire service life of the product

and always have it readily available for reference.

X Always hand this manual over to future owners or users of the

product.

1.1 Structure of warning

WARNING TERM

Type and source of the danger is shown here.

X Precautions to take in order to avoid the danger are shown

here.

There are three different levels of warnings:

Warning term Meaning

DANGER Immediately imminent danger!

Failure to observe the information will result in

death or serious injuries.

WARNING Possibly imminent danger!

Failure to observe the information may result in

death or serious injuries.

CAUTION Dangerous situation!

Failure to observe the information may result in

minor or serious injuries as well as damage to

property.

1.2 Explanation of symbols and typeface

Symbol Meaning

; Prerequisite for an activity

X Activity consisting of a single step

1. Activity consisting of several steps

ª Result of an activity

• Bulleted list

Text Indication on a display

Highlighting Highlighting

Safety

4RG 210

2 Safety

2.1 Intended use

The RG 210 level controller may only be used as a level switch, as

level control for filling or as level control for emptying for liquids. The

RG 210 level controller detects minimum or maximum levels and

switches pumps or valves to control levels of liquids.

The RG 210 level controller consists of a control unit and one PTC

thermistor probe (level switch) or two PTC thermistor probes (level

control for filling and emptying). The control unit may only be used

with PTC thermistor probes type 937 and type 150.

The RG 210 level controller may only be used for the following

liquids:

With the type 937 PTC thermistor probe only for:

• Fuel oil EL, L or M

With the type 150 PTC thermistor probe only for:

• Water

• Fuel oil EL, L or M

• Diesel fuel or low-viscosity lubricants group AIII and danger

class AIII

• Motor oils, gearbox oils and hydraulic oils

• Vegetable oils and transformer oils

• Antifreeze agents

• Oil-water mixtures, emulsion

and comparable liquids (not AI, AII !) with equivalent heat conductiv-

ity if these liquids do not attack the following wetted parts:

• PTC thermistor probe: stainless steel

• Plastic: PA6 (Furkamid B SK 1)

• Sealing material: 3M Scotch Cast No 815 perm. elast. 2 comp.

• Cable Oilflex 100: resistant to acids, lye and oils and not agglu-

tinating or coking

Any use other than the use explicitly stated in this instruction manual

is not permitted.

2.2 Predictable incorrect application

The RG 210 level controller must never be used in the following:

• Use as an overfill alarm system according to TRbF

Safety

RG 210 5

• Hazardous areas (ex)

If the device is operated in hazardous areas, sparks may cause

deflagrations, fires or explosions

2.3 Safe handling

This product represents state-of-the-art technology and is manufac-

tured in accordance with the pertinent safety regulations. Each unit is

subjected to a function and safety test prior to despatch.

X Operate the product only when it is in perfect condition. Always

observe the instruction manual, all pertinent local and national

directives and guidelines as well as health and safety regula-

tions and directives regarding the prevention of accidents.

WARNING Severe burns or death due to mains voltage in the control unit

(AC 230 V, 50 Hz).

X Do not expose the control unit to water.

X Interrupt the mains voltage supply before opening the control

unit or before performing maintenance and cleaning work and

make sure it cannot be switched on by accident.

X Do not tamper with the control unit in any way whatsoever.

WARNING Risk of burns and explosions due to hot probe tip (probe tip can

reach temperatures of up to 100 °C).

X Never touch the probe tip.

X The probe and the control unit must not be operated in hazard-

ous areas.

2.4 Staff qualification

The product may only be installed, commissioned, operated, main-

tained, shut down and disposed of by qualified, specially trained per-

sonnel.

Electrical work may only be carried out by qualified electricians in

accordance with local and national regulations.

2.5 Modifications to the product

Changes or modifications made to the product by unauthorised per-

sons may lead to malfunctions and are prohibited for safety reasons.

Product description

6RG 210

2.6 Use of spare parts and accessories

Use of unsuitable spare parts and accessories may cause damage

to the product.

X Use only the manufacturer’s genuine spare parts and accesso-

ries (refer to chapter 0, page 19).

2.7 Liability information

The manufacturer shall not be liable for direct or consequential dam-

age resulting from failure to observe the technical instructions, guide-

lines and recommendations.

The manufacturer and the sales company shall not be liable for costs

or damages incurred by the user or by third parties in the usage or

application of this device, in particular in case of improper use of the

device, misuse or malfunction of the connection, malfunction of the

device or of connected devices. The manufacturer or the sales com-

pany shall not be liable for damages resulting from any use other

than the use explicitly stated in this instruction manual.

The manufacturer shall not be liable for misprints.

3 Product description

Control unit

The control unit contains the following elements in an impact-resis-

tant plastic housing: Display elements and controls as well as all

electronic components for signal processing and conversion of the

probe signal into a digital output signal. The output signal is available

as a voltage-free relay contact (1 changeover contact).

RG 210 can be operated with the type 937 and type 150 PTC ther-

mistor probes. The PTC thermistor probes are not included with the

RG 210.

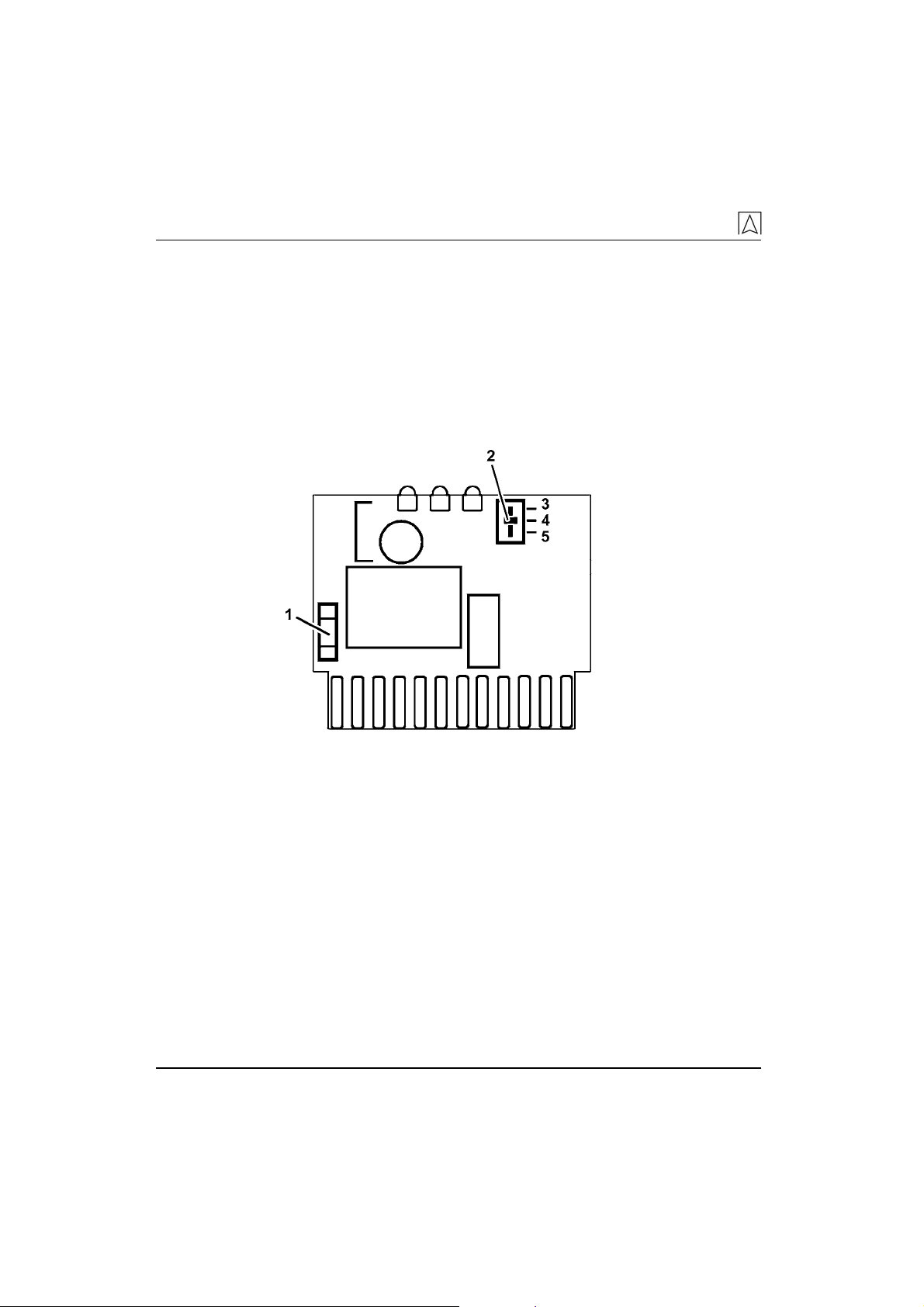

1Yellow LED for

probes

2Green LED for

release

3Base

4Upper part of

housing

Fig. 1: Control unit

Product description

RG 210 7

Probe

The control unit and the PTC thermistor probe are connected by

means of a signal cable. The tip of the probe is equipped with a PTC

thermistor. During operation, the PTC thermistor is heated and can

distinguish between gaseous and liquid media due to the different

heat dissipation.

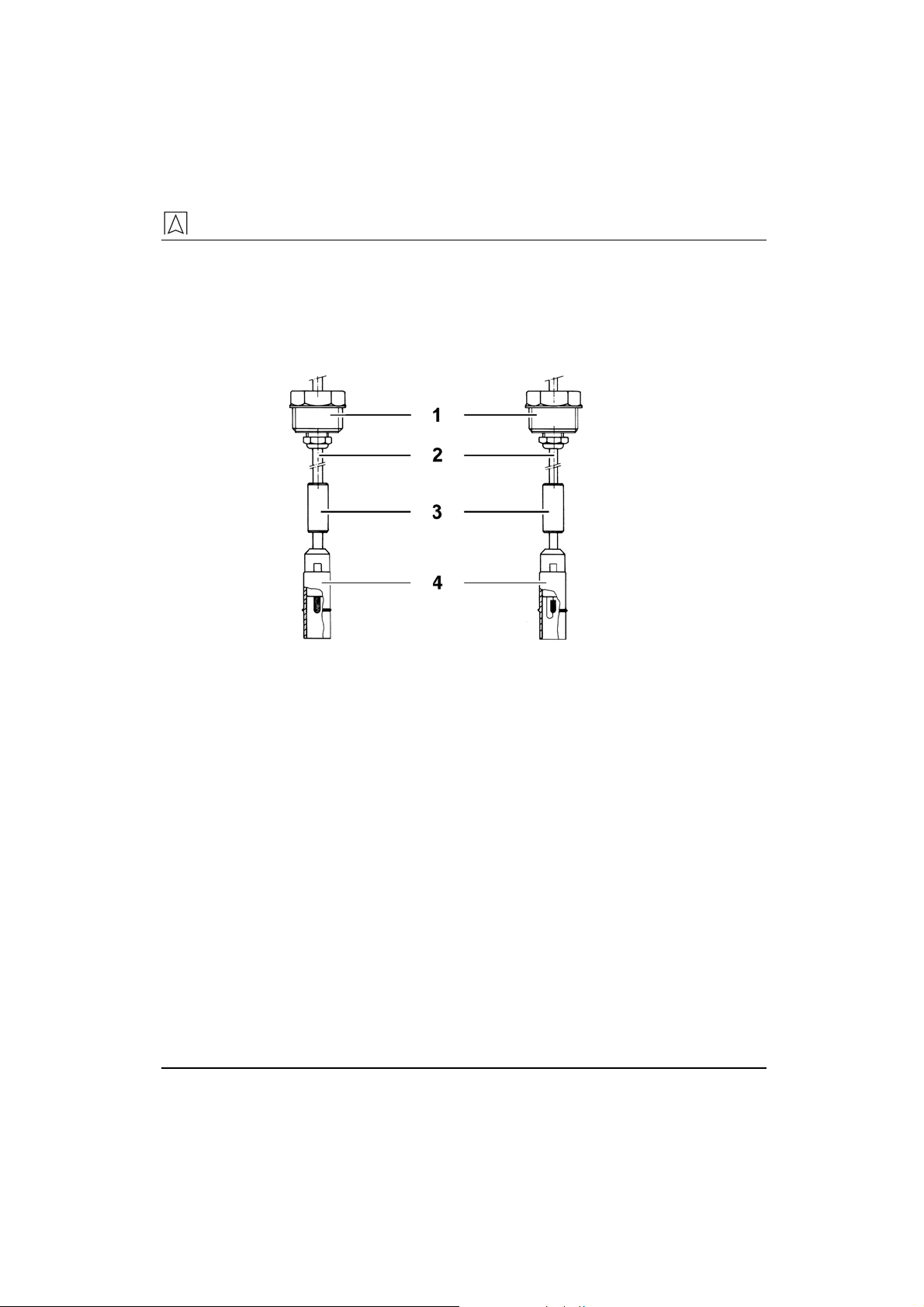

1Plastic screw

connector

2Probe cable

3Brass weight

4Protective sleeve

for PTC thermis-

tor

Fig. 2: Probe type 150 Fig. 3: Probe type 937

3.1 Operating modes

When the mains voltage is switched on, the connected PTC thermis-

tor heats up. Three different operating modes must be distinguished.

The various operating modes are set by means of a selector on the

printed circuit board.

Operating mode “Probe 1”: level switch

Only the signal received from probe 1 is processed. A second probe

may be connected, but it will not be considered.

If the PTC thermistor is exposed to air (i. e. not submerged in liquid)

once probe 1 is fully heated up, the yellow LED "Probe 1" goes out,

the green LED "Release" lights up and the output relay is energised.

If the PTC thermistor of probe 1 is submerged in liquid or if the heat-

up process of probe 1 is not yet finished or if probe 1 is not con-

nected or short-circuited, the yellow LED "Probe 1" lights up, the

green LED "Release" goes out and the output relay is de-energised.

Operating mode "Filling": level control for filling

Both PTC thermistor probes "Probe 1" and "Probe 2" must be con-

nected. The following applies to both probes in this operating mode:

If the PTC thermistor is exposed to air (not submerged in a liquid)

Product description

8RG 210

once the heat-up process of one probe is completed, the yellow LED

of the corresponding probe goes out. If the PTC thermistor of a

probe is submerged in liquid or if the heat-up process of the probe is

not yet completed or the probe is not connected or short-circuited,

the yellow LED of the corresponding probe lights up.

Logical connection between the two probe signals and an output sig-

nal: If both probes are no longer submerged in the liquid, the green

LED "Release" lights up and the output relay is energised. If both

probes are submerged in the liquid, the green LED "Release" goes

out and the output relay is de-energised.

Operating mode "Emptying": level control for emptying

Both PTC thermistor probes "Probe 1" and "Probe 2" must be con-

nected. The following applies to both probes in this operating mode:

If the PTC thermistor is submerged in the liquid, the yellow LED of

the corresponding probe goes out. If the PTC thermistor of a probe is

exposed to air or if the probe is not connected or short-circuited, the

yellow LED of the corresponding probe lights up.

Logical connection between the two probe signals and an output sig-

nal: If both probes are submerged in the liquid, the green LED "Re-

lease" lights up and the output relay is energised. If both probes are

no longer submerged in the liquid, the green LED "Release" goes out

and the output relay is de-energised.

General information

In case of a power failure, the relay is always de-energised. When

power is available again, both probes must either be exposed to air

or submerged in the liquid before release is possible. A start delay of

approx. 15 seconds prevents a release before the heat-up phase is

completed.

RG 210 can be operated with or without additional external devices.

The following types of additional devices can be used: visual and

audible alarm units, telecommunication devices, building control sys-

tems, building automation systems, pumps, valves, etc.

Product description

RG 210 9

3.2 Application examples

1Pump stop

2RG 210

3Probe 1

4Maximum level

Fig. 4: Application as level switch

1Pump On/Off

2RG 210

3Probe 1

4Probe 2

5Maximum level

6Minimum level

Fig. 5: Application as level control for filling/emptying

1RG 210

2AFRISO event

reporting system

3Internet

4Email

5Mobile phone

6Fax

7Phone

Fig. 6: Remote reporting with AFRISO event reporting system

Specifications

10 RG 210

4 Specifications

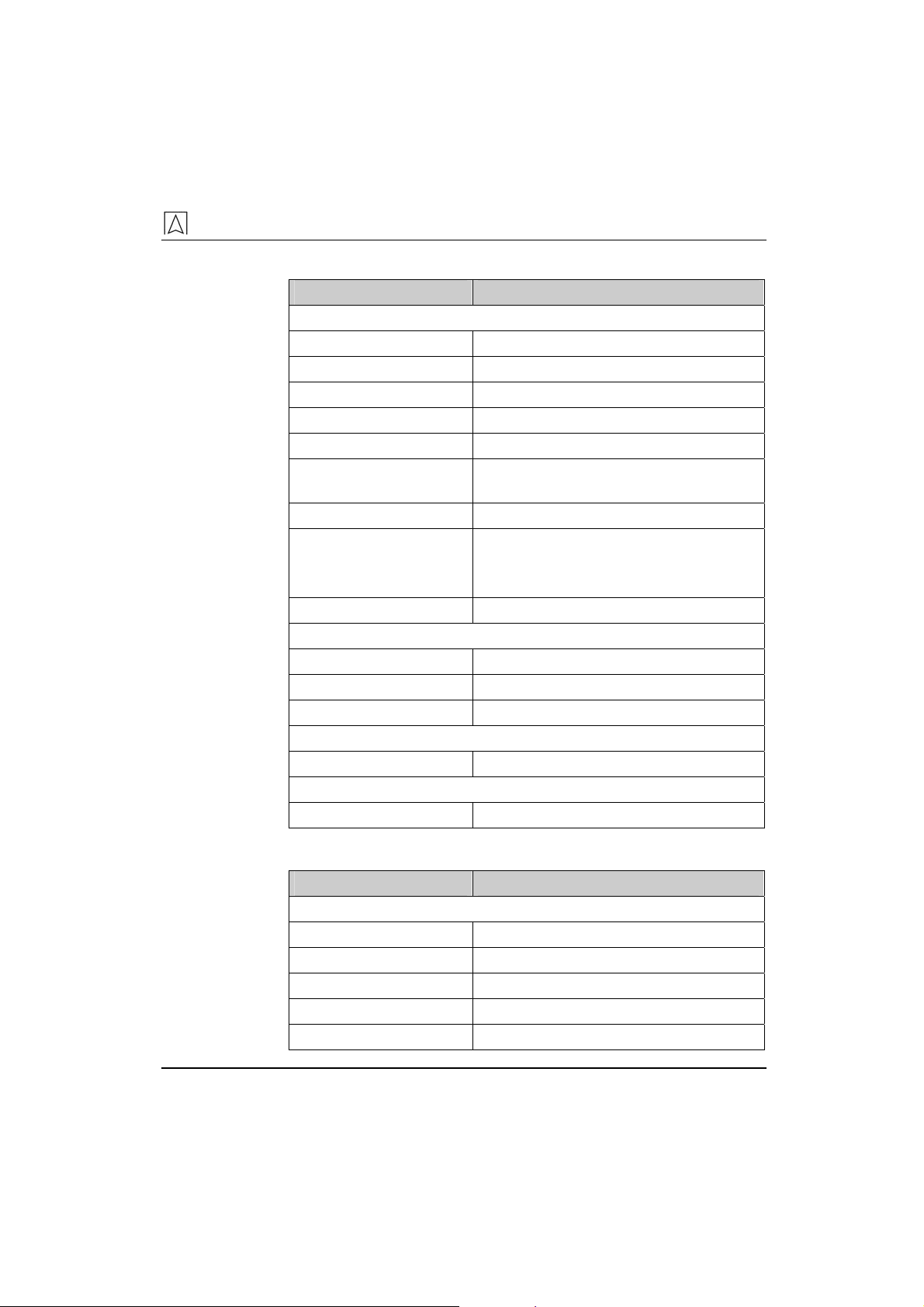

Table 1: Specifications control unit

Parameter Value

General specifications

Dimensions (W x H x D) 53 x 113 x 108 mm

Weight 0.55 kg

Response delay None

Indication of probe signals 2 yellow LEDs

Indication of output signal 1 green LED

Outputs 1 output relay (changeover con-

tact)

Connections For 2 PTC thermistor probes

Operating temperature range

Ambient -10 °C to +55 °C

Storage -10 °C to +60 °C

Supply

Supply voltage AC 230 V ± 10 %, 50 Hz

Rated power Max. 12 VA

Mains fuse M 100 mA (5 x 20 mm)

Breaking capacity output relay Max. 250 V, 2 A, resistive load

Electrical safety

Electrical safety EN 61010

Protection class II DIN 57700

Protection IP 30 EN 60529

Electromagnetic compatibility (EMC)

Noise suppression EN 61000-6-3

Noise immunity EN 61000-6-2

Specifications

RG 210 11

Table 2: Specifications probe type 150 (not included)

Parameter Value

General specifications

Dimensions (Ø x L) 14 x 57 mm

Weight 130 g

Screw connection Plastic, R1“, 1 bar

Weight Brass, Ø x L = 12 x 40 mm

Probe housing Plastic, Ø = 14 mm

Probe element Stainless steel-encapsulated PTC ther-

mistor

Resistance Refer to chapter 2.1, page 4

Connection cable

Standard length

Maximum length

Oilflex 2 x 0.5 mm²

3 m

50 m (screened)

Heat-up time Approx. 8 s

Operating temperature range

Ambient -25 °C to +75 °C

Medium -25 °C to +50 °C

Storage -25 °C to +75 °C

Supply

Probe voltage Max. DC 12 V

Electrical safety

Protection IP 68 EN 60529

Table 3: Specifications probe type 937 (not included)

Parameter Value

General specifications

Dimensions (Ø x L) 14 x 57 mm

Weight 130 g

Screw connection Plastic, R1“, 1 bar

Weight Brass, Ø x L = 12 x 40 mm

Probe housing Plastic, Ø = 14 mm

Transportation and storage

12 RG 210

Parameter Value

Probe element Wired PTC thermistor

Resistance Refer to chapter 2.1, page 4

Connection cable

Standard length

Maximum length

Oilflex 2 x 0.5 mm²

3 m

50 m (screened)

Heat-up time Approx. 8 s

Operating temperature range

Ambient -25 °C to +75 °C

Medium -25 °C to +50 °C

Storage -25 °C to +75 °C

Supply

Probe voltage Max. DC 12 V

Electrical safety

Protection IP 68 EN 60529

4.1 Approvals, tests and conformities

RG 210 conforms to the EMC Directive (89/336/EEC and

92/31/EEC) and the Low Voltage Directive (73/23/EEC and

93/68/EEC).

5 Transportation and storage

CAUTION Damage to the device due to improper transportation.

X Do not throw or drop the device.

X Protect the device from wetness, humidity, dirt and dust.

CAUTION Damage to the device due to improper storage.

X Protect the device against shock when storing it.

X Store device in a clean and dry environment.

X Store device only within its permissible temperature range.

X Protect the device from wetness, humidity, dirt and dust.

Installation and commissioning

RG 210 13

6 Installation and commissioning

;

The control unit and the probes must not be installed in hazard-

ous areas.

;

The control unit must be mounted to an even, rigid and dry wall

at eye level.

;

The control unit must be accessible and easy to oversee at all

times.

;

The control unit must not be reached by water or splash water.

;

The control unit must not be installed in damp rooms.

;

The maximum ambient temperature at the control unit must not

be exceeded, refer to table 1, page 10.

;

In the case of outdoor installation, the control unit must be pro-

tected from direct atmospheric influences.

;

A properly operating system requires the tank to be equipped

with an overflow pipe or an overfill alarm system according to

TRbF.

;

When the switch point is set, observe that the PTC thermistor

requires up to 15 seconds to heat up depending on the ambient

temperature.

The heat-up time of the PTC thermistor after loss of contact with a

liquid is approx. 30 seconds, depending on the liquid.

6.1 Installing the device

Control unit

1. Loosen the two housing screws at the front of the control unit

and remove the grey upper part of the housing from the black

base.

2. Mount the black base to the wall using two fastening screws

(DIN 96-4 x 35, though the mounting holes).

3. Connect the unit electrically as described in chapter 6.2,

page 14.

4. Select the operating mode as described in chapter 6.3, page 15.

5. Refit the grey upper part of the housing to the black base and

fasten it with the two housing screws.

Make sure the contact bar of the printed circuit board does not

damage the contact springs of the black base.

Installation and commissioning

14 RG 210

Probe

;

Splashes of the liquid may cause a premature response of the

PTC thermistor. Select an appropriate installation location.

X Fasten the PTC thermistor probe(s) at the desired tank

height(s).

X G1" threaded holes are required for installation in the tank

cover.

X If the probe is suspended without support, push the enclosed

brass weight over the cable all the way to the probe head so

that the probe head with the PTC thermistor always hangs down

vertically. The probe head must not float in the liquid.

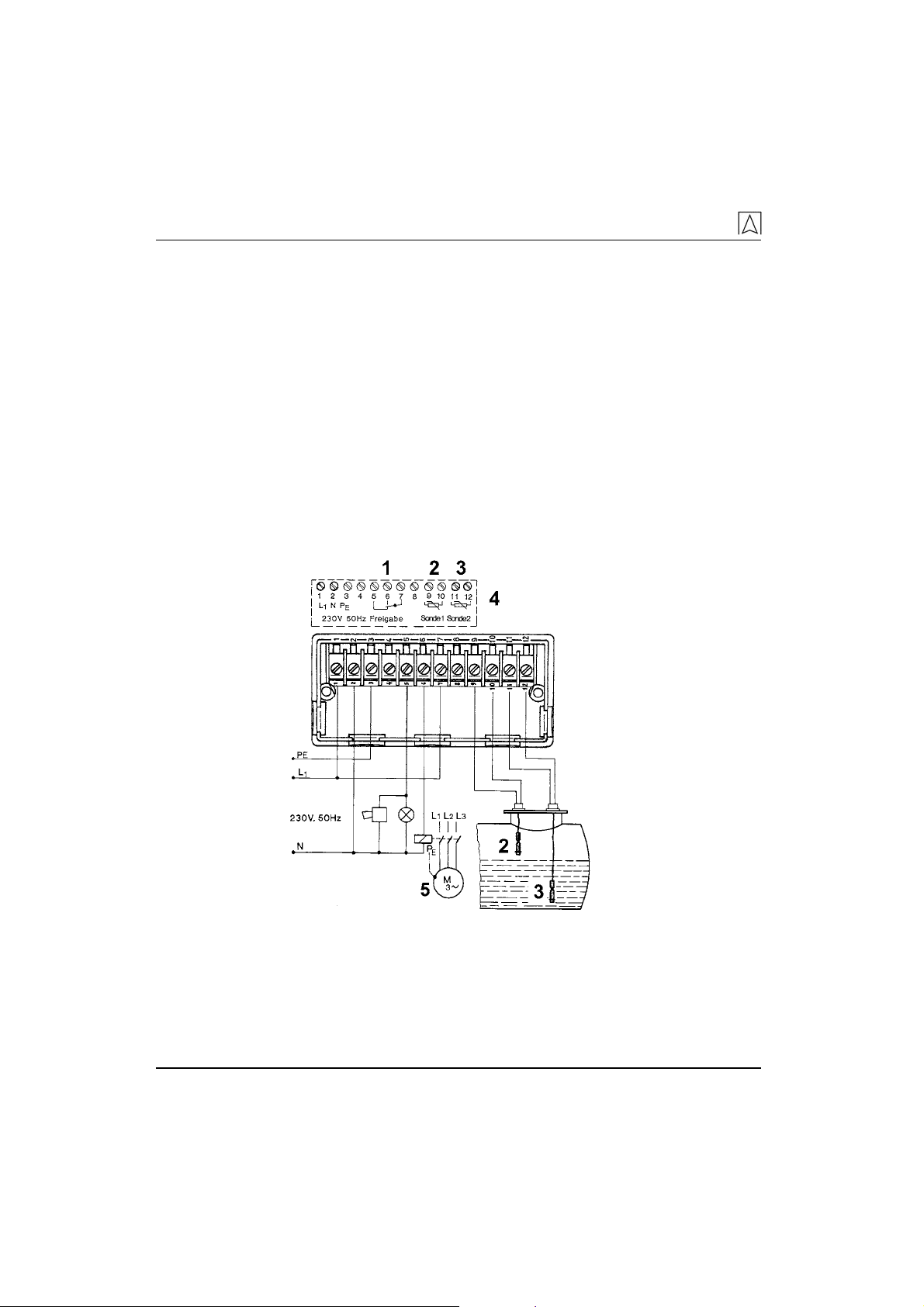

6.2 Electrical connection

;

Mains supply is disconnected and cannot be switched back on

by accident.

1Release

2Probe 1

3Probe 2

4Wiring diagram in

housing

5Pump

Fig. 7: Electrical connection

Installation and commissioning

RG 210 15

Power supply

;

Connect the level switch to mains by means of a permanently

installed cable such as NYM-J 3 x 1.5 mm².

1. Route the mains cable through the upper rubber cable gland

into the black base of the control unit.

2. The phase must be connected to terminal L1 , the neutral con-

ductor to terminal N and the protective conductor to terminal PE.

The control unit supply cable should be able to be switched off and

have a separate fuse (max. 16 A).

Probe

;

Do not route the probe cable next to mains cables; danger of in-

terference.

;

Protect the probe cable from damage; use metal pipes, if re-

quired.

1. The probe cable(s) must be permanently installed.

2. Route it/them through the bottom rubber cable glands of the

black base and connect them to the corresponding "Probe" ter-

minal(s).

You do not have to ensure a specific polarity.

Standard screened cable 2 x 0.5 mm² can be used to extend the

probe cable. The maximum length of the extension cable is 50 m.

Output

The output signal of RG 210 is made available via a voltage-free re-

lay contact (1 changeover contact).

1. The connection cable must be permanently installed.

2. Route it through the middle rubber cable gland of the black base

and connect it to the corresponding "Release" terminals.

CAUTION The switching contact may be destroyed by voltage peaks when

inductive consumers are switched off.

X Use commercially available standard RC combinations such as

0.1 µF/100 Ohm for inductive consumers.

Installation and commissioning

16 RG 210

6.3 Selecting the operating mode

;

The grey upper part of the housing has been removed from the

black base.

1. Loosen the grey cover from the upper part of the housing by

means of a small screwdriver and pull the printed circuit board

out of the upper part of the housing.

2. Set the slide switch (2) next to the green LED to the desired po-

sition.

3. Reassemble the device.

1Mains fuse F1

2Slide switch for

operating modes

3Operating mode

“Probe 1”

4Operating mode

“Filling”

5Operating mode

“Emptying”

Fig. 8: Selecting the operating mode

6.4 Commissioning the device

;

Control unit and probe(s) have been installed as per chapter 6,

page 13.

;

Electrical connection has been completed as per chapter 6.2

page 14.

;

Wiring has been checked.

;

Desired operating mode has been selected.

;

Control unit housing has been closed with screws.

If all prerequisites are met, the device is ready for operation.

1. Switch on the power supply via the on-site mains fuse.

ª

The connected PTC thermistor heats up.

Operation

RG 210 17

ª

The connected PTC thermistor(s) are heated up after approx.

8 seconds, provided they are not submerged in liquid.

2. Perfom a function test, refer to chapter 6.5, page 17.

6.5 Function test

1. Submerge the probe(s) in liquid.

ª

The yellow LEDs must light up immediately.

2. Remove probe(s) from the liquid.

ª

After approx. 8-15 seconds the yellow LEDs must change the

switching state.

3. Observe the green LED and the relay.

ª

The function sequence must correspond to the description of the

selected operating mode in chapter 3.1, page 7.

7 Operation

RG 210 automates the control of pumps and valves. The operation

of the RG210 is limited to its regular monitoring:

• Function check OK.

• Probe free from deposits.

8 Maintenance

8.1 Maintenance intervals

Table 4: Maintenance intervals

When Activity

Once per

year

X Perfom an operation test.

X Check the probe(s) for deposits.

There must be no deposits on the glass housing

of the PTC thermistor. If the PTC thermistor is pol-

luted, replace probe(s).

At regular

intervals

X Perform suitable checks to ensure that the level

switch and its environment are always clean, ac-

cessible and easy to oversee.

Troubleshooting

18 RG 210

8.2 Maintenance activities

Replacing the mains fuse F1

;

Mains voltage is interrupted and cannot be switched on by acci-

dent.

1. Loosen the two housing screws.

2. Remove the grey upper part of the housing from the black base.

3. Remove the grey cover from the upper part of the housing.

4. Pull the printed circuit board out of the upper part of the hous-

ing.

5. Replace the mains fuse F1, refer to table 1, page 10.

6. Push the printed circuit board into the upper part of the housing.

7. Fit the grey cover onto the upper part of the housing.

8. Push the upper part of the housing onto the black base.

9. Screw in the two housing screws.

10. Switch on the mains voltage.

9 Troubleshooting

Repair work may only be carried out by qualified, specially trained

personnel.

Table 5: Troubleshooting

Problem Possible reason Remedy

Mains voltage

interrupted.

X Check mains voltage.

Mains fuse de-

fective.

X Replace the mains

fuse, refer to chap-

ter 8.2, page 18.

Wiring defective. X Check wiring.

Yellow LEDs do not

respond when the

probe changes its

state.

Probe(s) defec-

tive.

X Check probe(s).

PTC thermistor is

polluted (deposits).

-X Replace probe(s).

Shutting down and disposal

RG 210 19

Problem Possible reason Remedy

Wrong operating

mode selected.

X Check operating

mode.

Wiring defective. X Check wiring.

Probes inter-

changed.

X Check probes.

Green LED and the

relay do not switch

as described in

chapter 3.1, page 7.

Control unit de-

fective.

X Replace control unit.

Other malfunction. – X Return the device to

the manufacturer.

10 Shutting down and disposal

1. Disconnect mains supply.

2. Remove the device (see chapter 6, page 13, reverse sequence

of steps).

3. To protect the environment, this device must not be disposed of

together with the normal household waste. Dispose of the de-

vice according to the local conditions and directives.

This device consists of materials that can be reused by recycling

firms. The electronic inserts can be removed easily and are con-

structed from recyclable materials.

If you do not have the opportunity to dispose of the old device in ac-

cordance with environmental regulations, please contact us for pos-

sibilities to dispose of it or to return it.

11 Spare parts and accessories

Part Part No.

Control unit 53206

PTC thermistor probes type 150 53208

PTC thermistor probes type 937 53204

Cable extension fitting KVA 40041

Mains fuse F1 (M 100 mA) 941571 0100

RC combination (0,1 µF/100 Ohm) 618 001 5100

Brass weight for probe installation 16 00 020901

Clamp for probe installation 16 00 101001

Event reporting system Phone Alarm SD1 90003

Warranty

20 RG 210

Part Part No.

Event reporting system GSM Alarm 90002

Event reporting system EMS 220 90220

Event reporting system EMS 442 90442

12 Warranty

The manufacturer’s warranty for this product is 24 months from date

of purchase. This warranty applies to all countries in which this pro-

duct is sold by the manufacturer or its authorised representatives.

13 Copyright

The manufacturer holds the copyright to this manual. This manual

may only be reprinted, translated, copied in part or in whole with the

prior written consent of the manufacturer.

We reserve the right to modify any specifications or alter any illustra-

tions in this manual without prior notice.

14 Customer satisfaction

Customer satisfaction is our prime objective. Please get in touch with

us if you have any questions, suggestions or problems concerning

your product.

15 Addresses

The addresses of our worldwide representatives can be found on the

Internet at www.afriso.com.

Table of contents

Other Afriso EURO-INDEX Controllers manuals