Chore-Time 28999 User manual

Introduction

The 28999 Drop Feeder Control is designed to be used

with a Chore-Time Drop Feeding System and Chore-

Time Flex-Auger®System.

The control will automatically open the Drop Feeders,

close the Drop Feeders, and start the fill system. The

system may also be operated manually.

The components of the control are housed in a dust proof,

water tight box. Liquid tight connectors must be used

when wiring into the control. The cover must be latched

in closed position unless switches or time clockis being

adjusted.

Wire the Drop Feeder Control, according to the

appropriate wiring diagram.

Setting the Control

Unlatch and open front cover.

Time Clock operation

Set the desired feeding time(s) on clock by sliding out sufficient tabs to allow for auger run time. Slide out one

additional tab for drop cycle (time required to open drops and close drops). Each tab represents 15 minutes. See

“Time Clock Features and Operation” on page 5 for clock setting information.

The lower toggle switch should be in the TIME CLOCK OPERATION position.

The upper toggle switch should be in the OFF position.

How it Operates

When the switch on the time clock is activated by the tabs, all drops will open at the same time. The drops will

automatically begin closing 15 seconds to 5 minutes after the clock is activated. This delay is adjustable

inside the control panel.

In multiple lift applications the #1 lift will completely close, then #2, etc. until all drops have closed. At that

time the fill system contactor and AUGER ENABLED Pilot Light will become energized and the fill system

auger(s) will refill the drop boxes. The switch in the Drop Feeder Control Unit will stop the fill system(s).

The fill system contactor and AUGER ENABLED Pilot Light will remain energized until the tabs no longer

activate the Time Clock Switch.

CAUTION: Only use the number of time clock tabs needed to fill the system plus one extra tab.

Manual Operation

Set the lower toggle switch to the MANUAL OPERATION position. The Time Clock is now disabled and the

drops may be opened or closed using the upper toggle switch.

The upper toggle switch should be in the OFF position when not in use.

MA922-7D

Drop Feeder Control

Part Number 28999

CTB Inc.

P.O. Box 2000 • Milford, Indiana 46542-2000 • U.S.A.

Phone (574) 658-4101 • Fax (877) 730-8825

Drop Feeder Control

2MA922F

How it Operates

Set the upper toggle switch to the OPEN DROPS position and the drops will open. Set the upper toggle switch

to the CLOSE DROPS AND FILL position, and the drops will close. When the balls are fully seated the fill

system contactor and AUGER ENABLED Pilot Light will become energized. The switch in the Drop

Feeder Control Unit will stop the fill system.

Close the cover and secure latch to keep moisture and contamination from entering box and voiding warranty.

Drop Feeder Control Internal Wiring Diagram (Feed-Fill)

RED

BLACK

RED

BLACK

GREEN

BLACK

ORANGE

RED

BLUE

YELLOW

YELLOWORANGE

L2

L1

2526-286

230V 1PH

TO FILL

CONTACTOR

ORG

RED

YELLOW

ORANGE

GREEN

BLACK

RED

WH

L1

L2

BLACK

TO

230V 1PH

SUPPLY

BLK

RED

BLUE

YELLOW BLACK

BLACK

YELLOW

YELLOW

RED

BLACK

BLUE

ORANGE

YELLOW

ORANGE

BLUE

RED

RED

230V 1PH

POWER

PACK

RED BLACK

YELLOW

MA922-3 10/95

Drop Feeder Control

3

MA922F

Internal Wiring Changes for converting a standard 28999 Drop Feeder

Control Panel to a Feed-Delay Fill style control

In this mode of operation the drops will be full of feed at feeding. The refilling will be delayed to a preset time of

choice. After the balls have been lifted to allow feeding, the ball will remain in the up position until time to refill

the feed boxes.

The control will need to be wired as shown to run as a delay fill system, See Figure 1.

Figure 1. Standard Control converted

Instructions for setting the time clock, See Figure 2. Push in all the tabs between the selected feed time and fill

time. With the time clock set this way it will delay filling of the boxes.

STEP 2

MA922-6 10/95

CONNECT BLACK WIRE HERE

CONNECT RED WIRE HERE

STEP 4

ORANGE

230V 1 PH

SUPPLY

STEP 3

DISCONNECT RED WIRE HERE

230 V 1 PH

TO FILL

CONTACTOR

STEP 1

DISCONNECT BLACK WIRE HERE

L2

L1

RED

BLK

ORG

WH

L2

L1

BLACK

TO

230 V 1 PH

POWER PACK

DISCONNECT YELLOW WIRE

STEP 5

RED

YELLOW YELLOW

AT BOTH ENDS AND DISCARD

Drop Feeder Control

4MA922F

Drop Feeder Control Internal Wiring Diagram (Feed-Delay Fill)

RED

BLACK

RED

BLACK

GREEN

ORANGE

RED

BLUE

ORANGE

L2

L1

2526-286

230V 1PH

TO FILL

CONTACTOR

ORG

RED

YELLOW

ORANGE

GREEN

BLACK

RED

WH

L1

L2

BLACK

TO

230V 1PH

SUPPLY

BLK

RED

BLUE

YELLOW BLACK

BLACK

YELLOW

YELLOW

RED

BLACK

BLUE

ORANGE

YELLOW

ORANGE

BLUE

RED

RED

230V 1PH

POWER

PACK

RED BLACK

YELLOW

MA922-8 10/95

BLACK

Drop Feeder Control

5

MA922F

Time Clock Features and Operation

• The outside edge of the clock face is a series of tabs.

• Use a finger nail of small screw driver to push tabs out.

• Each white tab on the time clock is equivalent to 15 minutes.

• Turn the white minute hand clockwise until the real time (actual time of day) is lined up with white arrow on

inner clock face.

•Do not turn the hand counter-clockwise! This will strip out the nylon gears and void your warranty.

Also, never adjust the time clock by turning the outer dial.

Drop Feeder Control (with Single Linear Actuator) Wiring Diagram

Time of Day (AM & PM Format)

Pull tabs as required for feeding cycle

(1hr. shown)

When adjusting, turn minute hand

clockwise only.

Figure 2. Setting Time Clock

Drop Feeder Control

6MA922F

Drop Feeder Control (with Multiple Linear Actuators) Wiring Diagram

Drop Feeder Control

MA922F 7

Drop Feeder Control (with One Linear-Lift™) Wiring Diagram

Drop Feeder Control

8MA922F

Drop Feeder Control (with Two Linear-Lifts™) Wiring Diagram

Drop Feeder Control

MA922F 9

Drop Feeder Control (with One MULTI-LIFT®and One Tower Switch) Wiring Diagram

Drop Feeder Control

10 MA922F

Drop Feeder Control Two MULTI-LIFT®/Two Tower Switches Wiring Diagram

Drop Feeder Control

11

MA922F

Drop Feeder Control Parts Listing (Part No. 28999)

Item Description Part No.

1 Pilot Light 7044

2 Control Box 28821

3 Push Nut Retainer 29879

4 10-32 Ground Screw 4968

5 #10 External Lock Washer 305

6 Corner Bracket 29013-1

7 Sheet Edge Insert 29878

8 Time Delay Relay (230 V) 29890

9 Fuse Block 7588

10 5 amp Normal Blow Fuse 7001

11 Mounting Plate 28689

12 Copper Lug 28822

13 Terminal Block 7270

14 ---- ----

15 Strapping 29014-2

16 Mounting Adapter 25480

17 Time Clock 26795

18 Front Panel 28685

19 Toggle Switch 20135

20 Toggle Switch 29727

Note: The original, authoritative version of this manual is the English version produced by

CTB,Inc.oranyofitssubsidiariesordivisions,(hereafter collectivelyreferred to as "CTB").

Subsequent changes to any manual made by any third party have not been reviewed nor

authenticated by CTB. Such changes may include, but are not limited to, translation into

languages other than English, and additions to or deletions from the original content. CTB

disclaims responsibility for any and all damages, injuries, warranty claims and/or any other

claims associated with such changes, inasmuch as such changes result in content that is

different from the authoritative CTB-published English version of the manual. For current

product installation and operation information, please contact the customer service and/or

technical service departments of the appropriate CTB subsidiary or division. Should you

observe any questionable content in any manual, please notify CTB immediately in writing

to: CTB Legal Department, P.O. Box 2000, Milford, IN 46542-2000 USA.

Revisions to this Manual

Page No. Description of Change

7,8 Changed Wiring Diagrams to match Current Linear Lift.

Contact your nearby Chore-Time distributor or representative for additional parts and information.

CTB Inc.

P.O. Box 2000 • Milford, Indiana 46542-2000 • U.S.A.

Phone (574) 658-4101 • Fax (877) 730-8825

E-mail: poultry@choretime.com • Internet: http//www.choretime.com

Table of contents

Other Chore-Time Controllers manuals

Popular Controllers manuals by other brands

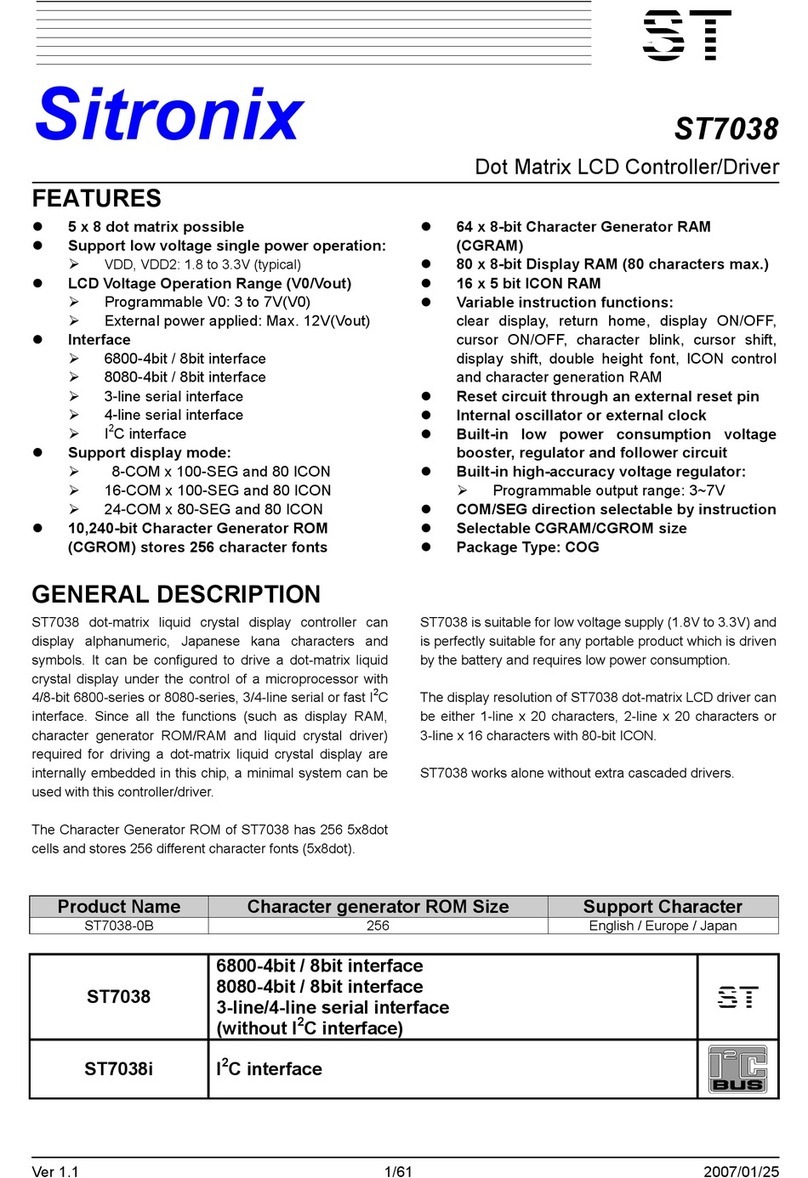

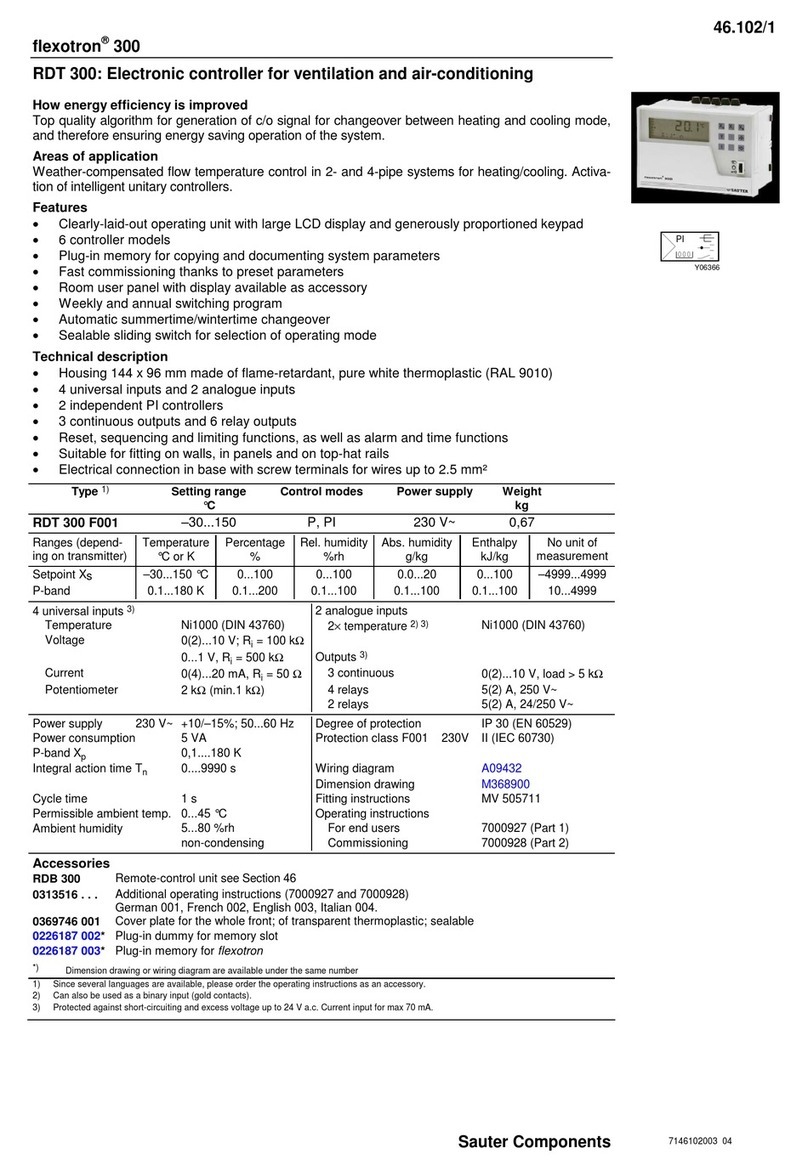

Sauter Components

Sauter Components flexotron 300 manual

cashco

cashco CLEAN STEAM Installation, operation & maintenance manual

Carel

Carel ir33+ quick start guide

SOMFY

SOMFY animeo IB + 1860085 installation guide

Ducasa

Ducasa Smart Command Installation and operating manual

Sensus

Sensus 441-S Installation and maintenance instructions