Afriso EURO-INDEX ARM User manual

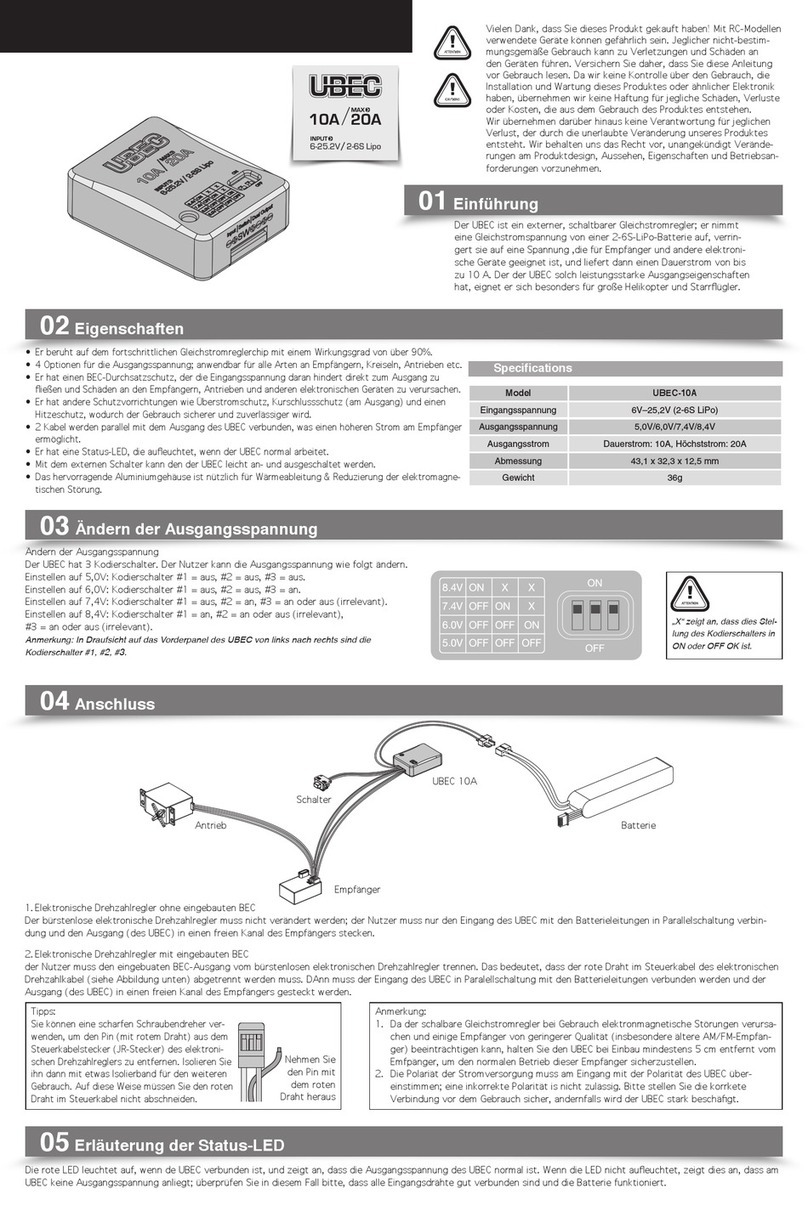

Figure 1

Figure 1.1

1. Fit the mounting element "b" to the

valve shaft and screw the locking

screw "c" into the valve. (fig 1).

Screw in the screw "h" to fixate the

actuator to the valve (fig. 1).

Select one of the adjustment scales

included with the actuator,

corresponding to the shut-off and

opening directions of the valve, and fit

it to the adjustment handle of

the actuator.

Connect the actuator as per

corresponding wiring diagram (fig. 4).

Remove the cap with the adjustment

scale from the adjustment handle

and fit the actuator to the valve in

Set the mixing valve to "50% open".

The regulating element must be

set exactly to the centre position

between the hot water supply and

the cold water supply in 3-way valve

(fig. 2.1) and exactly along the axis of

the supply to the system and the return

to the boiler in 4-way valve (fig. 2.2).

2.

3.

4.

5.

6.

1. Fit the mounting element "b" to the

valve shaft and screw the locking

screw "c" into the valve (fig. 1).

In the case of AFRISO ARV valves

(and in the case of most other valves),

mark "a" at the mounting element coincides

with the flat at the valve shaft; it also

indicates the centre position of the

regulating element in the valve

(fig. 2.1). You must loosen one of

the housing screws (fig. 1.1) so that the

locking screw can properly fit into the

ARV valves sizes DN40 and DN50.

3. Fit the actuator onto the valve. The actuator

is designed in such a way as to allow for

mounting to the valve in any position (fig. 2.2).

The indicator element at the blue ring "g"

should point upwards (fig. 1). If this element

has another position after you have fitted the

actuator, pull out the adjustment handle,

dismount the blue ring and refit it so that

the indicator element points upward. Then

plug on the adjustment handle (two

5. Fit the adjustment scale selected in section

4 onto the adjustment handle. The blue

indicator should show position "5" on the

adjustment scale. If the indicator has

a different position, the adjustment handle

has not been fitted as required. In this case,

go back to section 3.

6. Connect the actuator as per wiring diagrams

in fig. 4.

A. 3-point control: After you have

made the electrical connections, check

whether the actuator turns in the required

direction. If necessary, interchange wires

2 and 3.

B. 2-point control: You can change

the shut-off direction by changing the

position of the armature; dismount the

actuator housing to access it.

C. Versions with auxiliary switch:

One of the two black wires connected to

the auxiliary switch contacts has a red

connection. This wire should be connected

to the phase of the controlled system.

If this is not the case, the red signal LED

will not work properly.

D. Proportion control: After you have made

the electrical connections, make the

following settings by means of a micro-

switch which is accessible after you have

opened the actuator housing:

• Time for rotation by 90° (60/90/120 s),

• Type of control signal (U / I),

• Range of control signal (0..10 V / 2..10 V

or 0..20 mA / 4..20 mA).

2. 3-way mixing valve: Determine the operating

range of the regulating element and the

shut-off direction of the mixing valve and

then set the regulating element to 50% open

(fig. 2.1). First, determine the hot water

and the cold water supply of the valve

installed in the heating system. It should

be possible to move the regulating

element between the hot water supply

and the cold water supply within a range

of 90°. Then adjust the regulating element

exactly in the centre between the hot water

supply and the cold water supply (fig. 2.1).

During this phase, you should also

determine the valve shut-off direction

(shutting off the hot water supply) and

the valve opening direction (opening the

hot water supply).

4-way mixing valve: Determine the operating

range of the regulating element of the

mixing valve. To do so, determine the water

supply from the boiler, the water supply into

the system, the water return from the system

and the water return to the boiler. Then adjust the

regulating element exactly along the axis of

the supply to the system and the return to

the boiler (fig. 2.2) This corresponds to a valve

opening of "50%". The regulating element

should be operated in a range of +/-45° with

reference to this position.

4. Select the appropriate adjustment scale.

The actuator kit is delivered with two

adjustment scales: "from 0 to 10" and

"from 10 to 0". Hold them to the valve;

select the adjustment scale whose setting

"0" corresponds to the cold water supply

and whose setting "10" corresponds to the

hot water supply - as shown in fig. 2.1.

You may also use another simple rule to

select the adjustment scale.

- If the vale is to be closed by turning to the

right (clockwise), select the adjustment

scale "from 0 to 10".

- If the vale is to be closed by turning to the

left (counter- clockwise), select the

adjustment scale "from 10 to 0".

Electrical ARM Actuator

12

43

CAUTION!

The ARM actuator may only be installed, commissioned and dismounted by properly trained

staff. Only trained electricians may perform work on electrical circuits.

Any changes and modifications made by unauthorized staff may cause hazards and

are prohibited for safety reasons.

Depending on the version, the ARM actuator can be operated with

a mains voltage of 230 V. Mains voltage can cause severe

injuries or death.

The actuator must never come into contact with water.

Disconnect the supply voltage before opening the actuator.

No modifications whatsoever may be made to the actuator.

Mounting the actuator to the mixing valve

Mounting instructions

Detailed mounting description

The ARM actuator is factory-set to 50 % open (position "5" on the adjustment scale at the

adjustment handle). The mixing valve must also be set to a position of 50 % open so that the

actuator can be properly mounted to the valve. For this purpose, the regulating element must

be set exactly to the centre position between the hot water supply and the cold water supply

in 3-way valve and exactly along the axis of the supply to the system and the return to the

boiler in 4-way valve, after you have mounted the mounting element to the valve shaft and

tightened the locking screw. After you have set the mixing valve as described above, the valve

and the actuator are ready for mounting.

a mark

b mounting element

c locking screw

d actuator

e adjustment scale

f adjustment handle

g blue ring with indicator element

h fixing screw actuator

i fixing screw housing

j selector manual mode

Page

instrukcja prosta do pudelka.indd 1 11-04-05 10:50

Shut-off

direction

Cold water

Hot water

0

1

3

5

7

9

0

1

Figure 2.1

a

b

c

0

1

3

5

7

9

0

1

Shut-off

direction

Hot water

Cold water

a

d

i

g

f

h e

c

j

b

Supply from

the boiler

Shut-off

direction

1

0

9

7

5

3

1

0

Return to

the boiler

Supply to

the system

Return from

the system

Figure 2.2

notches at the circumference of the

adjustment handle should be positioned

horizontally) and screw in fixing screw

"h" (fig. 1).

such a way that the locking screw is

positioned one of the several grooves

at the rear wall of the actuator.

Four-way

Three-way

0

1

01

S4

0

1

S3

0

1

0...10 V / 0...20 mA

2...10 V / 4...20 mA

U/I

S5 S6

0 0

0 1

1 0

90s

120s

60s

0

1

U

I

Signal

S2

0

1

S1

1 1 120s

230 V (24 V) ~

N L

1 2 3 56

N

4

4

230 V (24 V) ~

N L

123

N

230 V (24 V) ~

N L

123

N L

230 V (24 V) ~

N L

1 2 3 56

N

4

4

L

AC 24 V

1 2 3

~

4

+-YU

~

+ - DC 24 V

YDC 0(2)...10 V

0(4)...20 mA

U DC 0(2)...10 V

Figure 4Figure 3

5 6

87

Page

Figure 5

Technical specifications

Warranty Customer satisfaction

Taking out of service, disposal

Approvals and certificates

Setting the auxiliary switch (selected versions)

Maintenance

Operation of the actuator

Procedure for setting the auxiliary switch:

1. 3.

5.

4.

2.

Loosen two fixing screws "i" and

remove the actuator housing (fig. 1).

Carefully push in the ring in such a way that

the end of the thicker section of the

circumference coincides with the specified

switch triggering angle.

Refit the upper part of the actuator housing

and tighten the fixing screws "i".

After the actuator has been set to position

"5" of the adjustment scale at the adjustment

handle (50 % open) and the valve opening

direction has been determined, set the angle

of the actuator (range 0 - 90°) at which the

function of the auxiliary switch is to be

triggered.

Carefully remove the switching ring

(fig. 5). The thicker ring section which

moves below the switch while the

actuator operates, applies pressure to

the lever and thus opens of contacts

4-5 of the auxiliary switch.The function

of the auxiliary switch (closing of

contacts 4-5) is initiated when the

thinner ring section faces the switch

which triggers the lever. At the same

time, the signal lamp lights up.

The AFRISO ARM actuator is maintenance-free.

3-point

2-point

proportional

3-point + auxiliary switch

3-point + auxiliary switch

The electrical actuator ARM complies with the Low Voltage Directive (LVD) (2006/95/EC),

Electromagnetic Compatibility Directive (EMC) (2004/108/EC) and Restriction

of Hazardous Substances Directive (RoHS) (2002/95/EC)

The electrical actuator ARM also complies with the following standards:

EN 60730-1, EN60730-2-14.

The warranty of the manufacturer for this

product is 36 months after the date of

purchase. The warranty shall be void if

unauthorised modifications are made to the

product or if the product is not installed in

compliance with these instructions.

Customer satisfaction is the prime objective of

AFRISO-EURO-INDEX. Please contact us at

suggestions or problems concerning product.

1.

2. Dismount the device.

3. To protect the environment, this

device must not be disposed of

together with non-separated

Disconnect the device from the

supply voltage.

commercial waste. Take the device to

an official waste disposal company.

The electrical actuator ARM consists of

recyclable materials.

1.Operating mode of the actuator

2.Indication via signal LEDs

The operating mode is set by means of

the selector for manual mode "j" (fig. 1).

Operating mode Automatic: The actuator

is in operating mode Automatic when the

selector "j" is in position .

Operating mode Manual: The actuator is in

operating mode Manual when the selector

"j" is in position .

Three signal LEDs are integrated into the

housing of the actuator. The outer LEDs

indicate the direction of rotation of the

actuator. The centre LED indicates the

operating state of the auxiliary switch

(depending on the version of the actuator).

3.Position of adjustment handle with

adjustment scale

After the actuator has been mounted to the

mixing valve and the proper adjustment

scale selected, position "0" means that the

valve is fully closed (hot water supply

closed) and position "10" means that the

valve is fully opened (hot water supply

open). The other settings of the adjustment

scale represent the degree of opening

(for example, "4" means that the valve is

open by 40%).

orange

(direction of rotation left)

orange

(direction of rotation right)

red

(auxiliary switch active)

Parameter Value

Torque Depending on version: 6 Nm, 10 Nm, 15 Nm

Rotation angle 90°

Time for turn by 90° Depending on version:

15 s, 30 s, 60 s, 120 s, 240 s, 480 s

Supply voltage / control signal 2-point - 24 V AC / 230 V AC

3-point - 24 V AC / 230 V AC

proportional - 24 V AC/DC

(0..10 V, 2..10 V, 0..20 mA, 4..20 mA)

Operating temperature range Setting in range 0 ÷ 90° (250 V AC, 3 A)

Power input 0 ÷ 50°C

Power consumption 2,5 ÷ 4 VA

Protection class II

Degree of protection IP42

Dimensions (H x W x D): 84 × 102 × 90 mm

Weight Version 6 Nm: 390 g ÷ 630 g

Version10 Nm and 15 Nm: 600 g ÷ 860 g

Housing material PC

instrukcja prosta do pudelka.indd 2 11-04-05 10:50

Other Afriso EURO-INDEX Controllers manuals