Maintenance

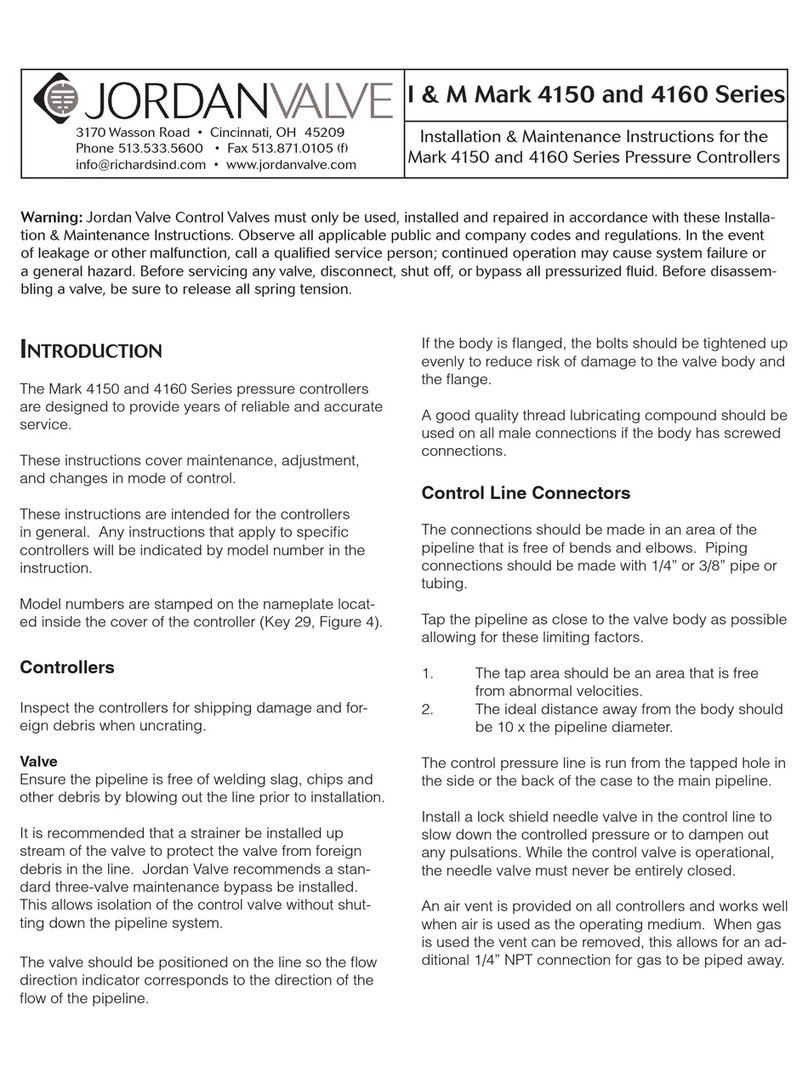

2. The control valve has been pre-set by Jordan Valve,

however, finer adjustment may be required to

compensate for the system conditions of your

application.

3. With inlet, outlet and bypass shutoff valves closed, and

no pressure in the down stream line, fully open the outlet

valve. Slowly open the inlet valve just enough to start

flow through the control valve. Increase the flow

gradually by slowly opening the inlet shutoff valve. Do

not fully open the inlet valve until you are sure that the

controller and control valve have control of the system.

Usually, the handwheel on the inlet valve will turn freely

when this point is reached.

4. To shut off the line fluid, close the inlet shutoff valve

first, and then close the outlet shutoff valve.

Caution: Make certain that there in no pressure in the

valve before loosening any fittings or joints. The

following steps are recommended:

1. Close the inlet shutoff valve.

2. Allow pressure to bleed off through the downstream

piping. Do not attempt to reverse the flow through the

valve by bleeding pressure from the upstream side of

the valve

3. When the pressure gauges indicate that all pressure

has been removed from the system, close the outlet

shutoff valve, and the valve may be serviced.

Note: refer to the drawing at the end of this document

for description and proper orientation of parts.

To reduce maintenance time, refer to proper figure and follow

steps indicated below for applicable maintenance operation.

Proposed Maintenance Procedure Follow Steps….

Renewing stem packing……………………..Packing

Replacement

Valve disassembly, inspecting

Parts, replacing plug or seat ring…………...Valve disassembly

Valve reassembly……………………………..Valve Reassembly

Actuator spring preload adjustment………..Actuator Spring

Load Adjustment

Actuator maintenance……………………......Actuator

Maintenance

Changing valve action……………………… Reversing Action

Motor valve seat spring preload…………….Motor Valve Seat

Spring Preload

Renew valve plug stem packing if control valve has been in

service beyond normal maintenance, and packing shows

signs of wear. Wear will be indicated by leakage, which

cannot be corrected by minor tightening of the packing

flange.An additional packing ring can be installed to

overcome minor leakage without dismantling the control

valve or breaking valve plug connection.

1. Remove the actuator from the bonnet. (See Removing

Actuator from Valve.)

2. Remove all of the packing and discard. Clean valve

stem and packing box thoroughly. The valve stem may

be dressed with a very fine crocus cloth, but generally

it is best not to as the stem has a fine machined finish.

Useapproved non-residue-forming solventfor cleaning.

Wipe dry with clean cloth.

3. Insert a new set of packing in packing box. Press each

ring down in place with a tube as it is installed.

4. After packing is installed, assemble packing adapter,

gland, and gland nuts. Tighten the nuts hand tight.

5. The final packing adjustment should be made with the

valvepressurized and thepacking tightened justenough

to stop any leakage, while stroking the valve.

Excessive tightening could cause the stem to stick

and result in improper valve operation due to high

friction forces.

PackingReplacement

RemovingActuatorfrom Valve

1a. Direct Acting Actuator (ATC): Shut off pressure to the

actuator and remove supply tubing from the actuator

case.

1b. Reverse Acting Actuator (ATO): Apply approximately 6

psig air pressure to the actuator to lift the plug off of

the seat.

1c. Motor Valve (Mark 709MV): Position the bottom inlet

to full open and disconnect all electrical connections.

2. Remove the actuator from the valve as follows: loosen

the two stem nuts and move them down the stem.

Lock these nuts together. Remove the two nuts that

secure the support legs to the bonnet. Using a wrench

on the nuts and on the flats of the actuator stem, turn

the valve stem (while holding the actuator stem in place)

until the stems disengage. The actuator will be free of

the valve.

Body & Bonnet Disassembly

1. For actuator removal, refer to section on “Removing

Actuator”.

2. Remove the body/bonnet bolts and carefully separate

the body from the bonnet so as not to damage delicate

trim components.

3. Remove stem nuts and indicator. Loosen the packing

gland nuts and withdraw the stem and plug out of the

bonnet. (The smaller trims have a one-piece stem and

plug, which can be withdrawn through the packing.)

4. With a socket wrench, remove both seats from the

body. Remove and discard the body/bonnet gasket.

5. Soft seats are disassembled by removing the seat cap

from the seat and then the soft seat can be removed.

6. Clean all parts with an approved non-residue-forming

solvent. Remove encrusted material with a very fine

Crocus or aluminum oxide cloth. However, do not use

these abrasives on the seating surface or the trim

surface (the portion of the plug that enters the seat

bore.) The machining tolerances on these surfaces are

so closely controlled that you might change the valves

flow characteristic.

7. Inspect all parts and replace and worn or damaged

parts. It is always advisable to replace seals and

gaskets. DO NOT attempt to resurface seating surfaces

of the plug or seat. Seats and plugs are only sold in

factory-matched sets.

ValveReassembly

1. Soft seated valves: insert soft seat into the seat cavity,

install the seat cap and tighten.

2. Lubricate the seat threads with a lubricant such as

NO-LOK and thread both seats into the body. Torque

to values shown.