2 PrimoBox AZB mixing units with low-loss header 200 and 300 series in cabinets

Table of Contents

1Explanations to the installation and operation manual............................................3

1.1 Safety messages and hazard categories.....................................................3

2Information on safety...............................................................................................3

2.1 Intended use.................................................................................................3

2.2 Quality control ..............................................................................................4

2.3 Qualification of personnel.............................................................................4

2.4 Modifications to the product .........................................................................4

2.5 Using additional parts and accessories .......................................................4

2.6 Liability .........................................................................................................4

3Product description..................................................................................................5

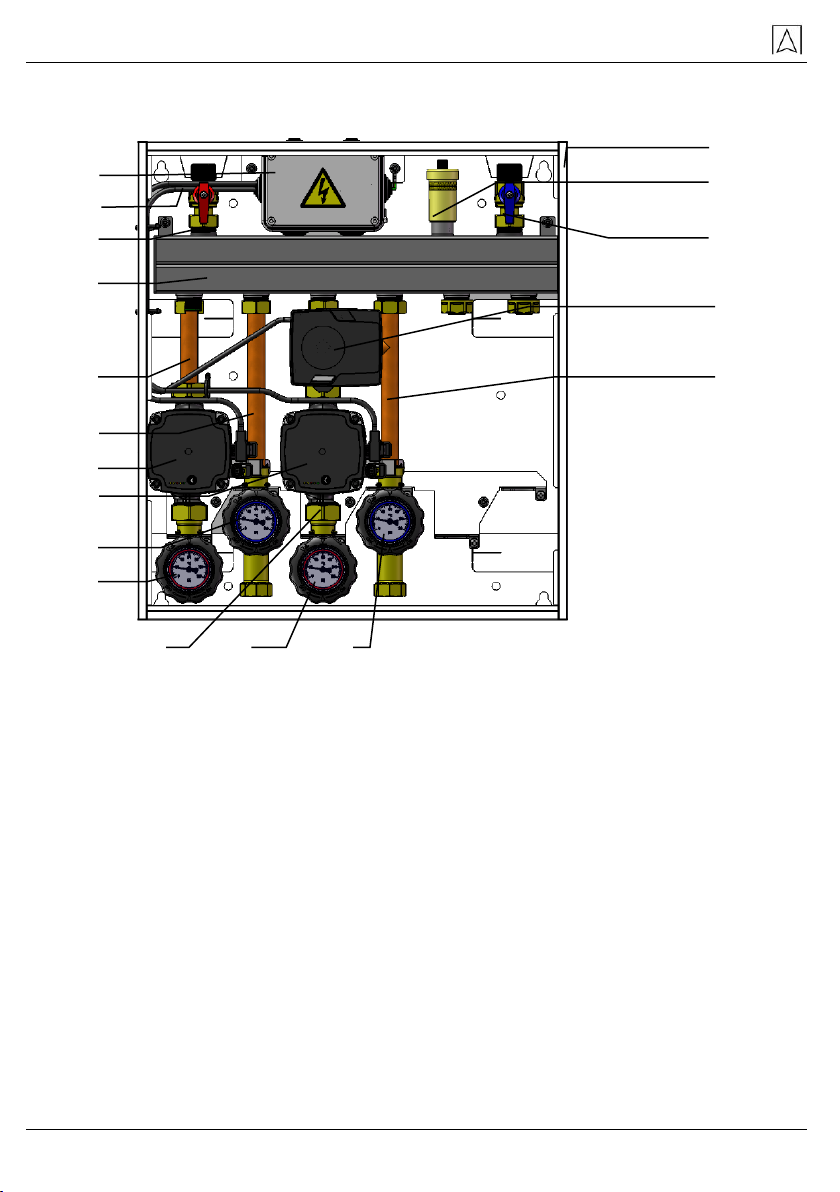

3.1 Construction.................................................................................................6

3.2 Dimensions...................................................................................................7

3.3 Operation......................................................................................................7

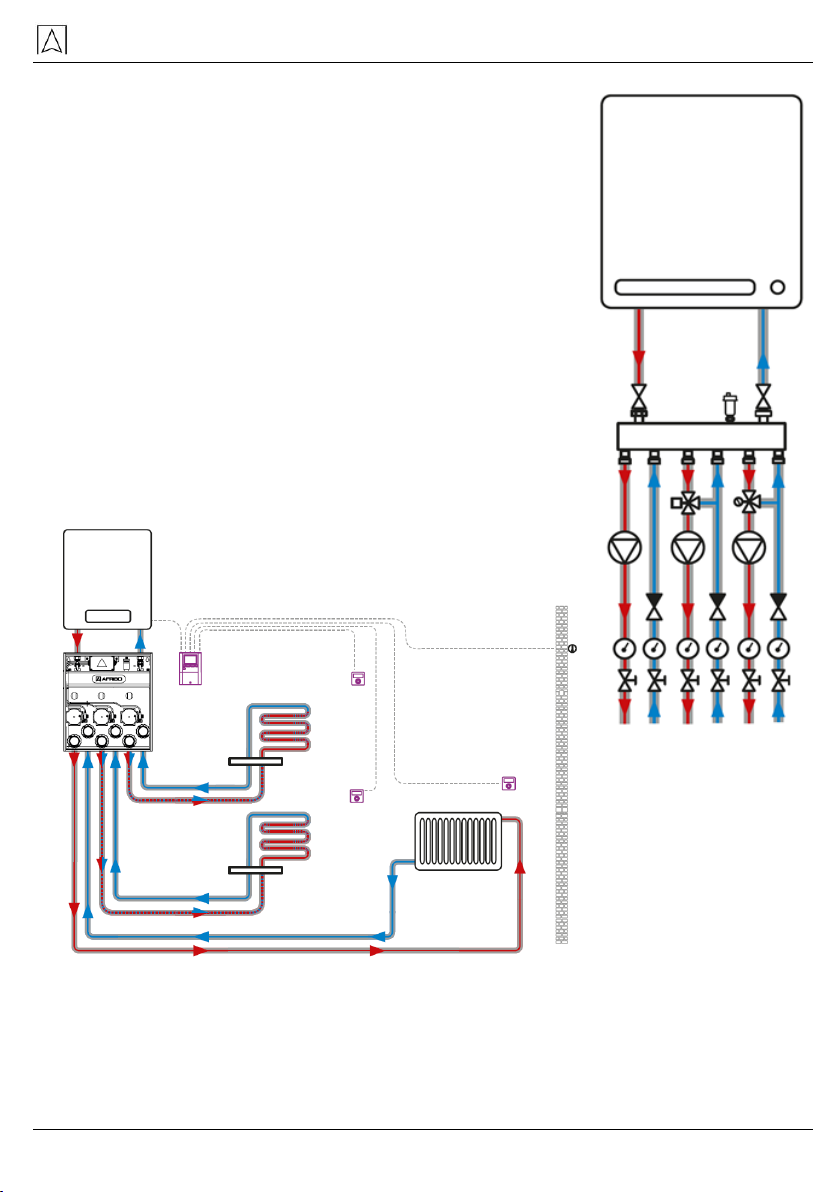

3.4 Hydraulic diagram sample............................................................................9

3.5 Sample application diagrams.......................................................................9

4Specification ..........................................................................................................10

4.1 Approvals ...................................................................................................10

4.2 Flow and available pressure diagrams ......................................................11

5Transport and storage...........................................................................................12

6Installation and commissioning .............................................................................13

6.1 Wall mounting.............................................................................................13

6.2 Flush mounting...........................................................................................14

6.3 Hydraulic connections................................................................................14

6.4 Electrical connections ................................................................................16

7Assembly and disassembly of ARM ProClick actuators........................................18

8Switching the actuator to manual operation..........................................................19

9Temperature setpoint with ATM thermostatic valve..............................................19

10 Decommissioning, scrapping ................................................................................20

11 Warranty................................................................................................................20

12 Copyright ...............................................................................................................20

13 Customer satisfaction............................................................................................20

14 Addresses..............................................................................................................20