PITSTOP DRIVE KITS ASSEMBLY MANUAL –

P1512180 R0 3

CONTENTS

1. Safety....................................................................................................................................................... 4

1.1 Safety Alert Symbol and Signal Words...................................................................................... 4

1.2 General Product Safety ............................................................................................................. 4

1.3 Moving Conveyor Belt Safety.................................................................................................... 4

1.4 Rotating Parts Safety................................................................................................................. 5

1.5 Work Area Safety ...................................................................................................................... 5

1.6 Guards Safety ............................................................................................................................ 5

1.7 Drives and Lockout Safety......................................................................................................... 5

1.7.1 Gas Engine Safety....................................................................................................... 6

1.7.2 Electric Motor Safety.................................................................................................. 6

1.7.3 Hydraulic Power Safety .............................................................................................. 7

1.8 Tire Safety.................................................................................................................................. 8

1.9 Personal Protective Equipment................................................................................................. 8

1.10 Safety Equipment .................................................................................................................... 9

1.11 Safety Decals ........................................................................................................................... 9

1.11.1 Decal Installation/Replacement............................................................................... 9

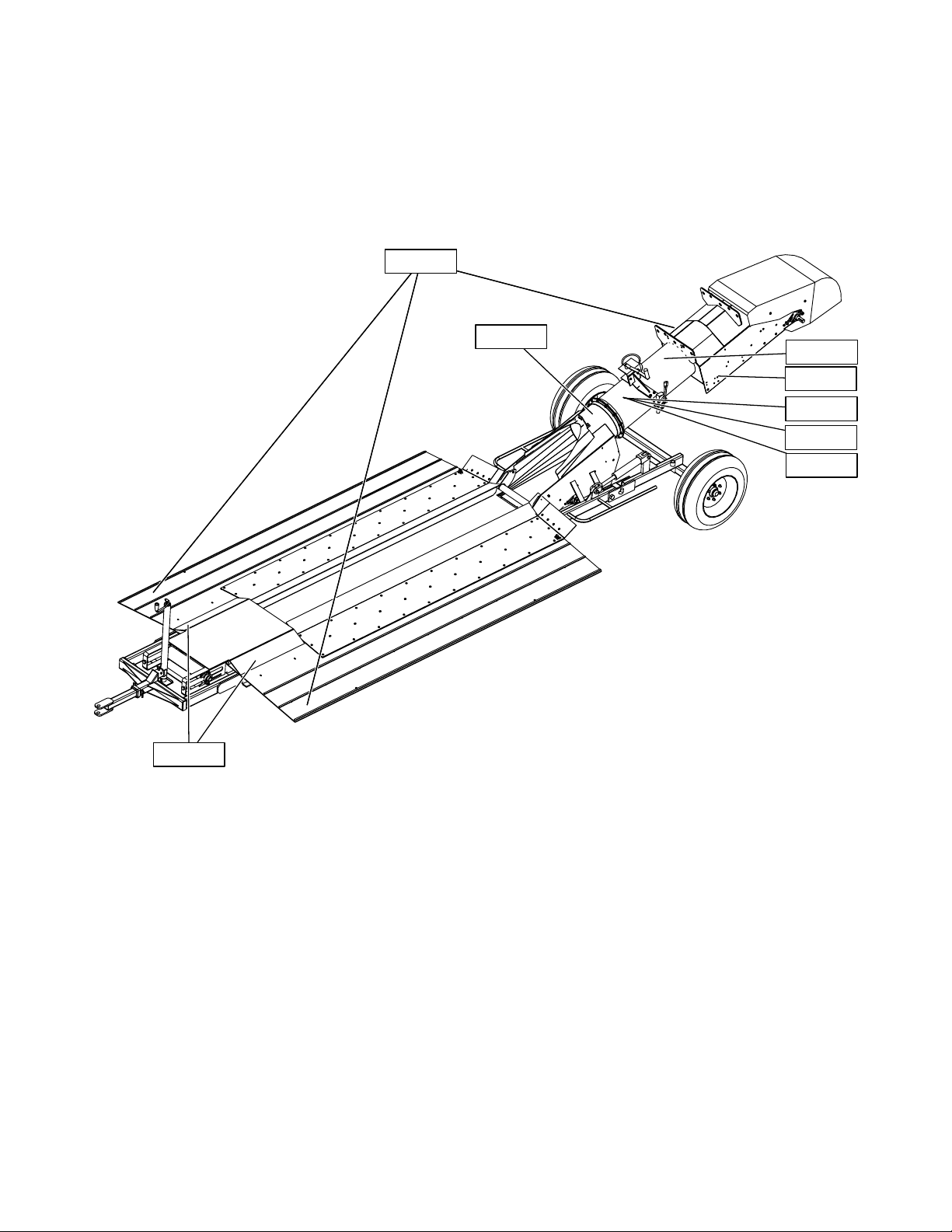

1.11.2 Safety Decal Locations and Details ........................................................................ 10

2. Assembly ............................................................................................................................................... 17

2.1 Assemble the Lift Hose............................................................................................................ 17

2.2 Install the Electric Drive .......................................................................................................... 18

2.2.1 Assemble the Motor Mounts................................................................................... 19

2.2.2 Install the Motor Mounts and Rails ......................................................................... 20

2.2.3 Install the Guard Mounting Brackets....................................................................... 21

2.2.4 Install the Motor ...................................................................................................... 22

2.2.5 Install the Pulleys, Drive Belts, and Tensioning Bolt................................................ 23

2.2.6 Install the Drive Belt Guard...................................................................................... 24

2.2.7 Install the Shaft Guard ............................................................................................. 25

2.3 Install the Hydraulic Wet Kit for the Electric Drive................................................................. 26

2.3.1 Install the Hydraulic Pump ....................................................................................... 27

2.3.2 Install the Hydraulic Tank......................................................................................... 32

2.3.3 Install the Hydraulic Fittings into the Flow Controller............................................. 33

2.3.4 Install the Hoses ....................................................................................................... 34

2.4 Install the Gas Drive ................................................................................................................ 35

2.4.1 Install the Drive and Battery Mounts....................................................................... 36

2.4.2 Install the Motor and Gearbox................................................................................. 40

2.4.3 Install the Battery and Fuel Tank ............................................................................. 46

2.4.4 Install the Guards ..................................................................................................... 49

2.5 Install the Hydraulic Drive ....................................................................................................... 52

2.5.1 Install the Hydraulic Motor ...................................................................................... 53

2.5.2 Install the Flow Controller........................................................................................ 58

2.5.3 Install the Hydraulic Fittings into the Lift Control ................................................... 62

2.5.4 Install the Hoses ....................................................................................................... 63

3. Limited Warranty.................................................................................................................................. 64