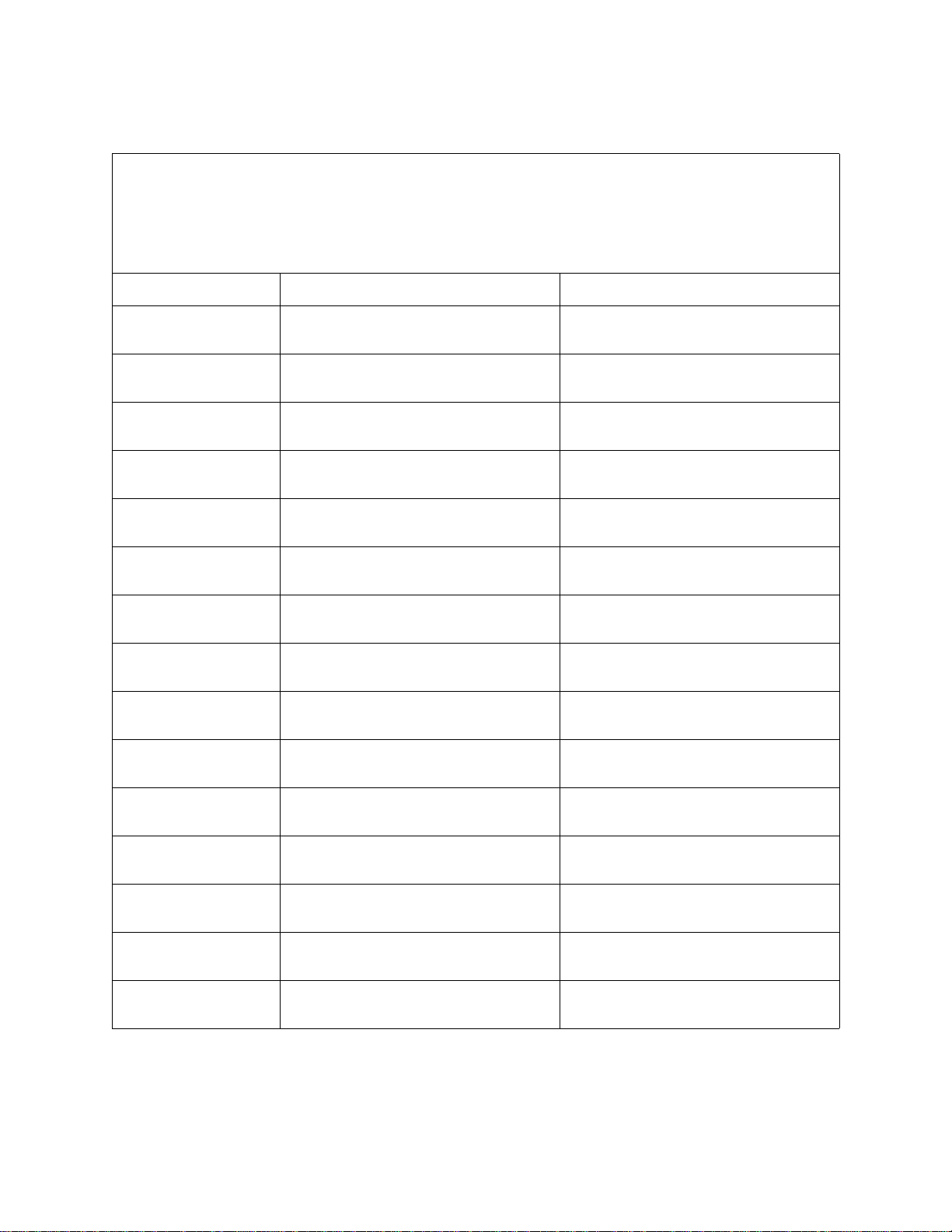

TABLE OF CONTENTS

HIROLLER - BELT CONVEYORS

HIROLLER, MINI ROLLER, LOROLLER & HILIFE

4P115506 R3

5. Installation .......................................................................................................................... 35

5.1. Pre-Installation........................................................................................................ 35

5.2. Head End & Tail End Trunking Installation............................................................. 35

5.2.1. Head Section Mounting ............................................................................ 35

5.2.2. Tail Section Mounting............................................................................... 37

5.2.3. Trunking Installation.................................................................................. 37

5.2.4. Tail Section Back Cover Removal & Installation....................................... 39

5.3. Inlet/Loader Installation .......................................................................................... 40

5.3.1. Skirt Installation ........................................................................................ 41

5.3.2. Discharge Considerations......................................................................... 42

5.4. Belt Installation....................................................................................................... 42

5.4.1. Pre-Installation.......................................................................................... 42

5.4.2. Belt Squaring & Cutting ............................................................................ 42

5.4.3. Splice Protector / Wiper Cleats................................................................. 46

5.4.4. Lubrication................................................................................................ 48

5.4.5. Belt Tension Procedure............................................................................ 48

5.4.6. Normal Idler Wear..................................................................................... 51

5.5. Leveling Tail Take-Up Section................................................................................ 52

5.6. V-Plow Adjustment................................................................................................. 52

5.7. Cover Installation.................................................................................................... 53

5.7.1. Made-To-Length Covers........................................................................... 53

5.7.2. Cut-To-Length Covers.............................................................................. 54

5.7.3. Cover Hardware........................................................................................ 55

5.8. Drive & Motor Final Check Before Start-Up............................................................ 56

5.9. Hazard Monitoring Devices .................................................................................... 56

5.9.1. Motion Sensor........................................................................................... 56

5.9.2. Plug Switch............................................................................................... 58

5.9.3. Belt Alignment Monitors............................................................................ 59

5.9.4. Belt & Pulley Alignment Monitors.............................................................. 68

5.10. Final Checklist...................................................................................................... 74

5.11. Test Start-Up........................................................................................................ 76

5.12. Final Inspection During Operation........................................................................ 76

6. Operation ............................................................................................................................ 79

6.1. Pre-Operational Checklist....................................................................................... 79

6.2. Conveyor Drive & Lockout Procedure.................................................................... 79

6.3. Operating Procedure.............................................................................................. 79

6.3.1. Start-Up and Break-In............................................................................... 79

6.3.2. Operating with a Full Load........................................................................ 80

6.3.3. Shutdown.................................................................................................. 80

6.3.4. Operating Tips.......................................................................................... 81

6.3.5. Plugging.................................................................................................... 81