Aginova Sentinel RS-485 DO User manual

Sentinel (RS-485) DO

Operation Manual

Sentinel (RS-485) DO • Operation Manual

Table of Contents

Chapter 1 Specifications .............................................................................................................................. 1

Chapter 2 Product Presentation ................................................................................................................. 2

Chapter 3 Installation .................................................................................................................................. 3

3.1 Installation of Sensors .................................................................................................................... 3

3.1.1 Quick Dismantling pool side fixed installation .................................................................. 4

3.1.2 Classic pool side fixed installation ..................................................................................... 5

3.1.3 Railing fixed installation .................................................................................................... 6

3.2 Connection of Sensor ..................................................................................................................... 7

Chapter 4 Interface and Operation ............................................................................................................ 7

4.1 User Interface ................................................................................................................................. 7

4.2 Parameter Setting ........................................................................................................................... 7

Chapter 5 Calibration of Sensor ................................................................................................................. 8

Chapter 6 Communication Protocol ........................................................................................................ 10

Chapter 7 Maintenance ............................................................................................................................. 14

7.1 Sensor Cleaning ............................................................................................................................ 14

7.2 Inspection on the Damage of Sensor ............................................................................................ 14

7.3 Preservation of Sensor .................................................................................................................. 14

7.4 Replacement of Fluorescent Cap .................................................................................................. 15

Tel:+1 513 204 5837

Web:https://www.aginova.com

1

Chapter 1 Specifications

Specifications Details

Measurement Range

DO:0~20mg/L or 0~200% saturability

Temperature: 0-45℃ with automatic temperature compensation

Measurement Accuracy

DO:±3% or ±0.3 mg/L, whichever is greater

Temperature: ±0.5℃

Repeatability ±0.3mg/L

Resolution 0.01mg/L

Pressure Range ≤0.3Mpa

Materials

SUS316L (Ordinary Version) , Titanium Alloy (Seawater Version)

Up and down cover: PPS + glass fiber, Cable: PUR

Power Supply 9~28VDC

Communication Protocol MODBUS RS485

Storage Temperature -15~60℃

Operating Temperature 0~45℃ (not freeze)

Weight 1.4KG

Level of Protection IP68/NEMA6P

Cable Length Standard: 10 m, the maximum can be extended 100m

Note: The specifications of the product are subject to change without prior notice.

Tel:+1 513 204 5837

Web:https://www.aginova.com

Sentinel (RS-485) DO • Operation Manual

2

Chapter 2 Product Presentation

The Sentinel (RS-485) dissolved oxygen sensor uses advanced fluorescence quenching

technology. When the blue light emitted by the sensor illuminates the fluorescent substance on the

fluorescent cap, the fluorescent substance is excited to emit red light, and since the oxygen molecule

can carry away the energy (quenching effect), the time and intensity of the excited red light and the

concentration of the oxygen molecule become in inverse proportion, the concentration of dissolved

oxygen in water can be obtained by calculation.

This product is widely used in the DO online monitoring of the regulating tank, biochemical tank

and effluent of sewage treatment plant.DO online monitoring in waterworks, surface water, water used in

various industrial production processes, aquaculture and other industries. The sensor appearance is shown

in Figure 1. The sensor size is shown in Figure 2.

Figure 1 Appearance diagram of Sentinel (RS-485) Dissolved Oxygen Sensor

1- Fluorescent cap 2- Temperature Sensor

3- R1 thread 4- Protective cap

Note: When using the sensor, please pull out the sensor protective cap (Series No.4),

Fluorescent cap (Series No.1) is the important part for the measurement function of this sensor. Do

not spin down the fluorescent cap (Series No.1).

Tel:+1 513 204 5837

Web:https://www.aginova.com

Sentinel (RS-485) DO • Operation Manual

3

The following figure shows the size of the fluorescence dissolved oxygen sensor:

Figure 2 Dimension diagram of Sentinel (RS-485) Dissolved Oxygen Sensor

Chapter 3 Installation

3.1 Installation of Sensors

Note: The protective cap should be removed before use before measurement. Do not screw

down the fluorescent cap.

Tel:+1 513 204 5837

Web:https://www.aginova.com

Sentinel (RS-485) DO • Operation Manual

4

3.1.1 Quick Dismantling pool side fixed installation

Figure 3 Quick Dismantling pool side installation sketch map

Tel:+1 513 204 5837

Web:https://www.aginova.com

Sentinel (RS-485) DO • Operation Manual

5

3.1.2 Classic pool side fixed installation

Figure 4 Classic pool side fixed installation sketch map

Tel:+1 513 204 5837

Web:https://www.aginova.com

Sentinel (RS-485) DO • Operation Manual

6

3.1.3 Railing fixed installation

Figure 5 Railing fixed installation sketch map

Tel:+1 513 204 5837

Web:https://www.aginova.com

Sentinel (RS-485) DO • Operation Manual

7

3.2 Connection of Sensor

The sensor should be correctly connected by the following definition of wire core:

Serial No. 1 2 3 4 5

Sensor Cable Brown Black Blue White Yellow + Green

Signal +12VDC AGND RS485 A RS485 B Ground lead

Chapter 4 Interface and Operation

4.1 User Interface

The sensor is connected to the computer using RS485 to USB, and then use Modbus Poll to connect

Note: Modbus Poll software is a general software that can be downloaded online.

4.2 Parameter Setting

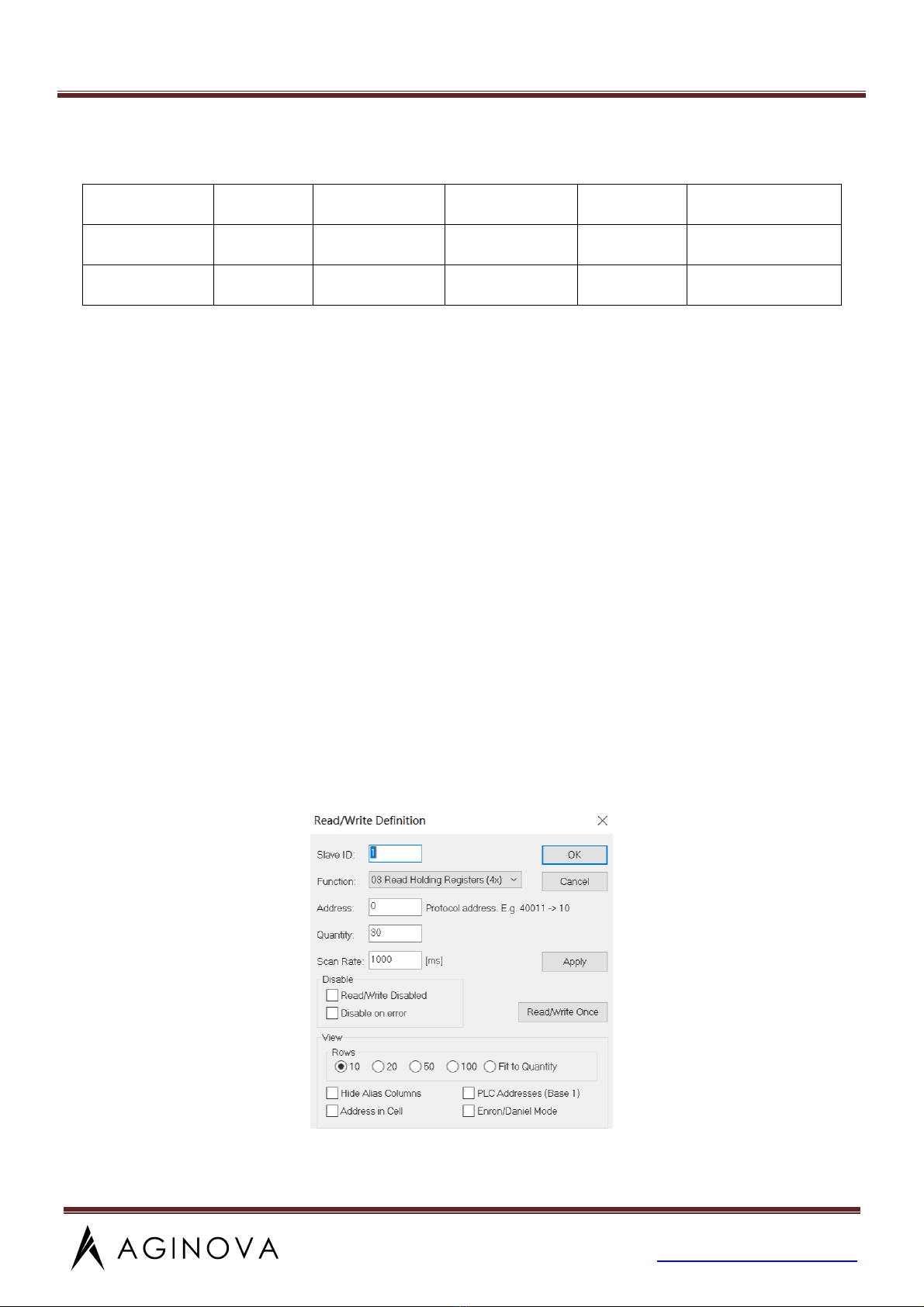

1、Click “Setup” on the menu bar, select “Read / Write Definition” and then set the parameters(The

slave address for the first time is the slave label), then enter “30” for Quantity in the dialog box , click

“OK”

Note: After the slave address is changed, the new address will be used for communication and the

slave address for the next time connection is also the most recently changed address.

Tel:+1 513 204 5837

Web:https://www.aginova.com

Sentinel (RS-485) DO • Operation Manual

8

2、Click “Connection” on the menu bar, select the first line in the drop-down menu “Connection

setup”(The baud rate for the first time is the slave label) and click “OK”.

Note: Port is set according to the Port number of the connection.

Note: If the sensor has been connected as described, and “Timeout Error” appears on the

software “Display status”, it means that the connection is failed; remove and replace the USB port

or check the USB to RS485 converter, repeat the above procedure until the sensor connection is

successful.

Chapter 5 Calibration of Sensor

The dissolved oxygen sensor has been calibrated at the factory and if you need to calibrate yourself,

follow the steps below

The specific steps of automatic air calibration are as follows:

Dry the sensor, add a small amount of water (25~50mL) to the calibration kit and shake the bag for a

few times. Then put the sensor into the calibration kit without touching the water and seal the

calibration kit with your hand to make the sensor in a saturated air. The sensor should be away from

light and high temperature and hard objects during calibration. The measured data is stable, Double-click

the “06”, and a dialog box pops out. Enter “27” for Address in the dialog box, “16” for Value, then click

“Send”.

Tel:+1 513 204 5837

Web:https://www.aginova.com

Sentinel (RS-485) DO • Operation Manual

9

Wait 20 seconds, change Value to “19” in the dialog box and click “Send”.

The specific steps of zero-point calibration are as follows:

Dry the sensor and place it in the anaerobic water until the measured data is stable, Double-click the

“06”, and a dialog box pops out. Enter “27” for Address in the dialog box, “12” for Value, then click

“Send”.

Wait 20 seconds, change Value to “19” in the dialog box and click “Send”.

Tel:+1 513 204 5837

Web:https://www.aginova.com

Sentinel (RS-485) DO • Operation Manual

10

Chapter 6 Communication Protocol

The sensor is equipped with MODBUS RS485 communication function, please refer to this

manual section 3.2 to check the communication wiring. The specific MODBUS RTU table is shown

in the following table.

MODBUS-RTU

Baud Rate 4800/9600/19200/38400/57600

Data Bits 8 bit

Parity Check no

Stop Bit 1bit

Register Name Address Data Type Register Number Read/Write Description

Dissolved Oxygen

Val ue

0 Float 2 R(only read)

Dissolved Oxygen

Concentration

2 Float 2 R

Temperature 4 Float 2 R

Slope 6 Float 2 W/R

Range:

0.5~1.5

Tel:+1 513 204 5837

Web:https://www.aginova.com

Sentinel (RS-485) DO • Operation Manual

11

Deviation Value 8 Float 2 W/R

Range:

-20~20

Salinity 10 Float 2 W/R

Atmospheric Pressure 12 Float 2 W/R

Baud Rate 16 Float 2 R

Slave Address 18 Float 2 R Range: 1~254

Response Time of

Read

20 Float 2 R

Modify Baud Rate 16 Signed 1 W

0-4800

1-9600

2-19200

3-38400

4-57600

Modify Slave Address 17 Signed 1 W Range: 1~254

Modify Response

Time

30 Signed 1 W

2~60s

(multiples of 2)

Air

Calibration

Step 1 27 Signed 1 W 16

Step 2 27 Signed 1 W 19

It should be cancelled if you don’t want to calibrate after the execution of “Step 1”.

Cancel 27 Signed 1 W 21

Zero-point

Calibration

Step 1 27 Signed 1 W 12

Step 2 27 Signed 1 W 19

It should be cancelled if you don’t want to calibrate after the execution of “Step 1”.

Cancel 27 Signed 1 W 21

Function Code

R:03

Write 06 as the reshaping data 06

Write 16 as the floating point data

485 analysis:

Tel:+1 513 204 5837

Web:https://www.aginova.com

Sentinel (RS-485) DO • Operation Manual

12

1、Read the slope

Register Name Address Data Type Register Number Read/Write Description

Slope 6 F 2 W/R Range:0.5-1.5

Send the command:01 03 00 06 00 02 24 0A

The equipment return:01 03 04 00 00 40 E0 CA 7B

Send command parsing:

01:device address 01

03:Function code 03 for reading register content

00 06:The starting register address read is 0006

00 02:Read 2 registers

24 0A:CRC16 check code

The device returns the analysis:

01:device address 01

03:Function code 03 for reading register content

04:The length of the returned data is 4 bytes

00 00 40 E0:The slope read is 7.00(analyze 40 E0 00 00 using IEEE 754)

CA 7B:CRC16 check code

2、Modify Slave Address

Register Name Address Data Type Register Number Read/Write Description

Modify Slave

Address

17 Signed 1 W Range: 1-254

Send the command: 01 06 00 11 00 0F 99 CB

The equipment return:01 06 00 11 00 0F 99 CB

Send command parsing:

01:device address 01

06:Function code 06 for writing register content

00 11:The register address of write data is 0017

00 0F:Write data content of 0015

Tel:+1 513 204 5837

Web:https://www.aginova.com

Sentinel (RS-485) DO • Operation Manual

13

99 CB:CRC16 check code

The device returns the analysis:

01:device address 01

06:Function code 06 for reading register content

00 11:The register address of the return write data is 0017

00 0F:Returns modified data content of 0017

99 CB:CRC16 check code

3、Set the slope

Register Name Address Data Type Register Number Read/Write Description

Slope 6 F 2 W/R Range:0.5-1.5

Send the command:01 10 00 06 00 02 04 00 00 3F 80 63 D5

The equipment return:01 10 00 06 00 02 A1 C9

Send command parsing:

01:device address 01

10:Function code 16 for writing register content

00 06:The starting register address write is 00 06

00 02:Write 2 registers

04:The length data is 4 bytes

00 00 3F 80:The slope write is 1.00(analyze 3F 80 00 00 using IEEE 754)

63 D5:CRC16 check code

The device returns the analysis:

01:device address 01

10:Function code 16 for writing register content

00 06:The starting register address of the return write data is 00 06

00 02:Returns 2 registers

A1 C9:CRC16 check code

Tel:+1 513 204 5837

Web:https://www.aginova.com

Sentinel (RS-485) DO • Operation Manual

14

Chapter 7 Maintenance

In order to obtain the best measurement results, it is very necessary to maintain the sensor regularly.

Maintenance mainly includes cleaning, inspecting damage of the sensor. You can also view the sensor’s

status during maintenance and inspection.

7.1 Sensor Cleaning

It is recommended that the sensor should be cleaned at regular intervals (usually 3 months,

depending on the site environment) to ensure the accuracy of the measurement.

Use water to clean the outer surface of the sensor. If there is still debris, wipe it with a damp soft

cloth. Do not place the sensor in a direct sunlight or near radiation. In the entire life of the sensor, if the

total sun exposure time reaches to one hour, it will cause the fluorescent cap aging and going wrong, and

consequently leading to the wrong reading.

7.2 Inspection on the Damage of Sensor

According to the appearance of sensor to check if there is damage; if any damage is found, please

contact after-sales service maintenance center in time for replacement to prevent malfunction of sensor

caused by water from the damaged cap.

7.3 Preservation of Sensor

A、When you are not using it, please cover the product’s original protective cap to avoid direct

sunlight or exposure. In order to protect the sensor from freezing, the DO probe should be stored in a

place where it will not freeze.

B、Keep the probe clean before storing it for a long time. Keep the equipment in a shipping box or a

plastic container with electric shock protection. Avoid touching it with hand or other hard objects in case

of scratching the fluorescent cap.

C、It is forbidden that the fluorescent cap is exposed to direct sunlight or exposure.

Tel:+1 513 204 5837

Web:https://www.aginova.com

Sentinel (RS-485) DO • Operation Manual

15

7.4 Replacement of Fluorescent Cap

The sensor's measurement cap needs to be replaced when it’s damaged. In order to ensure the

accuracy of the measurement, it is recommended to change it every year or it is necessary to be replaced

when the cap is found severely damaged during the inspection.

Steps to replace the fluorescent cap: Unscrew the old cap from the sensor, and then screw the

new cap on.

Note: When removing and installing fluorescent cap, pay attention to whether the sealing ring

is out of position. If there is a mismatch, it must be reassembled.

version number:R1010_200601

Tel:+1 513 204 5837

Web:https://www.aginova.com

Sentinel (RS-485) DO • Operation Manual

Table of contents

Other Aginova Accessories manuals