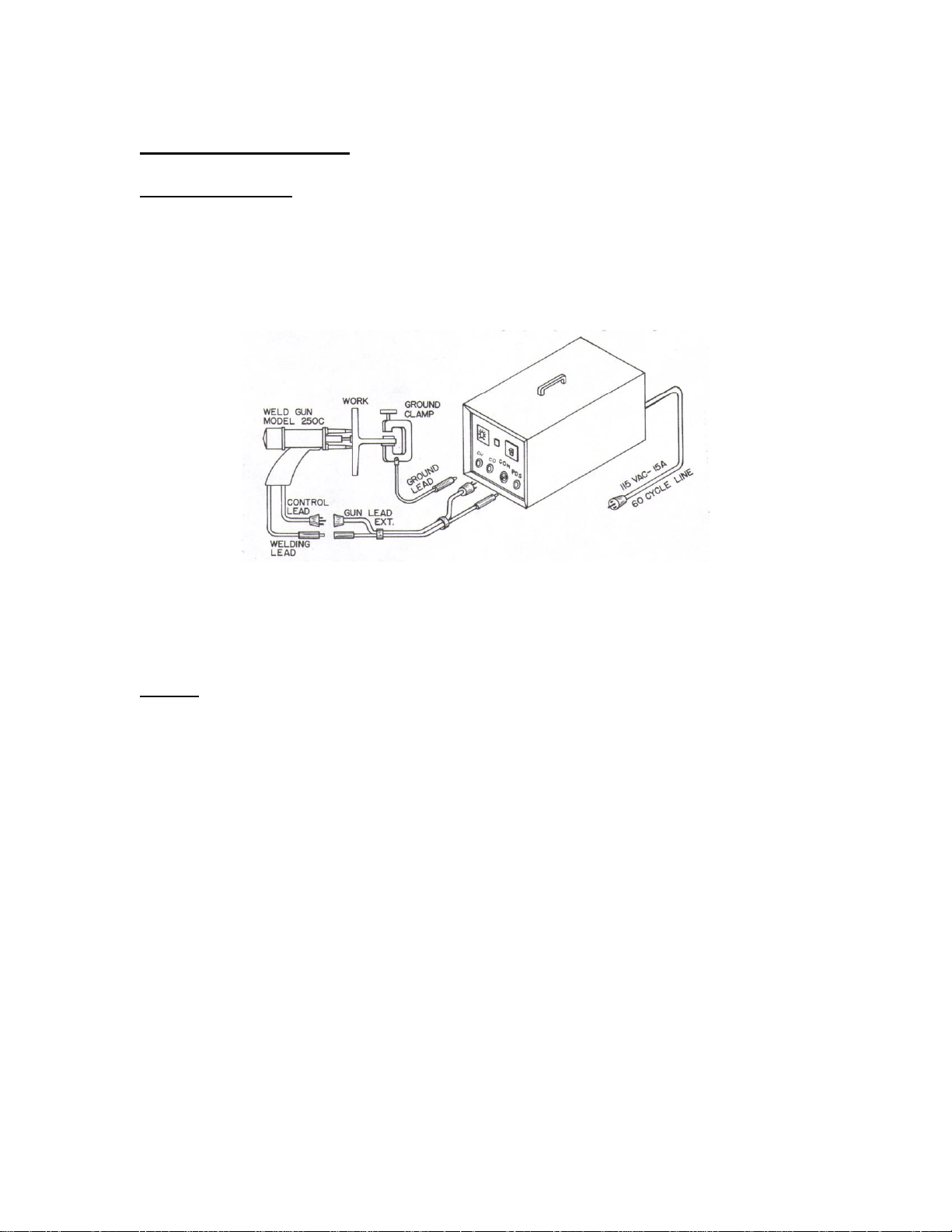

WELDING OPERATION

1. Adjust the voltage control to the desired setting for your application.

2. Turn the AC line switch “on”. The Amber Weld Ready Light will glow within

three seconds, indicating that the weld capacitors are charged and the unit is

ready to weld.

3. Insert a weld stud or pin through the collet protector (when used) and into the

collet. Make sure the stud/pin is inserted as far as it will go.

4. Position the three legs of the gun firmly against the work piece. When the

stud makes contact with the work the ready light will go off.

5. Holding the gun firmly, depress the trigger switch. The power pack will then

automatically control the weld cycle.

6. Once the cycle is complete, the trigger switch should be released and the gun

removed from the stud or pin in a “straight line motion”. This will help avoid

bent studs or pins and possible damage to the collet and protector.

It is suggested that periodic inspection of the welds be made to ensure weld strength

and proper system operation.

If Amber Weld Ready Light fails to glow within three seconds turn machine off and

disconnect from power source to avoid serious damage to your welder!

INSPECTION OF WELDS

1. VISUAL

A good quality weld will have a minimal but even amount of splatter around the base

of the stud/pin. Excessive splatter indicates that the voltage is set too high. When no

splatter appears or a void exists around the base, this indicates the voltage is set too

low. Adjust the voltage as necessary.

2. BEND TEST

Several tests welds should be made onto a base material similar to the welding

surface. The stud/pin should be bent back and forth with a piece of tubing or by

striking with a hammer. Failure should occur at the shank portion of the stud/pin, not

at the weld base. In the case of thin base metal, a plug may pull out of the base.

3. TORQUE TEST –THREADED STUDS

Make several test welds onto similar base metal. Place a few washers over the stud,

and thread on a nut. Continue turning the nut until a failure occurs. The failure should

be at the root diameter of the threads, not the weld base. In the case of thin base

metal, a plug may pull out of the base.