2 Two-wheel tractor 3900 Edition 04.97

Index

Amount of Delivery ........................... 3

Recommendations

Lubricants ......................................... 4

Maintenance and Repair .................. 4

Fuel ................................................... 7

Designation

of Parts ...................... 5, 9, 61, 65, 69

Assembly Instructions ................... 8

1. Safety Instructions ............. 11–16

2. Specifications

Dimensions ..................................... 18

Track Width..................................... 18

Machine .......................................... 19

Vibration Acceleration Value .......... 19

Petrol Engine .................................. 19

Diesel Engine.................................. 20

Noise Levels ............................. 19, 21

Operation on Slopes................. 19, 21

3. Devices and Operating Elements

Engine............................................. 22

Safety Circuit .................................. 23

Clutch.............................................. 23

Gearbox .......................................... 24

Single-Wheel Brake ........................ 24

Central Brake .................................. 25

Differential Gear ............................. 25

PTO................................................. 26

Reversing Lock ............................... 26

Steering Handle ........................ 27, 28

Drive-Wheels .................................. 29

Wheel Fastening Bolts.................... 29

Snow Chains................................... 29

Front Weight ................................... 30

Support leg ..................................... 30

Coupling and Decoupling

Attachments.................................... 31

Electric Starter Version................... 37

4. Commissioning and Operation

Commissioning the Machine .......... 36

Before you operate the machine .... 37

Starting the Petrol Engine .............. 38

Switching off the Petrol Engine ...... 39

Starting the Diesel Engine........ 40, 41

Switching off the Diesel Engine...... 42

Operations ...................................... 43

Driving with Mounted Trailer........... 44

5. Maintenance

Petrol Engine ............................ 45–48

Diesel Engine............................ 49–52

Machine .......................................... 53

Adjustments on Hand Levers ......... 54

Battery ............................................ 55

General ........................................... 55

Storage ........................................... 56

6. Troubleshooting ................. 57–59

Lubricants, Varnishes,

Wear Parts ............................... 63–64

Electrical Wiring Diagrams.... 67–68

Inspection and

Maintenance Chart ....................... 72

Conformity Declaration................ 73

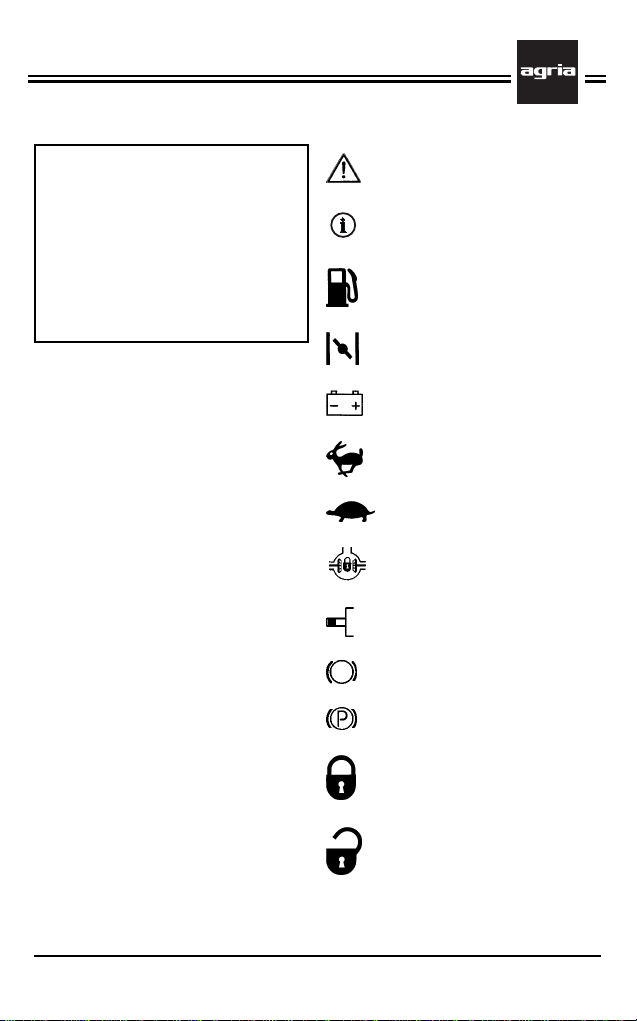

Note fold-out pages!

Fig. A + B ......................................... 5

Fig. B + C ......................................... 9

Fig. D + E, Petrol ........................... 62

Fig. F + G, Diesel, recoil starter .. 66

Fig. H + J, Diesel, electric starter 70