F-3827 1 of 4 12-9-2004

ASSEMBLY MANUAL 2-7282

TRACTOR & BACKHOE GENERAL INFORMATION

Tractor must be equipped with sufficient counterweight

at front of tractor, such as a front end loader, for backhoe

installation.

Complete backhoe installation requires hose kit or

pump kit. Install backhoe hydraulic kit before mounting

backhoe.

IMPORTANT: Remove linch pins and disconnect

supports to disable 3-point hitch arms before installing

backhoe subframe.

Reference to left and right as used in these instructions

refer to direction when seated in operating position on

backhoe. Backhoe subframe can be installed on tractor

and backhoe using tools ordinarily available.

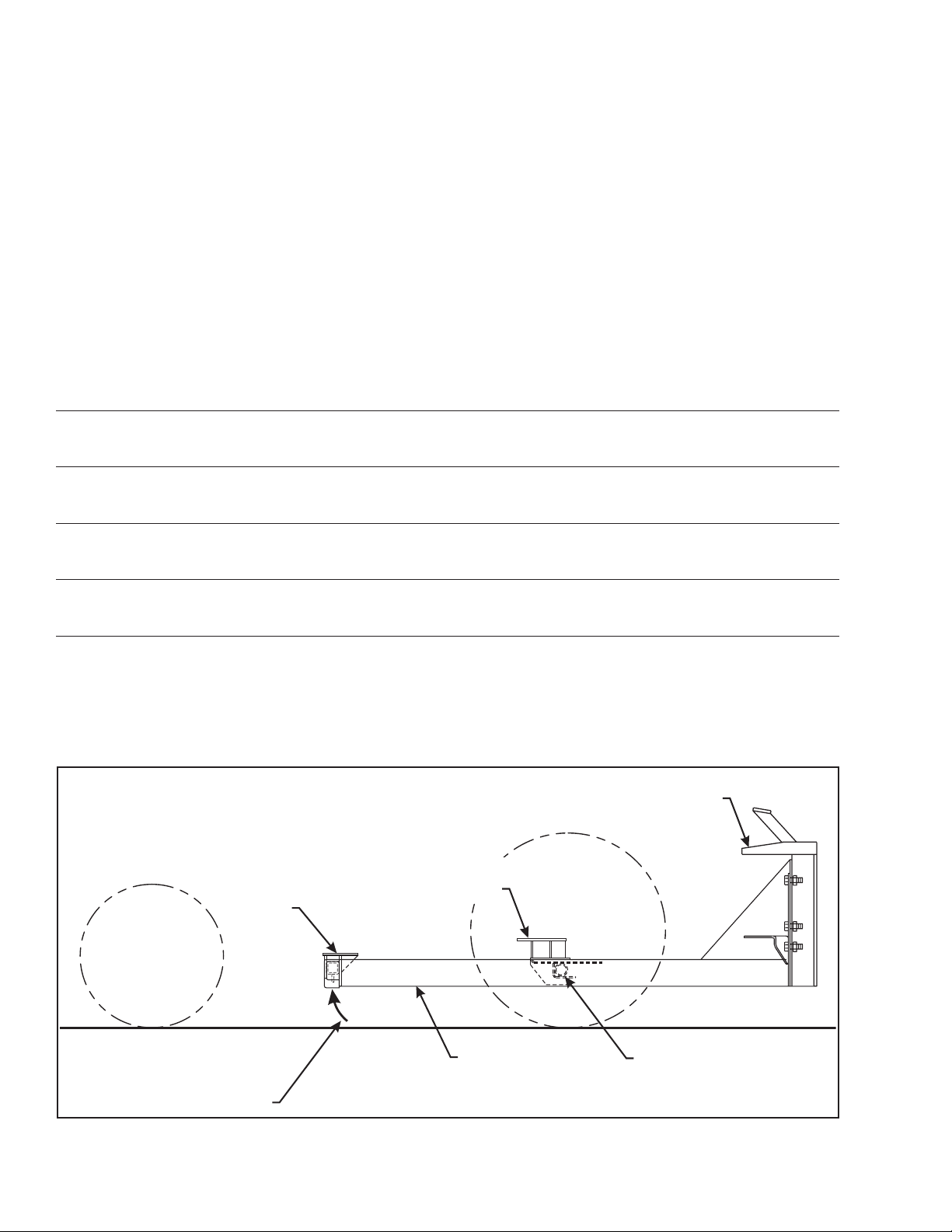

INSTALLING SUBFRAME TO BACKHOE (Figure 2)

Install subframe (1) to backhoe using 3/4 x 2" cap

screws (7) and 3/4" lock nuts (11)(Torque to 350 ft.·lbs.).

NOTE: If installing pump kit and subframe; spacers (13)

are required between subframe and backhoe.

INSTALLING MOUNTING BRACKETS

1. Temporarily remove drawbar from tractor hitch.

2. Remove six bolts which secure bottom of tractor

hitch to rear of tractor.

NOTE: Hitch will be held in place by two bolts at rear

of tractor.

3. Install rear mounting bracket (2) to rear of tractor

using 14mm x 45mm cap screws (6) and 9/16" lock

washers (10). Reattach draw bar and finish securing

rear bracket (2) to tractor hitch using 3/4 x 4" cap

screw (12) and lock nut (11).

4. Install front mounting bracket (8) to underside of

transmission casting using 12mm x 35mm cap

screws (5) and 1/2" lock washers.

5. Tighten all hardware to torques specified in General

Torque Specifications table.

REMOVING BACKHOE FROM PALLET

1. Install pump kit or hose kit. Refer to instructions

provided with kit for proper installation procedure.

Back tractor, parallel to subframe assembly, close to

backhoe.

CAUTION: Do not remove hardware

which secures backhoe to pallet until

bucket is installed. Backhoe may tip over

causing damage or serious personal

injury.

2. Remove stabilizers from shipping position. Install

stabilizers to backhoe using pins provided. Connect

stabilizer cylinders to stabilizers using pins provided.

3. Connect pump or hoses to tractor. Set bucket in

place below dipperstick. Remove boom lock pin and

carefully extend boom cylinder (lower boom) until

bucket can be connected to dipperstick.

4. Install bucket to dipperstick using pins, 3/8 x 2-1/2"

cap screws and 3/8" lock nuts provided. Carefully

extend bucket cylinder and connect bucket to four

bar link.

5. Install seat assembly to platform using 3/8" x 1-1/4"

cap screws and 3/8" lock nuts provided.

CAUTION: Do not fully extend boom or

dipperstick until backhoe is mounted to

tractor. Extending boom or dipperstick

may cause backhoe to tip over resulting in

damage to backhoe or serious personal

injury.

NOTE: Remove protective coating from cylinder

rods before operating backhoe controls.

6. Using backhoe hydraulics carefully lower stabilizers

and bucket to lift pallet off ground. Remove hardware

and slide pallet out of the way. Lower backhoe to

ground.

95 BACKHOE SUBFRAME

KUBOTA GRAND-L30 SERIES TRACTORS

MODEL ROPS CAB

L4630 X X

L5030 X X

Keep With Operator's Manual