User attention

If the contents of this manual do not consistent with the machine you use or have

any other questions, please contact your company immediately after sale.

Security related information

Most of the accidents related to operation operations, inspection, maintenance,

and repair operations are caused by basic negligent safety precautions and hazard

forecasts.

Accidents can be prevented in the bud by predicting dangerous

conditions. Therefore, attention must be paid to the location and type of danger. ( To

properly perform such operations, you must have the specified training, techniques,

and tools. )

Improper operation operation and improper inspection and maintenance

operations are very dangerous and will lead to personal injury accidents.

Please carefully read all the safety precautions, warnings and accident precautions

documented in this manual and machine and understand the contents until fully

mastered, otherwise absolutely not Ability of machine operation and inspection and

maintenance operations. If these warnings will cause personal casualties, be attention.

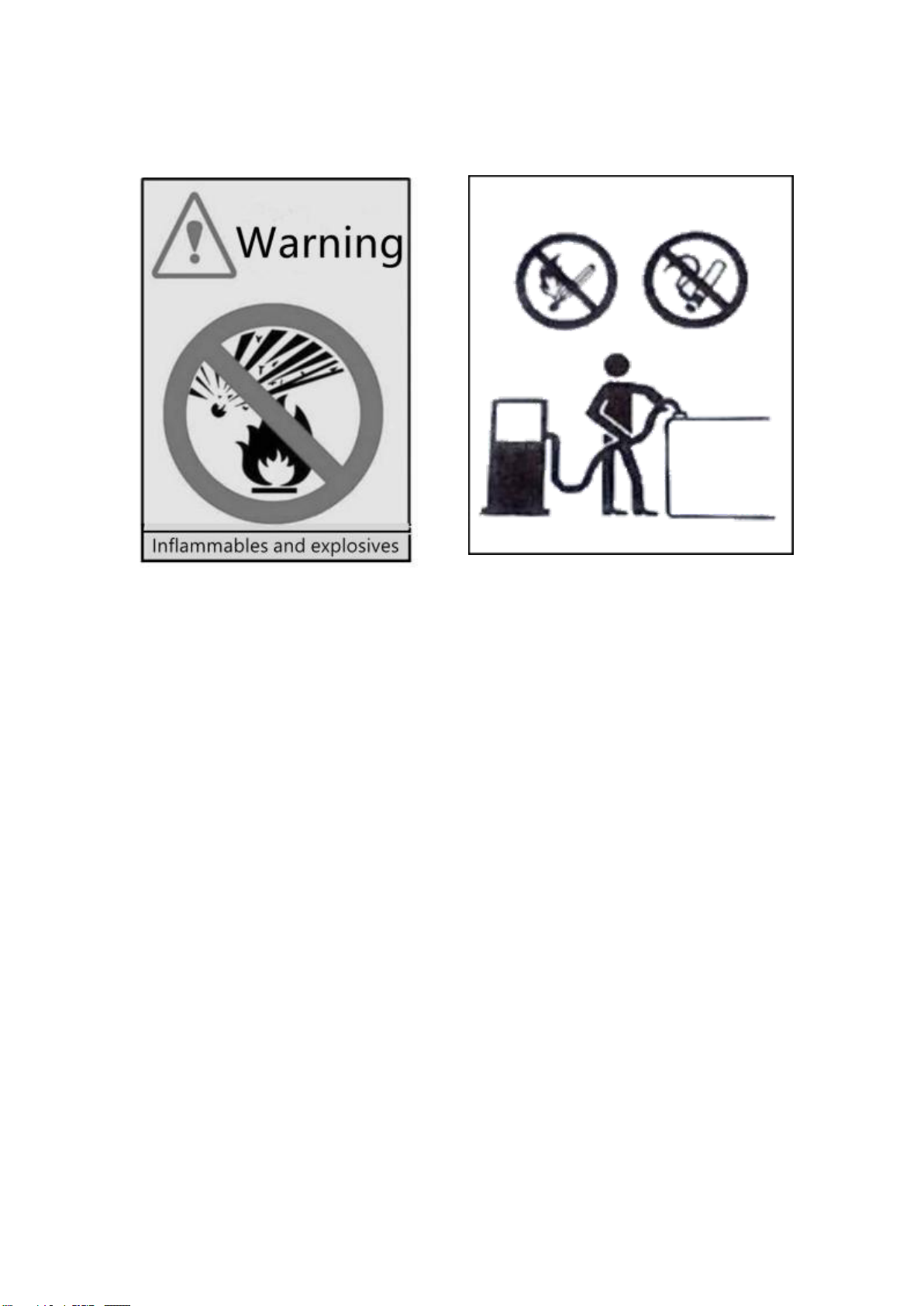

The safety tips of this manual, the safety signs used on this machine, distinguish

the extent of the possible hazards by the following warnings. Also includes

Prevention methods to avoid danger.

The Company cannot predict all hazards of operation, inspection and maintenance

in all environments. Therefore, the warnings indicated on this manual and this

machine do not cover all cases. If the operation, inspection and maintenance are not

involved in this manual, please consider the necessary safety precautions by

themselves. Users are personally responsible to take the necessary safety measures.

Safety Regarding proper maintenance and maintenance of the machine. The

recommendations are printed in the relevant sections of operation and maintenance in

this manual. Poor maintenance or maintenance steps are dangerous and can lead to

injury or death.Read and understand sections of operation and repair before any

maintenance or repair.

Maintenance personnel or technicians may not be familiar with many systems of

the machine, so special attention when performing services. When loading and

unloading any part.

It is important to have the knowledge of the system and components.

Many machines have parts size or weight, maintenance personnel or mechanics

can find information in this manual, and suitable cranes should be used when

removing any parts.

With.

The following are the basic things to note:

1 . All warnings, notices, and signs shall be read before operation, maintenance, or

repair.

2 . Wear goggles and feet when working around any part of the machine or any

accessory parts such as a crusher or a heavy hammer shoes. For welding work, wear

welding gloves, head covers, apron guards and other protective overalls as