6. Operation

6.1 Operation method

1. Pre-drill a pilot hole if the soil conditions are rocky, frozen, or too difficult to simply drive the post into the

ground.

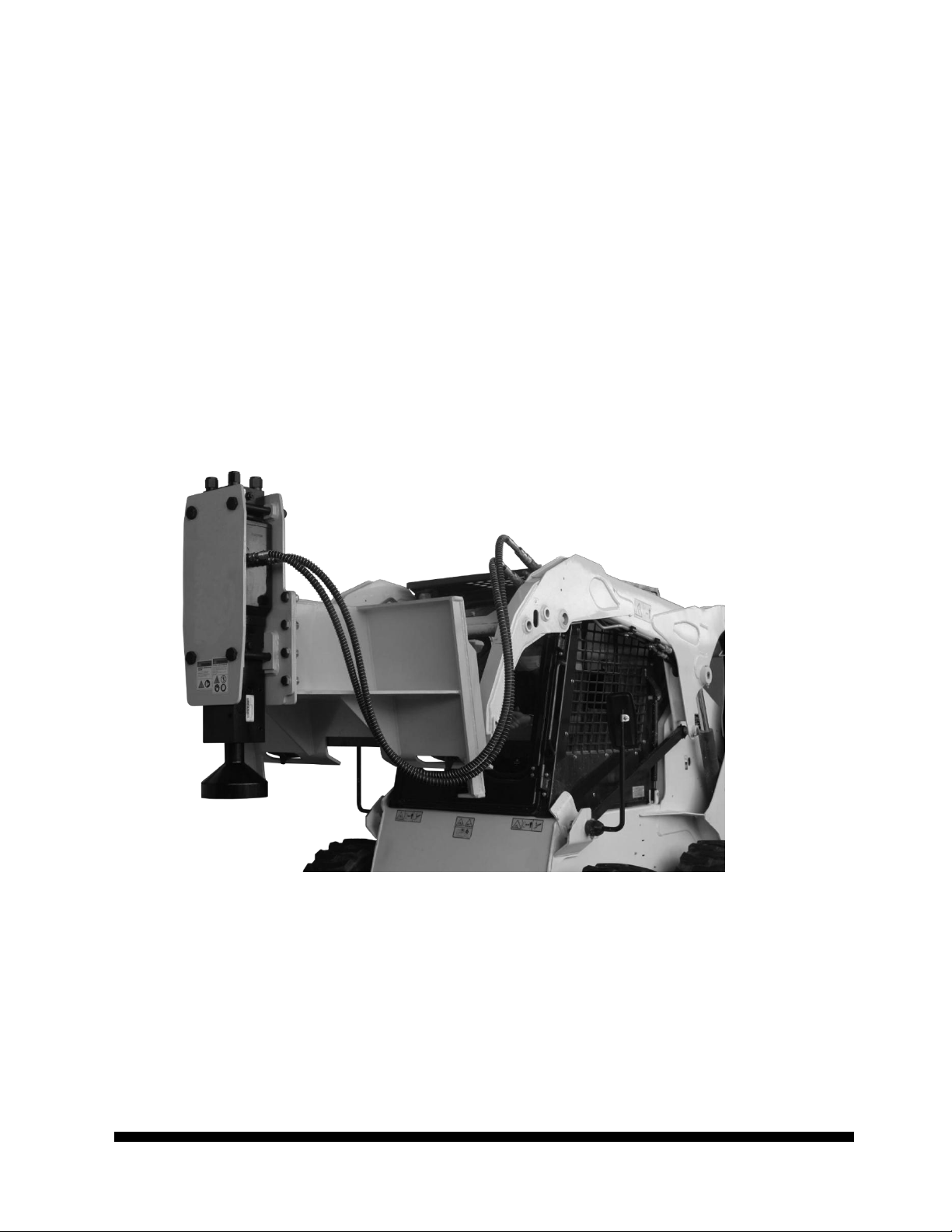

2. Requires another person to position the pile. This person will set the pile at the desired location and grasp the

pile securely.

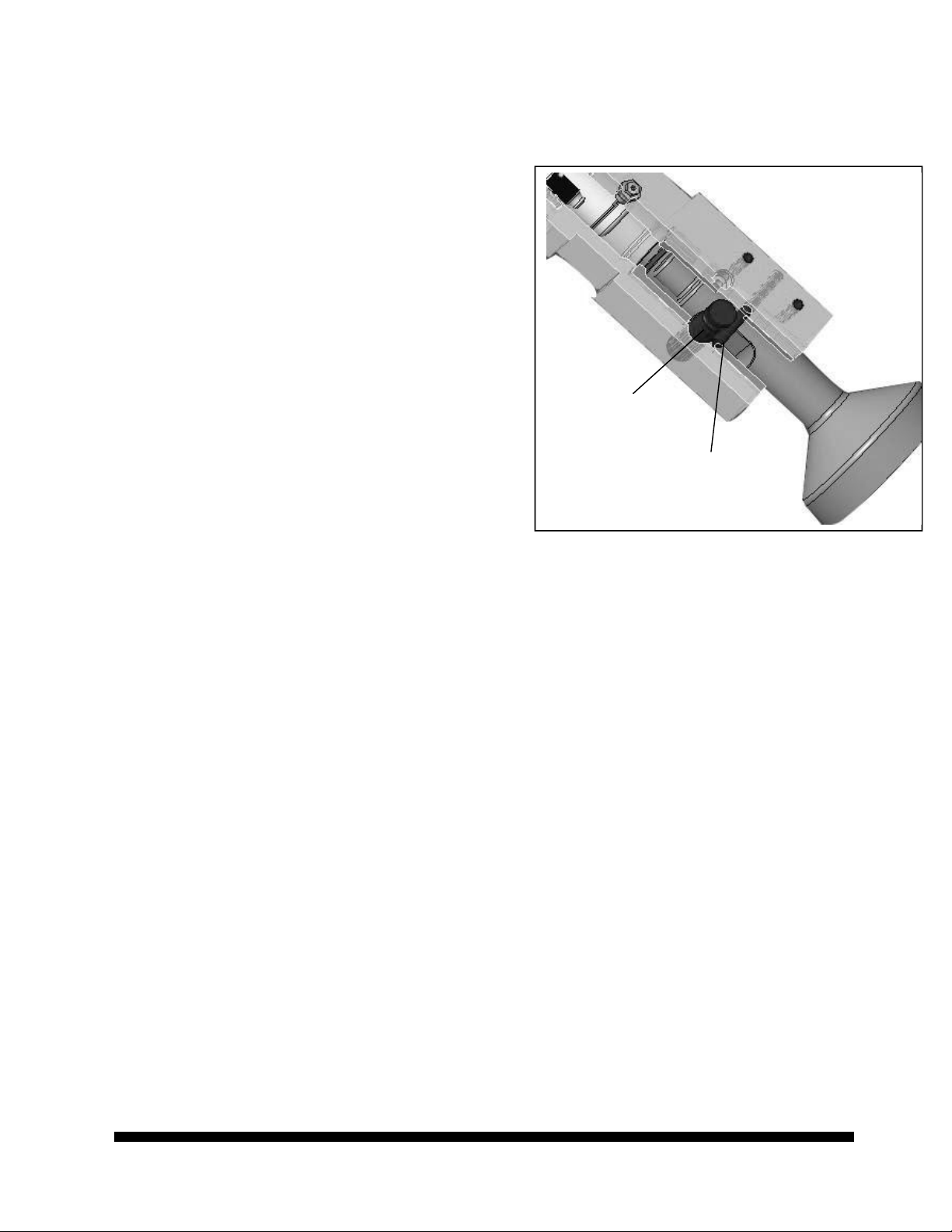

3. After the pile is in position, let the Driver onto the top of the pile, ensuring the pile is inside of the bottom portion

of the Driver, and continue lowering the driver until the weight of the Driver is supported by the pile.

After the pile is in position, the person who grasp the pile must leave vehicle as soon as possible.

Don't allow anyone stand under the attachments.

4. Move the vehicle slowly left, right, forward, or backward as needed until the pile is vertical to the ground.

5. The loader arms should be lowered as the pile is driven into the ground.

6. Drive the pile to the desired depth. Raise the Driver and move on to the next pile.

6.2 Operation Precautions

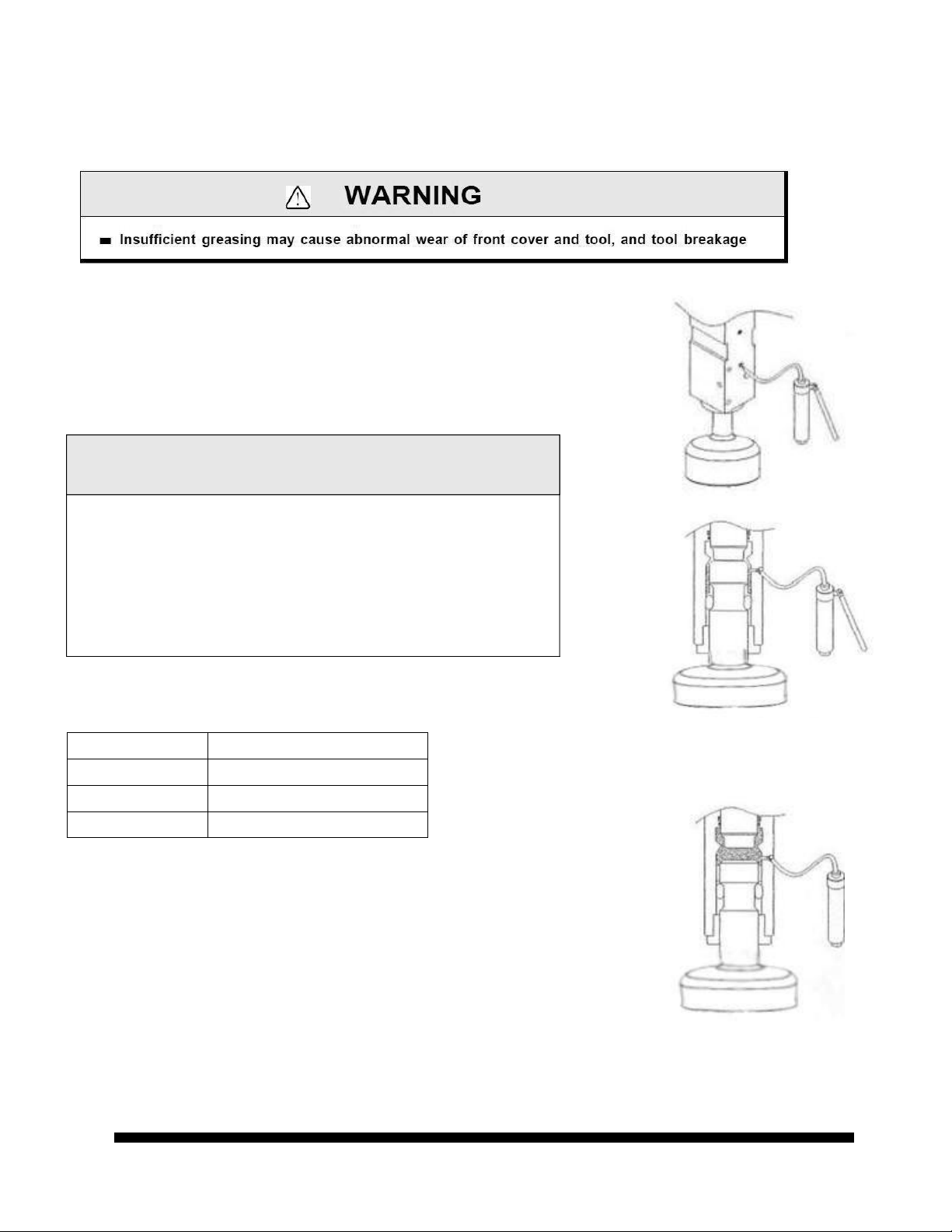

1) Stop operation as soon as hoses vibrate excessively.

Excessive vibration of high and low pressure hoses of the breaker calls for an instant disassembly and

repair.

Contact the nearest service station.

For caution’s sake, check oil leakage at the bank-head.

2) Avoid all blank hammering.

Continuous blank hammering will not only damage front head and loosen and break bolts,

but also adversely affect base machine.

Blank hammering occurs when proper position of the Tool is not applied to the Post driver hammer or

the Tool is used as a lever. (Sound changes during blank hammering.)

3) Operate the Post driver hammer at proper engine speed.

Driving the pile at the specified engine speed.

Raising engine speed more than necessary does not strengthen the force but increase oil temperature to the detriment of

the pistons and the valves.

sales@agrotkindustrial.com https://www.agrotkindustrial.com /