PREPARATION FOR INSTALLATION

SAFETY INSTRUCTIONS

To reduce the risk of fire, electric shock, or injury to persons, observe the following:

1. This range hood is for general ventilating use only. Do not use it to exhaust hazardous or

explosive materials or vapours.

2. This appliance must be installed by a qualified technician. The seller declines all

responsibility in case of failure to adhere to safety standards. Ensure that exhausted air

from this unit is not directed into flue that is used for venting fumes from other appliances.

3. Use this unit only in the manner intended by the manufacturer.

4. Before servicing or cleaning the unit, switch electric power off at central service panel and

lock service panel door so as to prevent power from being switched on accidentally.

When the power disconnecting means cannot be locked, securely fasten a prominent

warning device to the power service panel.

5. Installation work and electrical wiring must be done by qualified persons in accordance

with all applicable codes and standards, including fire-rated construction.

6. To prevent back drafting, sufficient air is needed for proper combustion and exhausting of

gases through the flue. Follow heating equipment guidelines and safety standards as

published by the local code authorities.

7. When cutting or drilling into any wall or ceiling, take precautions so as to not damage

electrical wiring.

8. Ducted ventilation must always be vented outside. Do not vent exhaust air into spaces

within walls, ceilings, attics, crawl spaces or garages.

9. Use only metal ductwork.

Install this hood in accordance with all requirements specified.

WARNING

This appliance requires a 120V 60 Hz electrical supply, and must be connected to an individual

properly grounded branch circuit, protected by a 15 or 20-ampere circuit breaker or time delay

fuse.

Two people are required for installation

Do not cut a joist or stud unless absolutely necessary. If a joist or stud must be cut then a

supporting frame must be constructed.

Before making cut-outs make sure there is proper clearance within the ceiling or wall for the

exhaust vent.

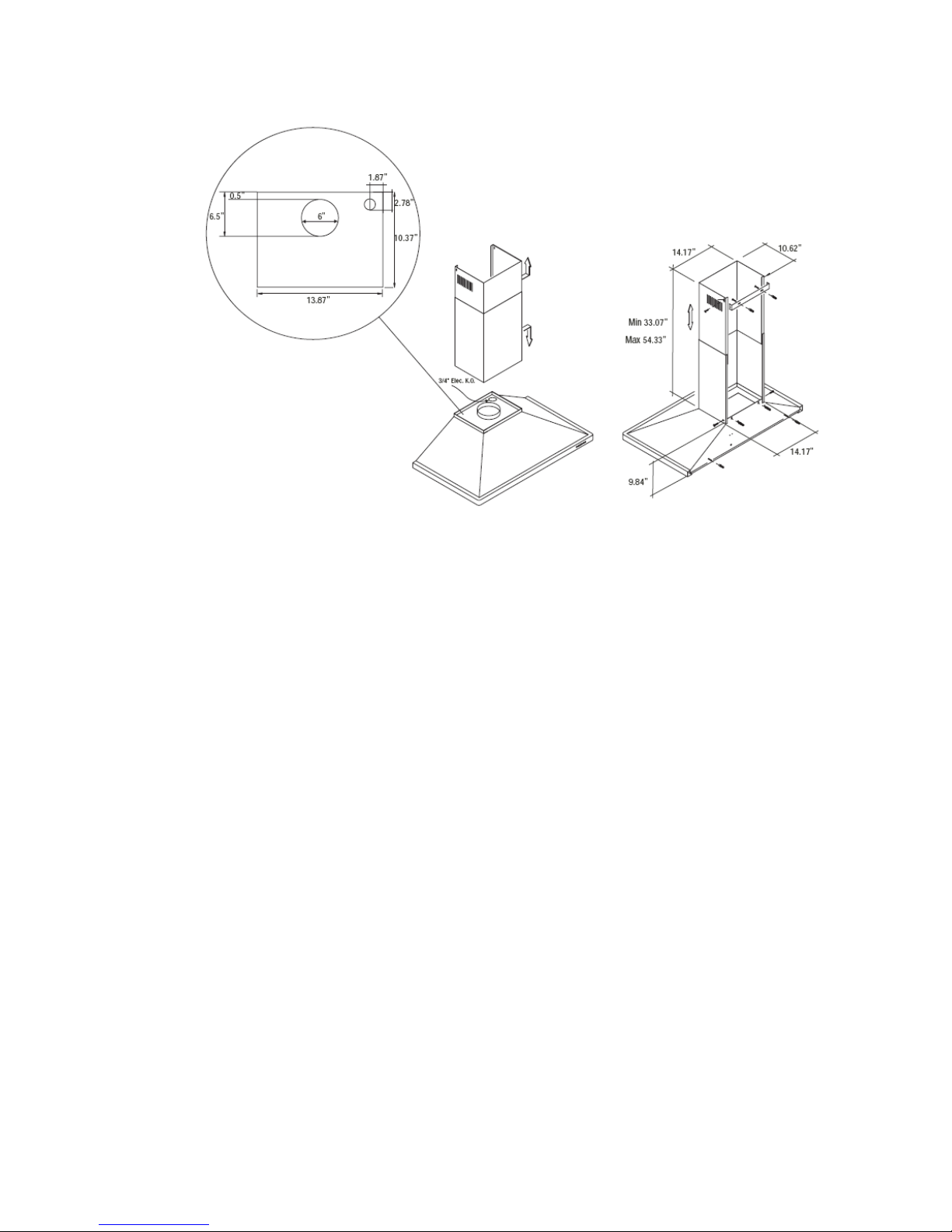

Check your ceiling height and the hood height maximum before you beginning installation of your

hood to ensure proper mounting height and clearance.