Thank you for choosing our

Barriquan

. Please read this Instruction Manual carefully before using this product

and keep this at hand whenever the operator can read. If you have any questions on about this product or in this

manual, please feel free to contact us at your nearest office.

1.For Your Safety

For operating this product safely, please read

cautions in this Instruction Manual thoroughly and

understand them enough before using「

Barriquan

」.

There are “safety alert marks”in this manual and it’s

represented as 「Cautions」. This symbol is used to

call your attention to items or operation that should be

cautious.

2.Specification

Barriquan

is a tool holder for deburring which has a

floating structure extendable within the range 10 mm.

By this floating structure, the cutter edge can move

automatically along the workpiece shape and deburr.

Besides, this has another structure which is able to

adjust Spring Pre-load depending on the burr.

3.Method of Use

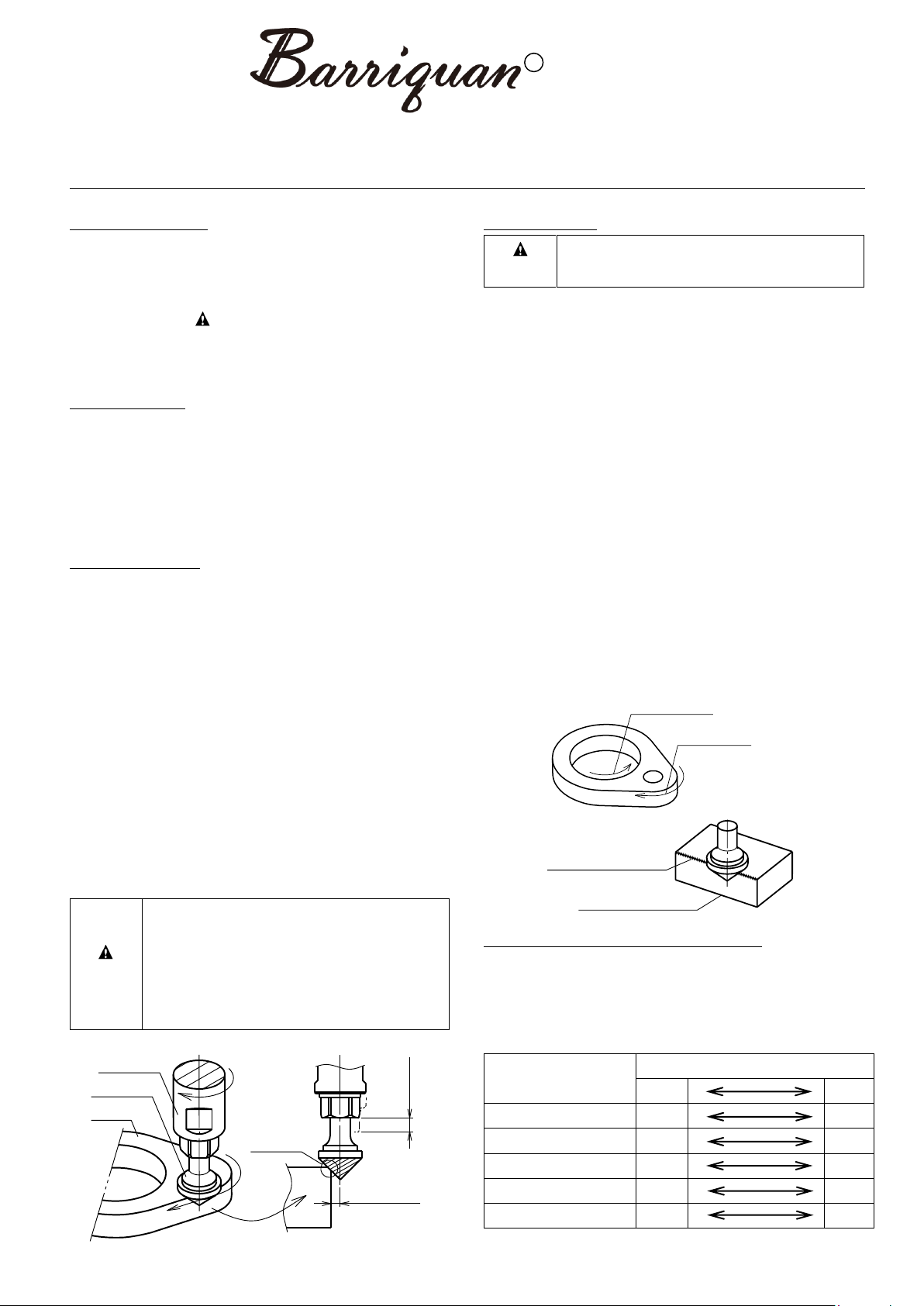

Attach Cutter to φ6 Collet. (Spanner size [nominal]:

10 mm, 13mm) Fastening torque of Collet is 12N・m.

Offset this tool about half of Cutter radius as Cutter

taper center can contact the burred part of workpiece.

And then, use this tool compressing Cutter about 1~

5mm (Figure1). Processing Parameter in Figure 1 will

be changed depending on the chosen Cutter. Please

set the suitable parameter for the attached Cutter.

The maximum number of rotation is 5000min-1. Please

do not over this maximum when using this tool.

Please test the workpiece as a trial at first and then

process them continually. At the trial test, start the

process low parameter (Pre-load and compression

amount) and then try gradually higher parameter to

achieve the requested finish. Please refer to “3-2.

Adjustment for Processing Parameter”.

At the trial test, start the process low

parameter (Pre-load and compression

amount) and then try gradually higher

parameter to achieve the requested

finish. If the parameter is excessive, the

floating structure may not work and it

leads to the tool broken soon.

3-1.Cautions

Please use this holder normal rotation. If

using this reverse rotation, Collet may be

loosened and it may cause the tool broken.

For deburring, please use it by Down-Cut. (Figure 2)

This tool holder is for the front side surface of workpiece.

This cannot be used for the backside surface to deburr.

(Figure 3)

When measuring Cutter projection, etc., please check if

Collet is projected max. length from Stem If pre-load is

weak, Collet may be retracted. In that case, please

increase pre-load.

This tool does not have a floating structure for radial

direction. Do not choose Cutter and Cutting method

which give excessive load to the directions except axial

direction.

When using cutting fluid, do not pour it to

Barriquan

directly. If the fluid comes inside the tool, it may lead the

malfunction.

Rotate the tool and deburr along workpiece shape. (Do

not use this without tool rotation.) If using without tool

rotation, floating function does not work and it may lead

to the tool broken.

When attaching this product to tool holder, etc., please

do not tighten this too much. In case of excessive

fastening, this tool may not work properly.

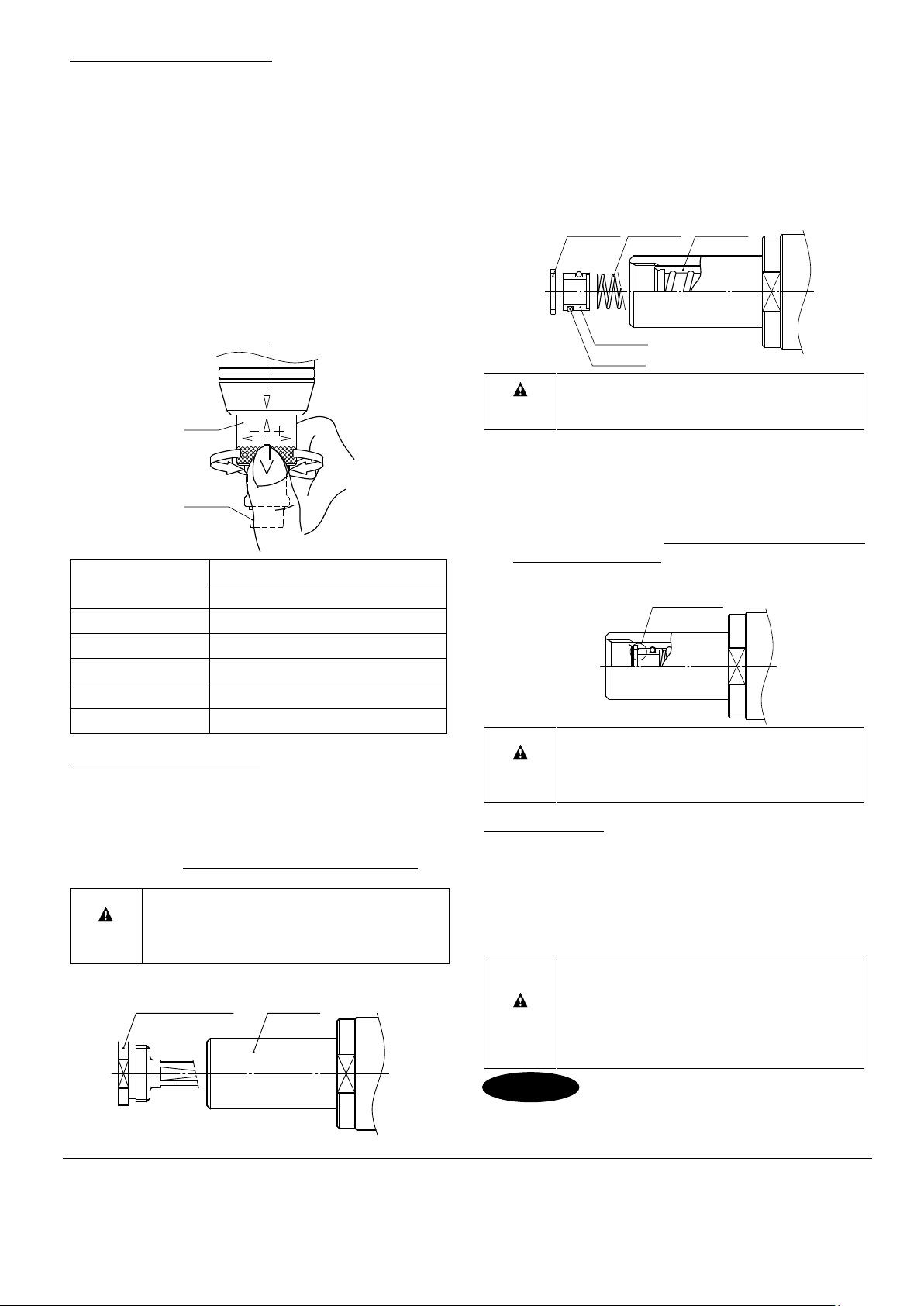

3-2.Adjustment for Cutting Amount

For adjustment of cutting amount, please refer to

the below chart and adjust the processing parameter.

When making cutting amount bigger, please increase

it gradually. For Spring pre-load, please refer to “4.

Adjustment for Spring Pre-load”.

Offset length

1/2 Cutter Radius

Counter-clockwise for inner edge

Available for front side burr

Non-available for backside burr

(example of 90°Cutter use)