B. General information

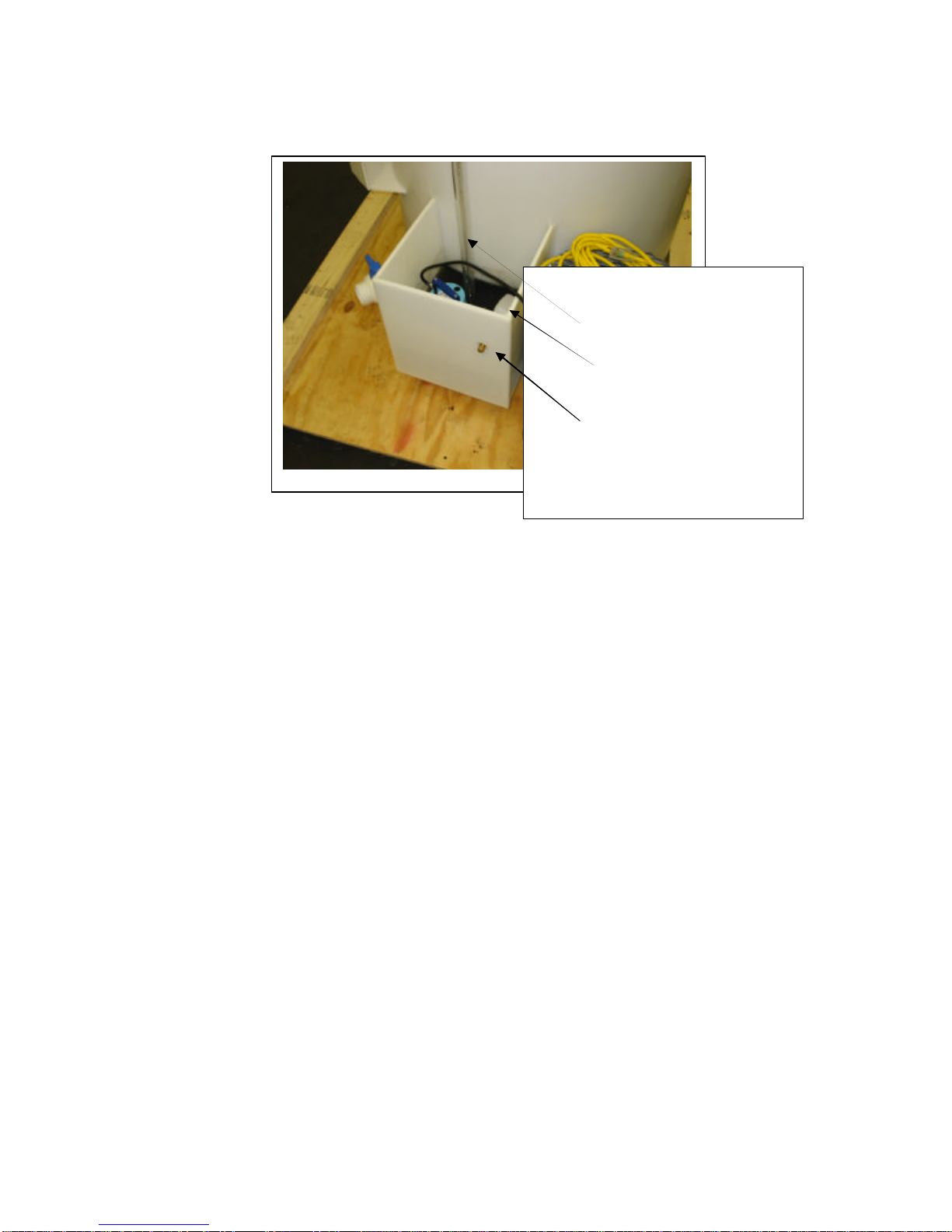

Your CAP™ Clean Air Plant (CAP) consists of:

•A fan housing, consisting of a fanmotor, fan, an air distribution manifold, fittings, a control valve, and ducts,

•A BioStack®cartridge with BioOx®enzymes installed,

•A submersible water pump with 120 V three-pronged plug,

•A water reservoir with float level control for the water, and

•An automatic water feed ¼” FNPT.

Additionally, BioOx®enzymes have been included with your CAP prior to shipping. Use only BioOx®enzymes,

supplied by Air & Water Solutions, Inc., in your CAP™ Clean Air Plant.

How it works:

The CAP is an air cleaning unit, which biologically oxidizes organic chemicals and toxic gases and removes dusts

and other particles from the air. This unit is specially designed for the reduction of air pollutants and solid

particles generated by industrial operations. The CAP has been loaded with BioOx®enzymes (biomass)

which are able to eliminate a broad spectrum of contaminants by biological digestion.

In order for the CAP to operate efficiently, it must be provided with water and oxygen for biological oxidation to

take place. Oxygen is sufficiently supplied from the contaminated air stream, drawn in by the fan. Water is injected

into the cartridge, continuously washing the unit. The solids settle and the water is re-used by recirculation from the

pump inside the reservoir, back into the cartridge.

While the CAP is operating, the amount of water is gradually reduced by evaporation due to heating from pump

operation, dry air from outside, and heat generation from the oxidation of pollutants. Because of this loss of water,

you must supply water to the CAP periodically.

C. Installation

Find a proper place to install the CAP. It should be:

•In a good location to draw in the contaminated stream, to capture it as close to the source as convenient.

•Away from frequent movements of people and vehicles.

•Away from dangerous, hot, or flammable sources.

•Secured to a solid support if necessary to prevent accidental knockdown.

•Convenient to a water source. NOTE IF INSTALLING WATER LEVEL CONTROL FLOAT SWITCH:

always inspect water level control float switch for proper operation. Mechanical float switches sometimes may

fail in the open position. A malfunction could cause flooding! Turn off water inlet line when not in use. Limit the

total amount of water available to the float switch by using a separate tank, or place a safety shutdown

mechanism if prevention of water leakage is critical.

•Easily accessible for maintenance and draining.