Important Safety Instructions

When operating any electrical appliance, basic precautions should always be fol-

lowed for safety.

RISK OF FIRE, ELECTRIC SHOCK, OR INJURY

• Carefully read the entire contents of this manual.

• Do not use outdoors, in moist areas or on wet surfaces.

• Do not use the unit in areas of extreme heat or in the pres-

ence of ammable gas.

• Do not allow any foreign objects to enter the ballast cooling

vents.

• Do not attempt to service or repair the unit yourself. Any

attempt to repair the unit yourself could cause serious injury

and will void the warranty.

• Do not handle the plug or appliance with wet hands.

• Do not pull on power cord to unplug. To unplug grasp the plug, not the cord.

• Do not use with damaged power cord or plug. If appliance is not working prop-

erly, has been dropped, damaged, left outdoors, or dropped into water, call a

customer service representative at 1-877-424-7326.

WARNING: RISK OF ELECTRICAL SHOCK. CAN CAUSE INJURY OR DEATH.

UNPLUG OR DISCONNECT UNIT FROM POWER SUPPLY BEFORE SERVICING.

Store and transport -4˚ F ~ 180˚ F, humidity 10% ~ 90% (Non Condensing).

Do not operate unit in ambient temperatures above 150˚ F.

KEEP OUT OF REACH OF CHILDREN

Only use the power adapters included with the purication system.

WARNING: UV LIGHT HAZARD.

Harmful to skin and eyes. Can cause

temporary or permanent loss of vision.

Never look at the lamp while illuminated.

To prevent exposure to ultraviolet light,

be sure the power is disconnected until

installation is completed and before ser-

vicing.

UV lamps contain Hg (Mercury).

High or long term exposure to Hg can lead to serious health risks. UV lamps should

be disposed of according to disposal laws in your area. UV lamps should never

be disposed via standard waste receptacles. They often break when thrown into a

dumpster, trash can or compactor, or when they end up in a landll or incinerator.

Learn more about proper disposal methods and nd disposal centers at www.

earth911.org.

Never touch UV lamp with bare hands. Oils from your skin can create hot

spots causing UV lamp to break when illuminated.

Never remove the outer housing of any components.

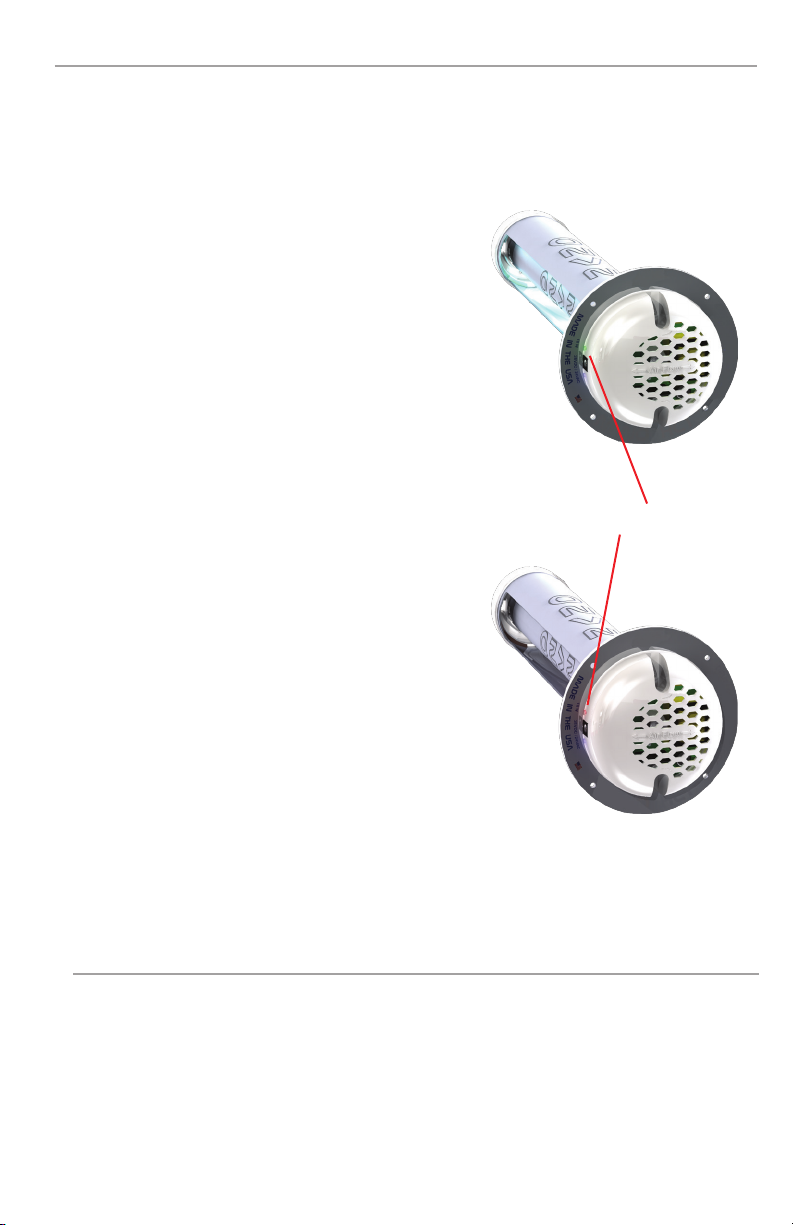

Cooling Vents

WARNING

OPTICAL RADIATION EXPOSURE HAZARD

DO NOT ATTEMPT TO OPERATE UNIT WITHOUT

PROPERLY INSTALLING UNIT FIRST.

PERMANENT EYE AND SKIN DAMAGE MAY RESULT.

1