OAM II APPLICATION GUIDE

Air Monitor Corporation 800.AIR.FLOW Page 2 onicon.com

0

500

0.000 0.500 1.000 1.500 2.000 2.500

Total Pressure Drop In wc

Required Fixed Inlet Total Pressure Drop Graph

1.00(25.40)

.90(22.86)

.80(20.32)

.70(17.78)

.60(15.24)

.50(12.70)

.10(2.54)

.09(2.29)

.08(2.03)

.07(1.78)

.06(1.52)

.40(10.16)

.30(7.62)

.20(5.08)

.05(1.27)

.04(1.02)

.03(.76)

.02(.51)

.01(.25)

100 (30)

200 (61)

300 (91)

400 (122)

500 (152)

600 (183)

700 (213)

800 (244)

900 (274)

1000 (305)

2000 (610)

3000 (914)

4000 (1219)

5000 (1524)

6000 (1829)

7000 (2134)

8000 (2438)

9000 (2743)

10,000 (3048)

INTAKE

EXHAUST

Air Velocity in feet and (meters) per minute through Free Area

Ratings do not include the effect of a bird screen

Static Pressure Drop in inches w.g. and (mm)

Example of a louver pressure drop graph

Blowing dust and debris, moist air and low ow velocities are just some of the

problems commonly associated with outdoor airow measurement. These

conditions can be very challenging when trying to accurately measure the

amount of outdoor air entering a building using thermal or Pitot style airow

elements. Air Monitor’s OAM II Outdoor Airow Measurement System is

specically designed to provide accurate airow measurement in this

challenging application.

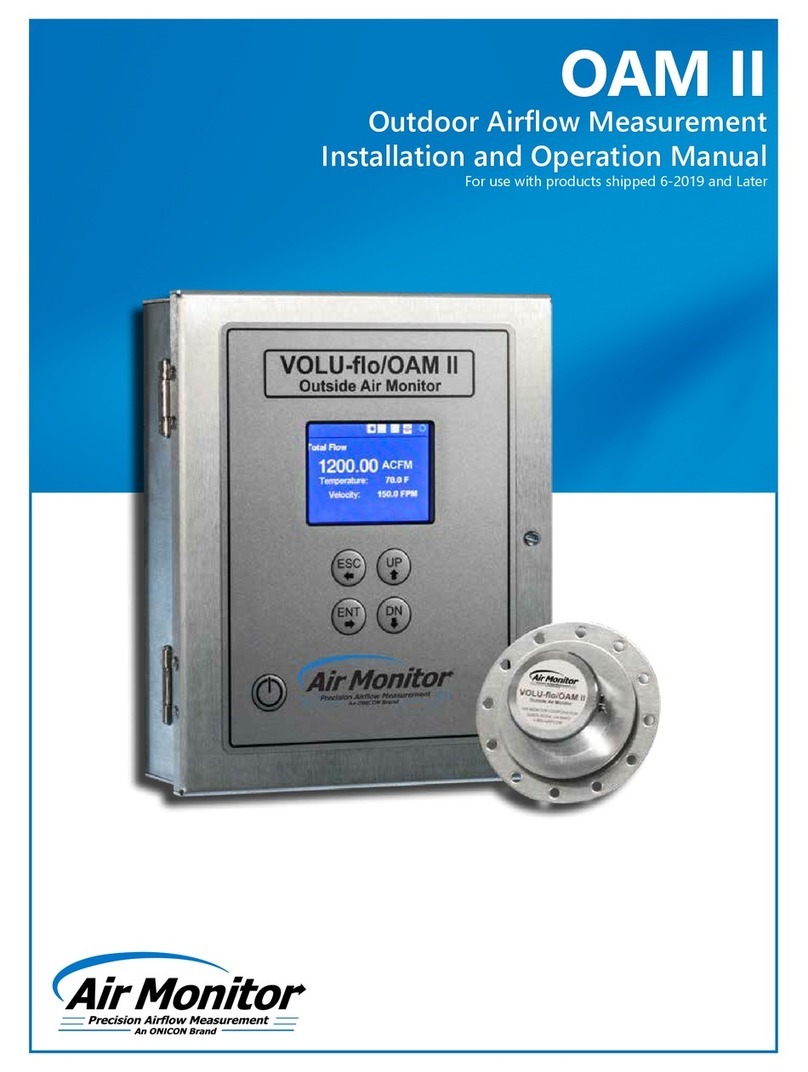

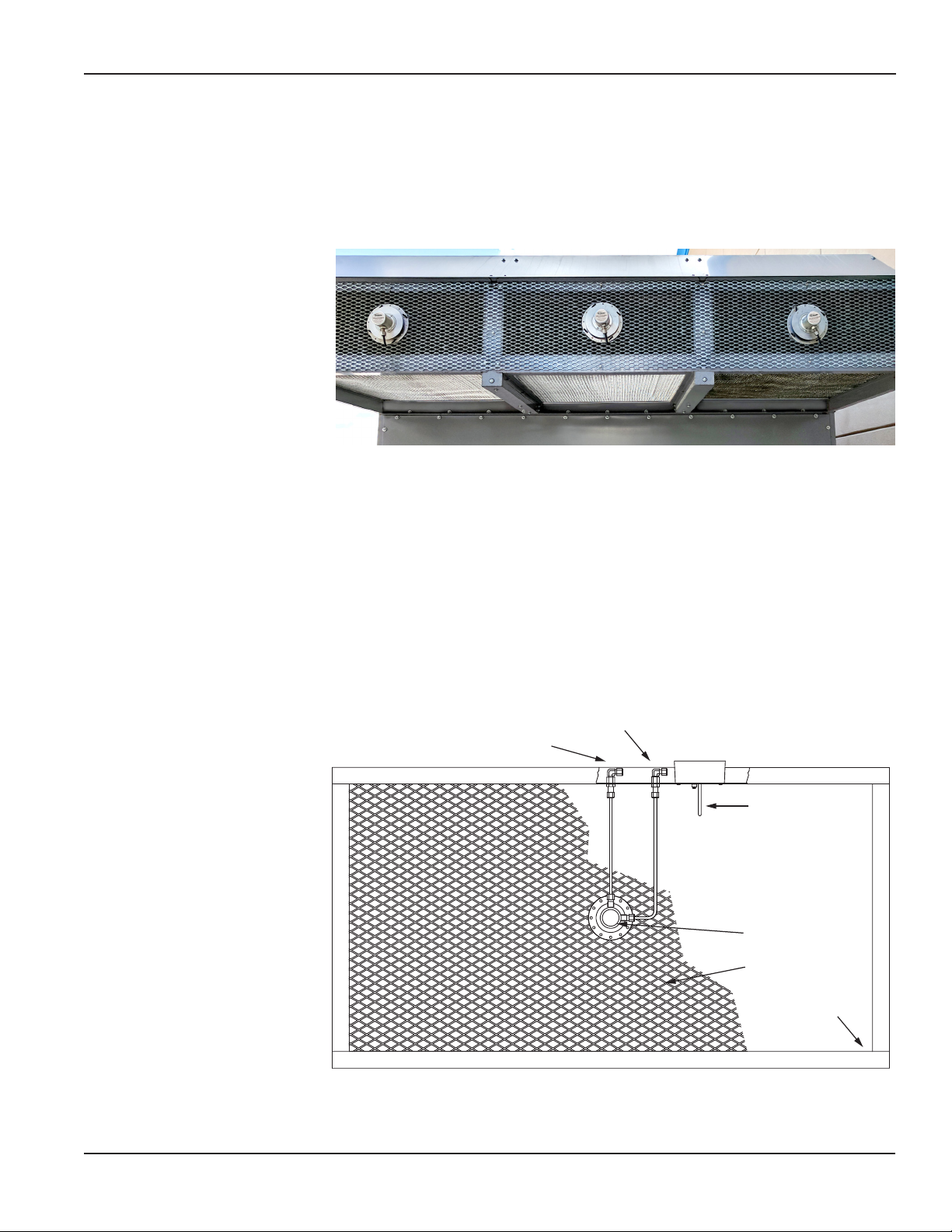

Each OAM II consists of a dedicated transmitter with a built-in barometric

pressure sensor, reference temperature sensor(s) and uni-sensor ow element(s).

The system oers exceptional performance in this dicult but extremely

important airow measurement application.

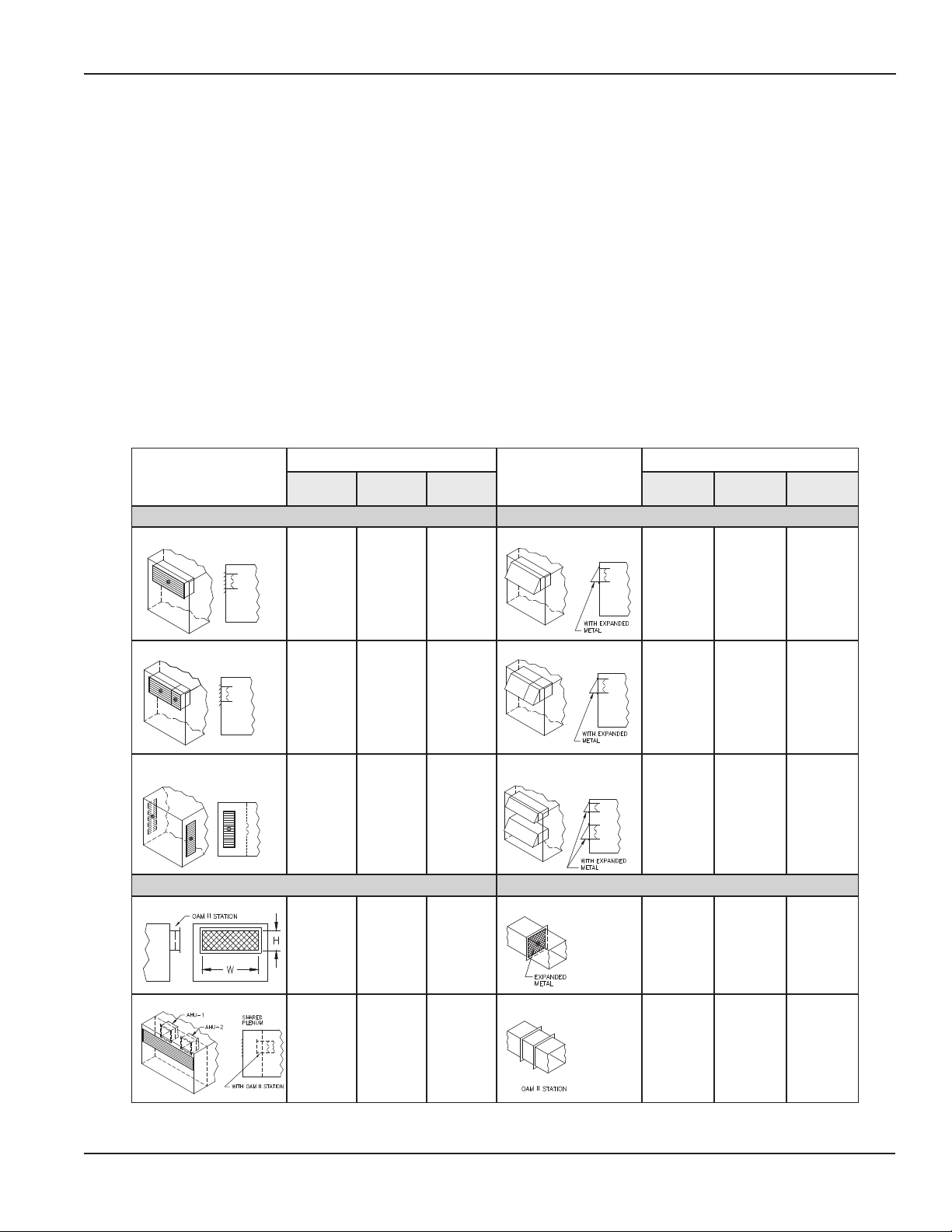

There are three dierent OAM II congurations. Each oers distinct advantages

for some of the most common outdoor airow applications. This guide

presents an overview of airow inlet types, OAM II congurations, and system

components. Consider the following when selecting an outdoor airow

measurement system.

What is the airow inlet type?

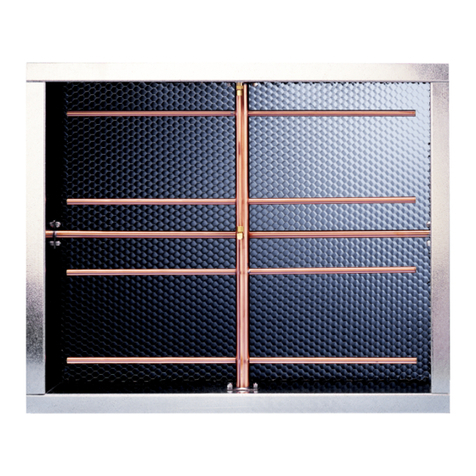

There are a variety of inlet types. The most common inlets incorporate

architectural louvers or packaged roof top units with single or multiple rain

hoods. The OAM II utilizes the static dierential pressure eld created by the air

entering and moving through the xed inlet. The dierential pressure required

to achieve accurate airow measurement is indicated in the graph below. Refer

to the louver manufacturer’s published pressure drop data to conrm it is

adequate to meet your application requirements.

What is the airow inlet size/geometry?

Many systems are large enough or shaped such that they will require multiple

uni-sensors connected in parallel to eectively average total airow through

the inlet. Minimum/Economizer (split) inlets may also require multiple sensors.

What is the best OAM II conguration for my applications?

The OAM II is available in three dierent factory congurations based on your

inlet type. Each conguration is optimized for a specic airow application. A

detailed description of each conguration is provided on the next page.

SECTION 1.0

INTRODUCTION