NF FRA5014 User manual

NF Corporation

SERVO ANALYZER

FRA5014

Instruction Manual

SERVO ANALYZER

FRA5014

Instruction Manual

DA00019832-004

Registered Trademarks

National Instruments is a trademark of National Instruments Corporation in U.S.A.

Lantronix is a trademark of Lantronix, Inc. in U.S.A.

Other company or product names are generally trademarks or registered trademarks of the

company to which each relates.

FRA5014

i

⎯Preface ⎯

Thank you for purchasing the FRA5014 Servo Analyzer.

To ensure safe and proper use of this electric equipment, please read first Safety Precautions on the

following pages.

⚫Caution Symbols Used in This Manual

The following caution symbols are used in this manual. Be sure to observe these caution symbols and

their contents to ensure the safety of the user and avoid damage to the equipment.

This symbol indicates information for the avoidance of a hazard such as electric shock that may

endanger human life or cause injury during handling of the equipment.

This symbol indicates information for the avoidance of damage to the equipment during handling.

⚫This manual has the following chapter organization.

If reading this manual for the first time, start from 1. OVERVIEW.

1. OVERVIEW

Briefly describes and explains the features, applications, and functions as well as brief

operation principles of the FRA5014.

2. PREPARATIONS BEFORE USE

Describes various cautions regarding preparations to be made before using the FRA5014,

ranging from installation to connection of the power supply.

3. PANEL AND BASIC OPERATIONS

Describes the functions and actions of the panel controls and their basic operations. Read

this chapter while operating the FRA5014.

4. ADVANCED OPERATIONS

Describes how to use advanced functions.

5. REMOTE CONTROL

Describes remote control via GPIB, USB, or RS-232.

6. TROUBLESHOOTING

Describes error messages and handlings when problems occur.

7. MAINTENANCE

Describes how to store, re-pack, and transport the FRA5014 and how to conduct the

performance test.

8. SPECIFICATIONS

Lists the specifications (functions and performance) of the FRA5014.

!

CAUTION

!

WARNING

FRA5014

ii

⎯Safety Precautions ⎯

To ensure safe use, be sure to observe the following warnings and cautions.

NF Corporation shall not be held liable for damages that arise from a failure to observe these warnings

and cautions.

This product is a Class 1 product (with protective conductor terminal) that conforms to the JIS and IEC

insulation standards.

⚫Be sure to observe the contents of this instruction manual.

This instruction manual contains information for the safe operation and use of this product.

Be sure to read this information first before using this product.

All the warning items contained in this instruction manual are intended for preventing risks that may

lead to serious accidents. Ensure to obey them.

⚫Be sure to ground the product.

This product uses a line filter, which may cause electric shock if the product is not grounded.

To prevent electric shock accidents, connect it to an earth ground so that ground resistance is 100Ω

or less.

⚫Check the power supply voltage.

This product operates on the power supply voltage indicated in Grounding and Power Supply

Connection in this instruction manual.

Prior to connecting the power supply, check that the voltage of the power outlet matches the rated

power supply of the product.

⚫In case of suspected anomaly

If this product emits smoke, an abnormal smell, or abnormal noise, immediately power it off and

stop using it.

If such an abnormal occurs, prevent anyone from using this product until it has been repaired, and

immediately report the problem to NF Corporation or one of our representatives.

⚫Do not use this product when gas is present.

An explosion or other such hazard may result.

⚫Do not remove the cover.

This product contains high-voltage parts. Absolutely never remove its cover.

Even when the inside of this product needs to be inspected, do not touch the inside. All such

inspections are to be performed by service technicians designated by NF Corporation.

⚫Do not modify this product.

Never modify or try to modify the instrument. Your modification of the instrument could cause

unexpected accidents or failures. NF Corporation has the right to refuse providing services for any

instruments modified by unauthorized persons.

⚫Do not expose this product to water.

When this product is used in wet condition, it may cause an electric shock and a fire. If this product

is exposed to water, unplug the mains supply cord immediately, and contact NF Corporation or one

of our representatives.

Safety Precautions

FRA5014

iii

!

!

⚫If lightning occurs, power off this product and unplug the mains supply cord.

A lightning may cause an electric shock, a fire and a failure.

⚫Safety-related symbols

The general definitions of the safety-related symbols used on this product and in the instruction

manual are provided below.

Instruction Manual Reference Symbol

This symbol is displayed to alert the user to potential danger and refer

him/her to the instruction manual.

Electric Shock Danger Symbol

This symbol indicates locations that present a risk of electric shock under

specific conditions.

Warning Symbol

This symbol indicates information for avoiding danger to human life or bodily

injury while handling this product.

Caution Symbol

This symbol indicates information for preventing damage to the product when

handling it.

⚫Other symbols

This symbol indicates the “on” position of the power switch.

This symbol indicates the “off” position of the power switch.

This symbol indicates when connected to the case.

This symbol indicates when connected to the ground.

⚫Waste disposal

To help ensure environmental protection, please note the following

precaution regarding disposal of this product.

•This product contains a lithium battery.

!

CAUTION

WARNING

FRA5014

iv

Contents

Page

1. OVERVIEW....................................................................................................................1-1

1.1 Features.................................................................................................................1-2

1.2 Applications............................................................................................................1-2

1.3 List of Functions.....................................................................................................1-3

1.4 Operation Principles...............................................................................................1-5

2. PREPARATIONS BEFORE USE ...................................................................................2-1

2.1 Checking Before Use .............................................................................................2-2

2.2 Installation..............................................................................................................2-3

2.2.1 General precautions for installation ................................................................2-3

2.2.2 Installation conditions......................................................................................2-3

2.2.3 Rack mount .....................................................................................................2-4

2.3 Grounding and Power Supply Connections ...........................................................2-9

2.4 Simple Operation Checks.....................................................................................2-10

2.5 Calibration............................................................................................................2-11

3. PANEL AND BASIC OPERATIONS ...............................................................................3-1

3.1 Panel Components and Operations .......................................................................3-2

3.2 Display and Initial Settings at Power-on ................................................................3-4

3.2.1 Checks before turning power on .....................................................................3-4

3.2.2 Display at power-on ........................................................................................3-5

3.2.3 Initial Settings..................................................................................................3-5

3.3 I/O Terminals..........................................................................................................3-7

3.3.1 Oscillator’s output terminal..............................................................................3-7

3.3.2 Analyzer’s input terminals ...............................................................................3-8

3.3.3 Isolation of signal terminals.............................................................................3-9

3.4 I/O Connections....................................................................................................3-10

3.5 Basic Operations..................................................................................................3-11

3.5.1 Sweep measurements...................................................................................3-11

3.5.2 Spot measurements ......................................................................................3-12

3.5.3 Measurement values during overload input ..................................................3-12

4. ADVANCED OPERATIONS ...........................................................................................4-1

4.1 Accept/Reject Criteria ............................................................................................4-2

4.1.1 Accept/reject range settings............................................................................4-2

4.2 Servo System Measurements ................................................................................4-3

5. REMOTE CONTROL .....................................................................................................5-1

5.1 Preparations for Use ..............................................................................................5-2

5.1.1 USB setup .......................................................................................................5-2

5.1.2 GPIB setup......................................................................................................5-2

5.1.3 RS-232 setup ..................................................................................................5-3

5.1.4 Selection of remote control interface ..............................................................5-4

Contents

FRA5014

v

5.1.5 Identification of USB devices ..........................................................................5-5

5.1.6 GPIB address setting ......................................................................................5-5

5.1.7 GPIB use precautions .....................................................................................5-6

5.2 Command Lists ......................................................................................................5-7

5.3 Command Tree.....................................................................................................5-11

5.4 Command Descriptions........................................................................................5-12

5.4.1 Overview of programming language .............................................................5-12

5.4.2 Detailed description of commands................................................................5-13

5.5 Status System ......................................................................................................5-29

5.5.1 Overview of status system ............................................................................5-29

5.5.2 Status byte ....................................................................................................5-30

5.5.3 Standard event status ...................................................................................5-31

5.5.4 Operation status............................................................................................5-33

5.5.5 Overload status.............................................................................................5-35

5.6 Cautions for Programming ...................................................................................5-36

6. TROUBLESHOOTING...................................................................................................6-1

6.1 Error Displays.........................................................................................................6-2

6.1.1 Error at power-on ............................................................................................6-2

6.1.2 Remote control errors .....................................................................................6-3

6.2 Troubleshooting......................................................................................................6-4

7. MAINTENANCE.............................................................................................................7-1

7.1 Introduction ............................................................................................................7-2

7.2 Routine Checks......................................................................................................7-2

7.3 Storage, Repackaging, and Shipping.....................................................................7-2

7.4 Checking the Version Number................................................................................7-3

7.5 Checking Isolation..................................................................................................7-3

7.6 Checking Oscillator’s Output Waveform.................................................................7-3

7.7 Performance Test ...................................................................................................7-3

7.7.1 Frequency accuracy test .................................................................................7-4

7.7.2 Oscillator AC amplitude accuracy test.............................................................7-4

7.7.3 Oscillator DC bias accuracy test .....................................................................7-4

7.7.4 Ratio accuracy test..........................................................................................7-5

7.7.5 IMRR test ........................................................................................................7-6

7.7.6 Dynamic range test .........................................................................................7-7

7.8 Calibration..............................................................................................................7-7

8. SPECIFICATIONS .........................................................................................................8-1

8.1 Oscillator Block ......................................................................................................8-2

8.2 Analyzer Input Block ..............................................................................................8-3

8.3 Analysis Processing Block .....................................................................................8-4

8.4 Measurement Processing Block.............................................................................8-4

8.5 Setting Memory ......................................................................................................8-4

8.6 Remote Control Interface .......................................................................................8-5

FRA5014

vii

Figures and Tables

Page

Figure 1-1. Block Diagram.................................................................................................1-5

Figure 2-1. Dimensions of Rack Mount (mm Based Rack) ...............................................2-5

Figure 2-2. Dimensions of Rack Mount (Inch-Based Rack) ..............................................2-6

Figure 2-3. Attachment of Rack Mount Adapter (mm Based)............................................2-7

Figure 2-4. Attachment of Rack Mount Adapter (Inch-Based)...........................................2-7

Figure 2-5. Removal of Feet..............................................................................................2-8

Figure 3-1. Front Panel......................................................................................................3-2

Figure 3-2. Rear Panel ......................................................................................................3-3

Figure 3-3. Oscillator’s Output Terminal ............................................................................3-7

Figure 3-4. Analyzer’s Input Terminals ..............................................................................3-8

Figure 3-5. Dielectric Insulation Voltage of I/O Terminals .................................................3-9

Figure 3-6. Connections with System Under Test ...........................................................3-10

Figure 4-1. Connections for Servo System Measurement.................................................4-3

Figure 4-2. Examples of Expanded Measurement Voltage Range....................................4-5

Figure 5-1. DIP Switches on Rear Panel...........................................................................5-4

Figure 5-2. Command Tree..............................................................................................5-11

Figure 5-3. Status System...............................................................................................5-29

Figure 5-4. Structure of Standard Event Status ..............................................................5-31

Figure 5-5. Structure of Operation Status .......................................................................5-33

Figure 5-6. Structure of Overload Status.........................................................................5-35

Figure 8-1. External Dimensions Diagram.........................................................................8-8

Figures and Tables

FRA5014

viii

Table 2-1. Pakage Contents ..............................................................................................2-2

Table 3-1. Settings and Initial Values ................................................................................3-6

Table 5-1. FRA5014 Subsystem Command List................................................................5-7

Table 5-2. Common Command List ...................................................................................5-9

Table 5-3. Status Byte Register Definitions.....................................................................5-30

Table 5-4. Contents of Standard Event Status Register..................................................5-31

Table 5-5. Contents of Operation Condition Register......................................................5-34

Table 5-6. Contents of Overload Event Register .............................................................5-35

FRA5014

1-1

1. OVERVIEW

1.1 Features ·······························································1-2

1.2 Applications···························································1-2

1.3 List of Functions ·····················································1-3

1.4 Operation Principles ················································1-5

1.1 Features

FRA5014

1-2

1.1 Features

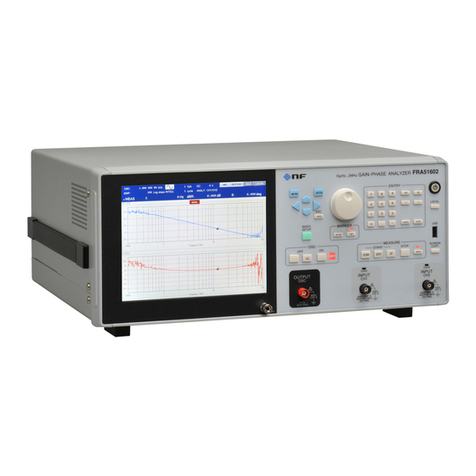

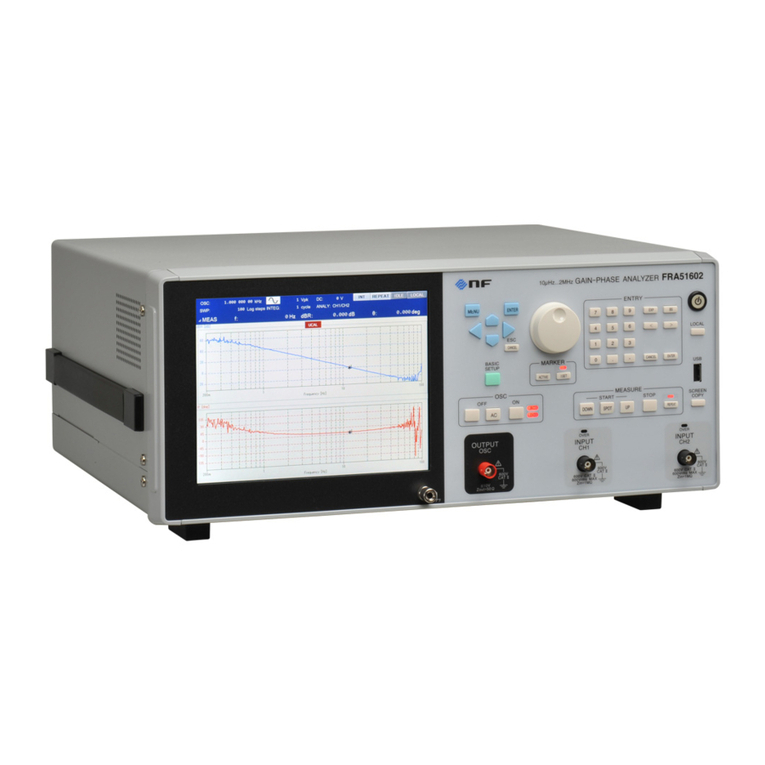

The FRA5014 Servo Analyzer is equipment to evaluate servo system stability and responsivity

through loop characteristics (loop gain and phase vs. frequency) measurement by inputting a sine wave

test signal to the servo system under test.

In addition to servo system evaluation, the FRA5014 is capable of impedance measurement and

frequency characteristic measurement for amplifiers and filters.

The analyzer block consists of 4 channels. Measurements are performed in the four channels

simultaneously, and then 3 combinations of gain and phase using CH1 as the reference (CH2/CH1,

CH3/CH1, CH4/CH1) are analyzed and the results are output. During loop characteristic measurement,

frequency characteristics for each block constituting the loop can also be measured. Furthermore, it

saves measurement time by measuring multiple DUTs simultaneously.

The FRA5014 is a built-in type and dedicated for remote-control via a controller such as a PC.

•Oscillation frequency of 0.1 mHz to 100 kHz

Covers an optimal range for mechanical servo analysis and electrochemical impedance

measurement

•Simultaneous 4-channel measurement

4 channels in the analyzer block simultaneously intake signals. Measurement at low

frequencies can thus be performed faster than devices that switch and analyze input channels

one at a time.

•Insulated I/O

Analysis input of each channel and oscillation output are individually isolated from the case.

This makes signal input to the system under test during servo analysis easy.

•Slim type

Slim shape with a height of 88 mm (2U), suitable for building into a system rack

•Data display software

The standard provided software allows easy data loading into a PC, saving in the CSV format,

and various graph displays.

Measurement setting, control, and data reading are performed by using a PC

1.2 Applications

•Servo system Image stabilization servos in cameras, measurement of servo characteristics

of CD/DVD players, etc.

•Electronic circuits Frequency response measurement in filters, amplifiers, etc.

•Acoustics Frequency response measurement in speakers, microphones, etc.

•Vibration analysis Measurement of resonance characteristics

•Electrochemicals Metallic corrosion research and battery performance measurements

(electrochemical impedance measurement)

1.3 List of Functions

FRA5014

1-3

1.3 List of Functions

A tree diagram of functions is shown below.

Oscillator AC/DC ON

AC/DC OFF

AC OFF

Frequency

AC amplitude

DC bias

rms/peak switch

Sweep UP

measurement DOWN

STOP

Frequency axis

Upper limit frequency

Lower limit frequency

Frequency points

Spot CH2/CH1 Upper limit of acceptable gain range

measurement CH2/CH1 Lower limit of acceptable gain range

CH3/CH1 Upper limit of acceptable gain range

CH3/CH1 Lower limit of acceptable gain range

CH4/CH1 Upper limit of acceptable gain range

CH4/CH1 Lower limit of acceptable gain range

CH2/CH1 Upper limit of acceptable phase range

CH2/CH1 Lower limit of acceptable phase range

CH3/CH1 Upper limit of acceptable phase range

CH3/CH1 Lower limit of acceptable phase range

CH4/CH1 Upper limit of acceptable phase range

CH4/CH1 Lower limit of acceptable phase range

Measurement Integration time

settings Integration cycle

Delay time

Excessive CH1 detection level

input CH2 detection level

CH3 detection level

CH4 detection level

Action when detected ERROR lamp ON

BEEP

STOP

OSC OFF

1.3 List of Functions

FRA5014

1-4

Stored Store settings

settings Read settings

System Execute self calibration

Initialize all settings

Error reset

Interface Select interface GPIB GPIB address

USB Serial number

RS-232 Parity

Stop bits

Baud rate

1.4 Operation Principles

FRA5014

1-5

1.4 Operation Principles

The FRA5014 uses a built-in oscillator to provide a sine wave test signal V0to the system under test,

then measures the following in the vector ratios V2/ V1, V3/ V1, V4/ V1 (i.e., frequencies) of the

response signals V1, V2, V3, and V4

Gain G = | V2/ V1|, | V3/ V1|, | V4/ V1|

Phase differential P = V2−V1, V3−V1, V4−V1

A block diagram of the FRA5014’s operations is shown below.

Figure 1-1. Block Diagram

•Main Processor

The main processor controls the oscillator or analyzer based on the user’s actions, calculates the

ratios of signal vectors obtained by the analyzer, and outputs the data. Employing a quartz

resonator as its reference clock, the main processor uses the direct digital frequency synthesis

method to generate digital sine wave signals (Sin, Cos) with precise frequencies for use by the

oscillator or analyzer.

V4

GPIB

USB

Isolator

Isolator

RS-232

V0

V1

V4

Main Processor

Panel

DIP SW & Lamp

Isolator

System Under Test

Signal vector

Analyzer CH4

Sub Processor

Signal

Conditioner

A/D

Sin

Cos

Analyzer CH1

Sub Processor

Signal

Conditioner

A/D

Sin

Cos

Oscillator

DC Bias

D/A

Amplitude

V0

V1

V3

V2

1.4 Operation Principles

FRA5014

1-6

•Oscillator

The FRA5014’s oscillator uses a D/A (digital to analog) converter and filter to convert digital

sine wave signals into analog signals. Lastly, DC bias is added prior to output.

•Analyzer

In the analyzer, response signals from the system under test are modified in size, etc., as needed

by a signal conditioner, then are converted to digital signals by an A/D (analog to digital)

converter. The sub processor performs multiplication and integration operations using the

response signal and orthogonal reference signals (Sin, Cos) to obtain two orthogonal signal

components, which is to say signal vectors. This process attenuates frequency components that

do not match the signal frequency, thereby enabling precise measurement even when a lot of noise

is present.

FRA5014

2-1

2. PREPARATIONS BEFORE USE

2.1 Checking Before Use···············································2-2

2.2 Installation·····························································2-3

2.2.1 General precautions for installation ······················2-3

2.2.2 Installation conditions ········································2-3

2.2.3 Rack mount·····················································2-4

2.3 Grounding and Power Supply Connections ··················2-9

2.4 Simple Operation Checks ·······································2-10

2.5 Calibration··························································· 2-11

2.1 Checking Before Use

FRA5014

2-2

2.1 Checking Before Use

◼Safety check

Before using the FRA5014, carefully read “Safely Precautions” at the front of this manual to

ensure safety.

Before connecting the mains supply cord, read “2.3 Grounding and Power Supply Connections”

and perform all of the safety checks.

( Cautions when unpacking

First, make sure that no damage has occurred during shipment.

Before installing the equipment, check that all of the items listed in “ REF _Ref171138824 \h

\* MERGEFORMAT Table 2-1 REF _Ref182282031 \h \* MERGEFORMAT

Pakage Contents” are included.

Table 2-1. Pakage Contents

Using the data display software in the supplied CD-ROM, data can be loaded from the FRA5014 to

a personal computer, where it can be stored in CSV format, displayed in various types of graphs, and

the main parameters of the data can be easily modified.

This manual does not include instructions on using all of the contents of the CD-ROM. For details

of these contents, see the instruction manual that is included in the CD-ROM. To view the

CD-ROM contents, Adobe Corporation’s Acrobat Reader Ver. 5 is required, and must be installed

separately (this program was called “Adobe Reader” when this manual was created).

This product contains high-voltage parts. Never remove the cover.

All internal inspections of this product are to be performed only by service technicians who

are familiar with risk prevention and who are qualified by NF Corporation.

FRA5014 main unit ··························································· 1

Mains supply cord (with 3 pin plug, 2 m)································· 1

Instruction Manual ····························································· 1

CD-ROM·········································································· 1

Contents •Data display software

•LabVIEW driver

•Sample programs

•FRA5014 Instruction Manual (pdf format)

!

WARNING

Table of contents

Other NF Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

Sper scientific

Sper scientific 300005 instruction manual

Hanna Instruments

Hanna Instruments HI97727 instruction manual

Stahl

Stahl Series 8146/5075 operating instructions

Rx Monitoring Services

Rx Monitoring Services CX Plus installation manual

Inepro

Inepro DMMetering PRO1250D user manual

Vega

Vega vegaflex 83 operating instructions