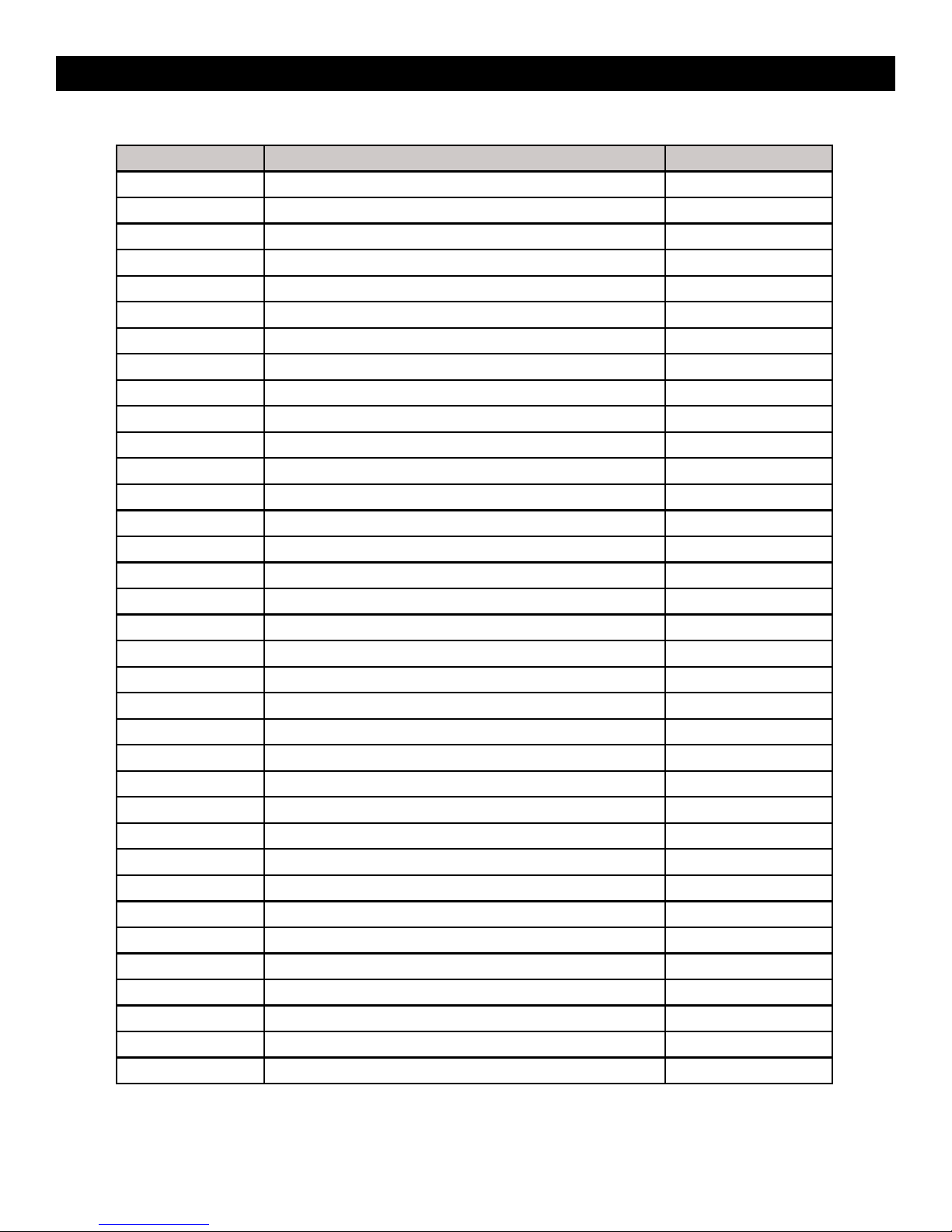

3

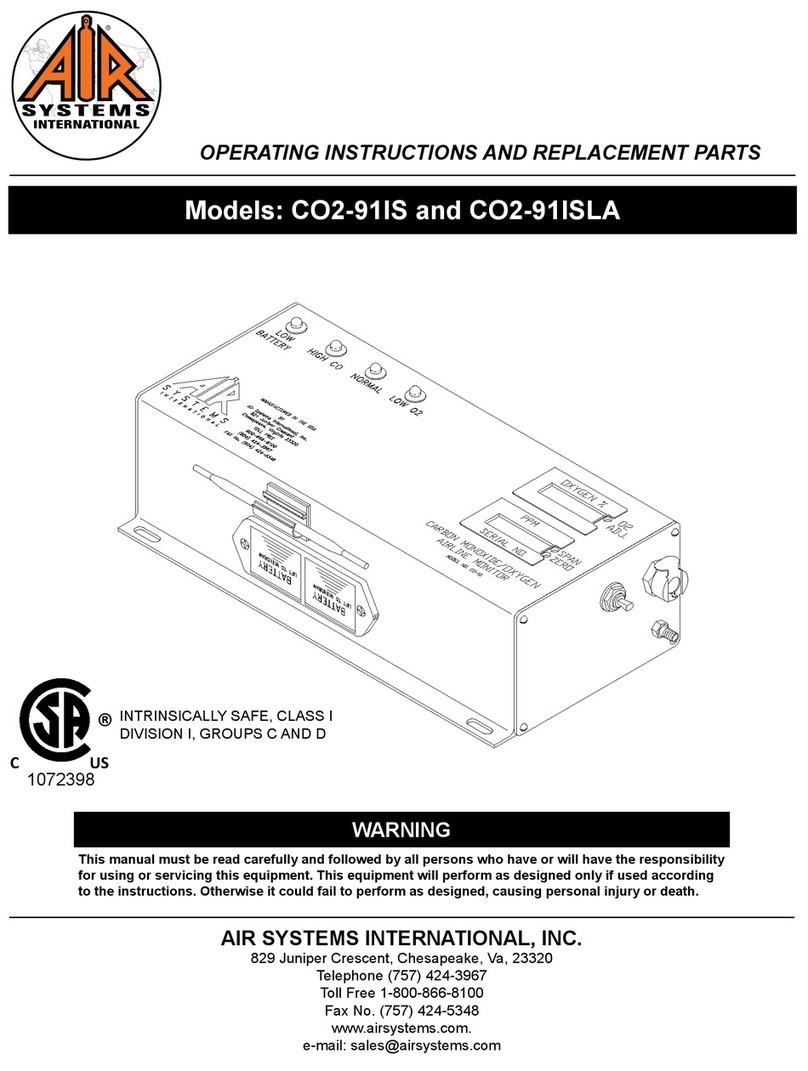

Size 2.75”H X 6.57”L X 5.1”W

Weight 2.8 lBS. (1.27kg.)

Case Extruded Aluminum - anodized black

Voltage 9 VDC

Operating

Temperature

4° to 113° Fahrenheit

(-15.5° to 45° Celcius)

Humidity

Range 10% to 90% relative humidity

Flow

Requirement 50 - 100 cc/min

Display 3 digit LCD

CO concentration

Test Circuit Manually activated

Sensor Type Sealed electrochemical sensor for

Carbon Monoxide

Accuracy +/-1% full scale

Response 90% in 10-15 seconds

Detectable

Range 0-200 ppm CO

Calibration Manual CO zero and span adjustments

Alarm Setting 10 ppm CO (5 ppm - Canadian)

Warning

Signals

Normal Operation - Green Light

High CO - Red Light

High CO - Audible Alarm

Low Battery - Amber Light

Warranty 2 years from original date of purchase

Filter Housing/Bowls: Periodic cleaning of the polycarbonate bowls may become necessary. Remove the auto drains and

clean the bowls with a mild soapy solution. The auto drains may also be cleaned with a mild soapy solution at this time.

Dry and reinstall into the fi lter housing.

Filter Change: The fi ltration system consists of fi lter change indicators which will gradually change from green to orange

when fi lter life is spent.

Note: Air must be owing through the fi lters before the fi lter change indicators will function.

Calibration

: Monitor calibration should be done monthly or whenever the reading may be questionable. A calibration date

sticker should be affi xed for future reference. To obtain an accurate calibration, we recommend the use of Air Systems’

calibration kits.

Part Number:

BBK-10 Canadian calibration kit for CO monitor; 10ppm CO, zero air, regulator and case - 17 liter size.

BBK-20 Calibration kit for CO monitor; 20ppm CO, zero air, regulator and case - 17 liter size.

BBK-20103 Calibration kit for CO monitor; 20ppm CO, zero air, regulator and case - 103 liter size.

DECAL085CD Calibration decal card, contains 14 calibration decals.

To assure sensor accuracy, calibration of monitor is required. If you cannot obtain an accurate calibration, sensor replace-

ment may be necessary. Consult Repair Service Department before ordering.

Part Number:

CO-91NS Replacement CO sensor

CAUTION: Always depressurize the system before performing service.

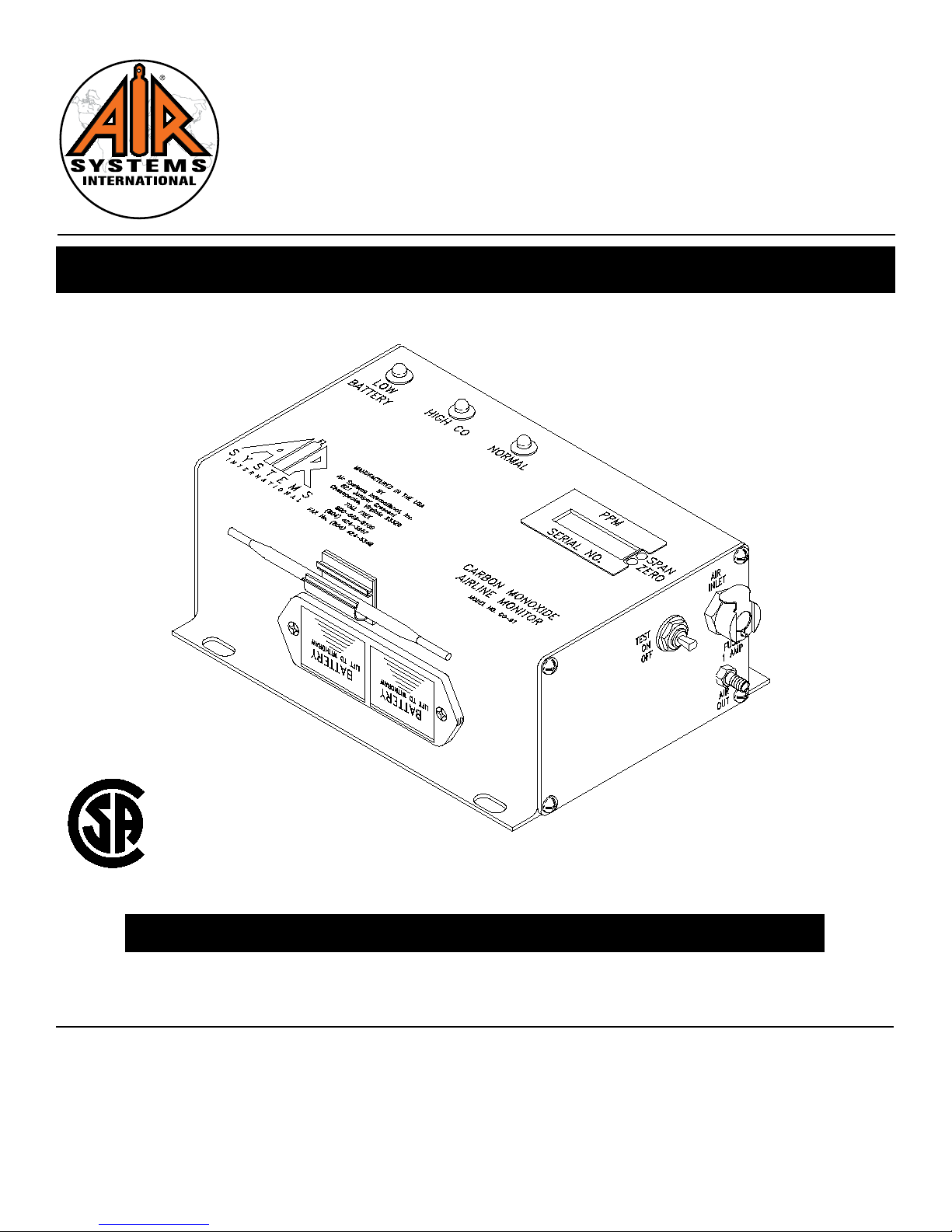

The monitor will analyze the air sample and display the CO concentration in parts per million (ppm). The system’s green

“NORMAL” operation light will illuminate and the red “HIGH CO” light will icker approximately every second when the CO

level is below 10ppm (5ppm Canadian). If the CO concentration level exceeds the alarm set point, the green “NORMAL”

light will turn off, the red “HIGH CO” light will illuminate, the audible alarm will sound, and the remote alarm connections

will energize. Once the CO concentration levels drop below the alarm set point, all alarm indicators will deactivate and the

unit will return to “NORMAL” operation.

Overview

Monitor Specications

Maintenance Items