3

IMAT PT- E GB

1) GENERAL

This instruction manual contains important information regard-

ing the installation, operation, maintenance and storage for

POWER TECHNOLOGY rack and pinion pneumatic actuators.

Please read these instructions carefully and keep them for fu-

ture reference. It is important that the use and maintenance of

the actuator is made only by properly trained personnel.

2) WARNING

• Do not operate the actuator using inflammable, oxidiz-

ing, corrosive, explosive or unstable gases or liquids

(use only not dangerous fluids - group 2 according

to 2014/68/EU directive). Moreover, for actuators

installed in potentially explosive zones, make sure that

the internal parts of the actuator do not come into

contact with the external atmosphere.

•Referring to the Machinery Directive 2006/42/EC, the

actuators can be classified as “PARTLY COMPLETED

MACHINERY” (see the DECLARATION OF INCORPO-

RATION). Therefore the actuator can not put into service

until the machinery and/or the system, where the actua-

tor is incorporated, will be declared in compliance with

the requirements of the Directive 2006/42/EC.

• POWER TECHNOLOGY actuators are designed, pro-

duced and classified according to the ATEX

Directive 2014/34/EU (see actuator label and safety

instructions). The use of the actuators in potential

explosive atmosphere zones has to comply with the

ATEX classification indi-cated on the actuator label

and according to the ATEX safety instructions.

• The use, the installation and the maintenance of the POW-

ER TECHNOLOGY actuators must be made by adequately

trained personnel. For the use, installation and mainte-

nance of POWER TECHNOLOGY actuators it is recom-

mended to comply to the safety notice and to use proper

equipment to protect health and prevent accidents.

• It is important that the actuator is used only within the

working limits indicated in the technical specifications.

•

Do not operate the actuator over temperature limits: this

could damage internal and external components (disas-

sembly of spring return actuator may become dangerous).

• Do not operate the actuator over pressure limits: this

could damage internal parts as well as cause damage

to the housing and end-caps.

• Do not use the actuator in corrosive environments with

incorrect protection: this could damage the internal and

external parts.

• Do not disassemble individual spring cartridges, this

may result in personal injury. If maintenance to springs

is necessary, send them to AIR TORQUE.

• Close and disconnect all air supply lines and make sure

that air connections are vented during maintenance and

installation on valve.

• Do not disassemble the actuator or remove end caps

while the actuator is pressurized.

• The POWER TECHNOLOGY actuators are designed to

be used only on valves.

• Before installing the actuator onto the valve make sure

that the rotation direction and the position indicator are

in the correct position.

• If the actuator is incorporated in a system or used within

safety devices or circuits, the customer shall ensure that

the national and local safety laws and regulations are ob-

served.

• In case the actuator is installed on a valve with a

gearbox for emergency manual operation, make sure

that the stroke of the gearbox does not exceed the

stroke allowed by the actuator. Caution: make sure

that the gearbox stroke, both in closed and in opened

position, is properly adjusted.

If you exceed the stroke allowed by the actuator with

the manual operation of the gearbox, you can cause

severe damage to the adjustment screws, to the

pistons and to the actuator itself.

3) WORKING CONDITIONS AND TECHNICAL DATA

• Operating media:

Dry or lubricated air or inert gases, provided that they are

compatible with the actuator internal parts and lubricant.

The operating media must have a dew point equal to

-20°C (-4°F) or at least 10°C below the ambient tempera-

ture. The maximum particle size contained into the operat-

ing media must not exceed 30 μm.

• Supply pressure:

The maximum supply pressure is 8 bar (116 Psi).

For double acting and spring return actuators the working

pressure is from 2.5 bar (36 Psi) to 8 bar (116 Psi).

• Operating Temperature:

⇒“Standard” actuators from -40°C (-40°F) to +80°C

(+176°F)

⇒Actuators for high temperature “HT” from -15°C (+5°F)

to +150°C (+300°F)

⇒Actuators for extreme low temperature “LLT” from

-55°C (-67°F) to + 80°C (+176°F)

Caution: for low and high temperature service, special

grease and special components are required. Please con-

tact AIR TORQUE. Working at high or low temperature

can affect the life and the output torque of the actuator.

• Operating Time (see Technical Data Sheet):

Caution: the operating time depends on several factors

such as supply pressure, supply system capacity (pipe

diameter, flow capacity of pneumatic accessories), valve

type, valve torque and figures, applied safety factor, cycle

frequency, temperature, etc.

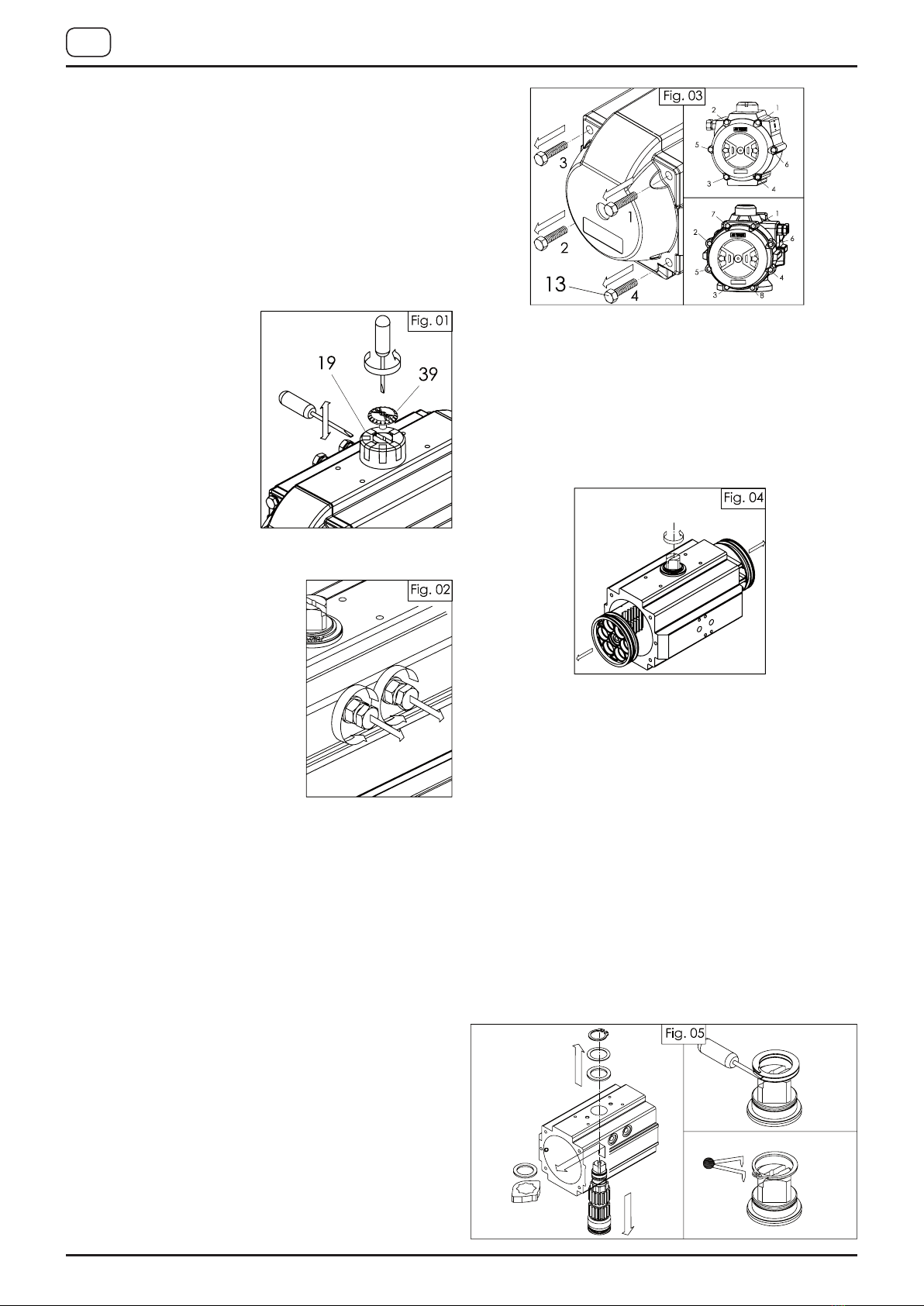

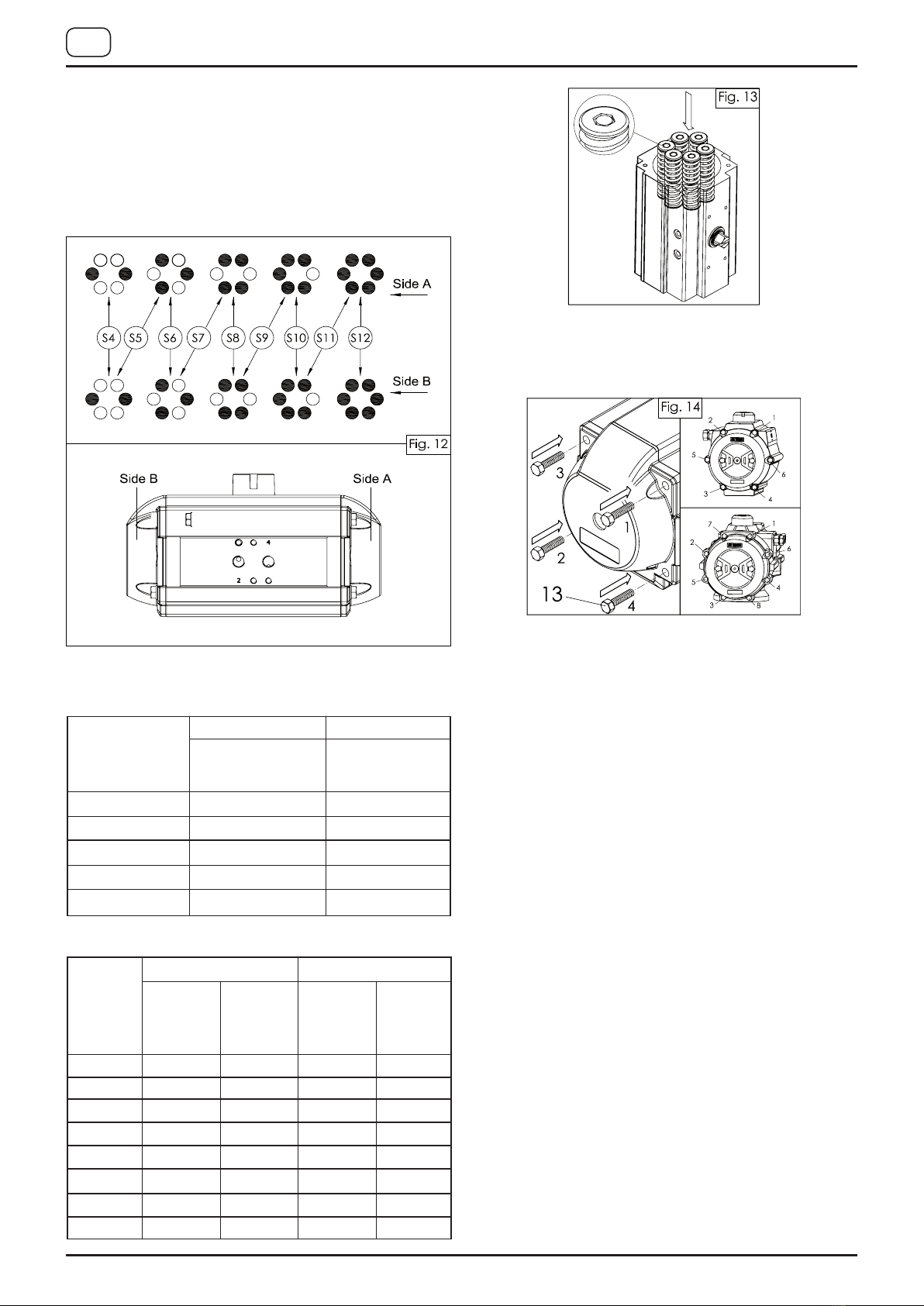

•Rotation and stroke adjustment (see technical data sheet):

For standard actuators (90° rotation), 120° actuators (120°

rotation), 135° actuators (135° rotation) and 180° actua-

tors (180° rotation).

Stroke adjustment at 0°(closed pistons): +5°/- 5°. Stroke

adjustment at 90°, 120°, 135° and 180°(open pistons):

+5°/-5°. For actuator PT045 the stroke adjustment at 90°

(open pistons) is available only on request.

• Lubrication:

The actuators are factory lubricated for the

life of the actuator in normal working condi-

tions. The standard lubricant type GSTD is suit-

able for use from -40°C (-40°F) to +80°C (+176°F).

For extreme low temperature (LLT) and high temperature

(HT) service, special grease is required: please contact

Air Torque. Actuators with protection level “L” need spe-

cial grease (type GA-LT).

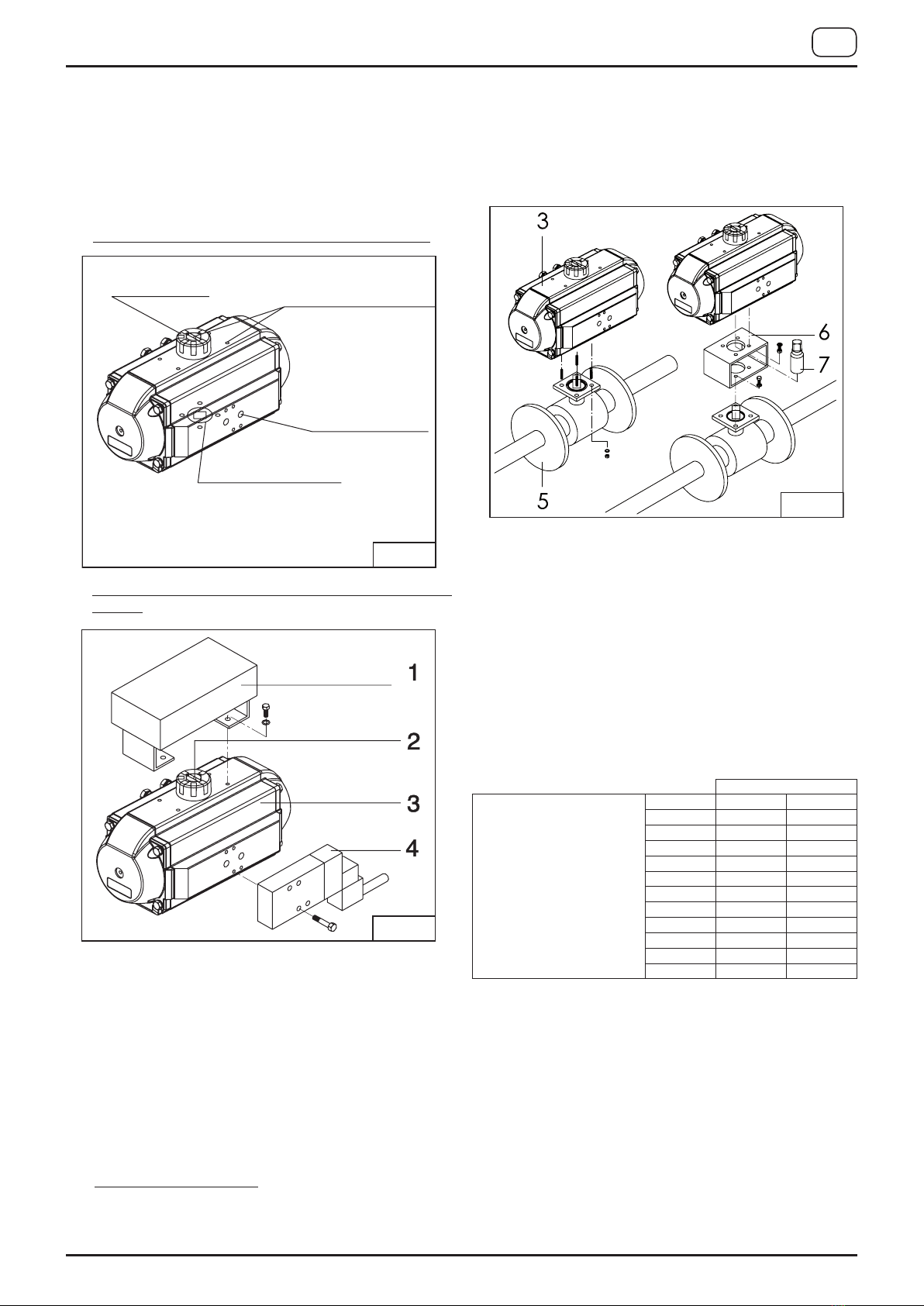

• Construction:

Rack and pinion actuator design suitable for both indoor

or outdoor installations.

• Protection and Corrosion resistance:

All the actuators are supplied with corrosion protection for

normal environments. For corrosion resistance of the dif-

ferent types of protection see technical data sheet.