5

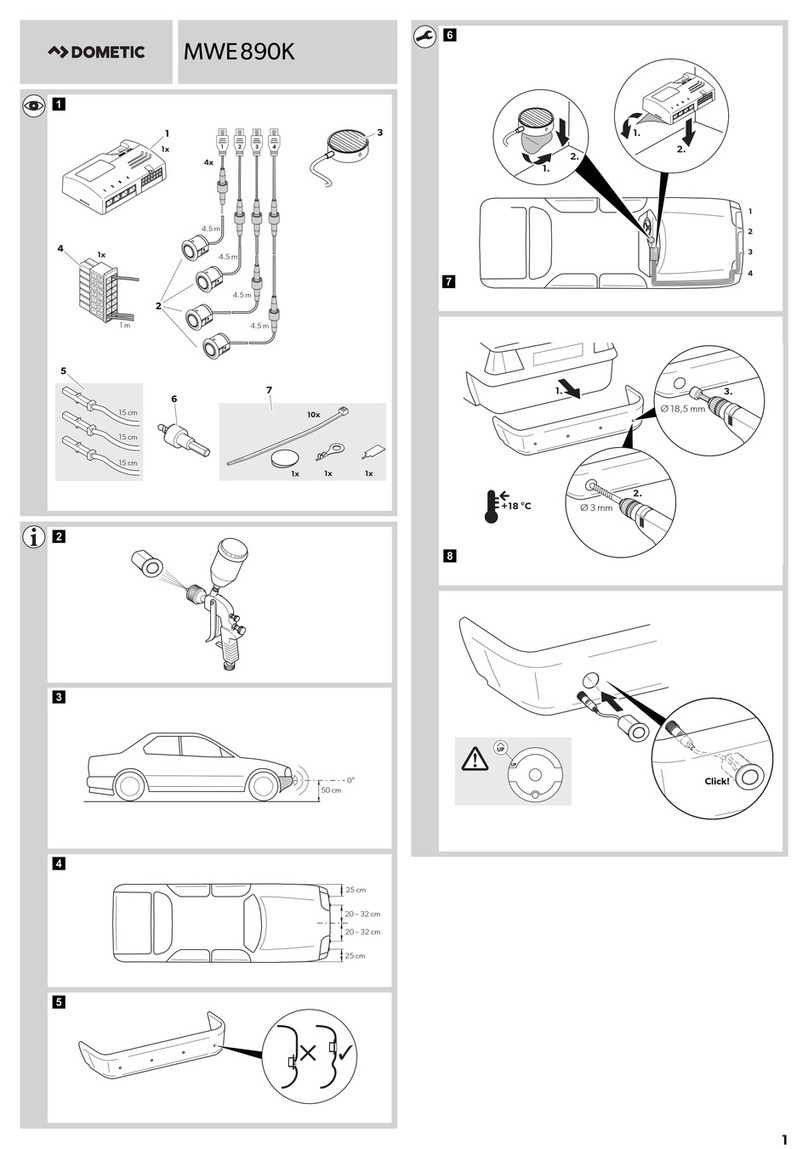

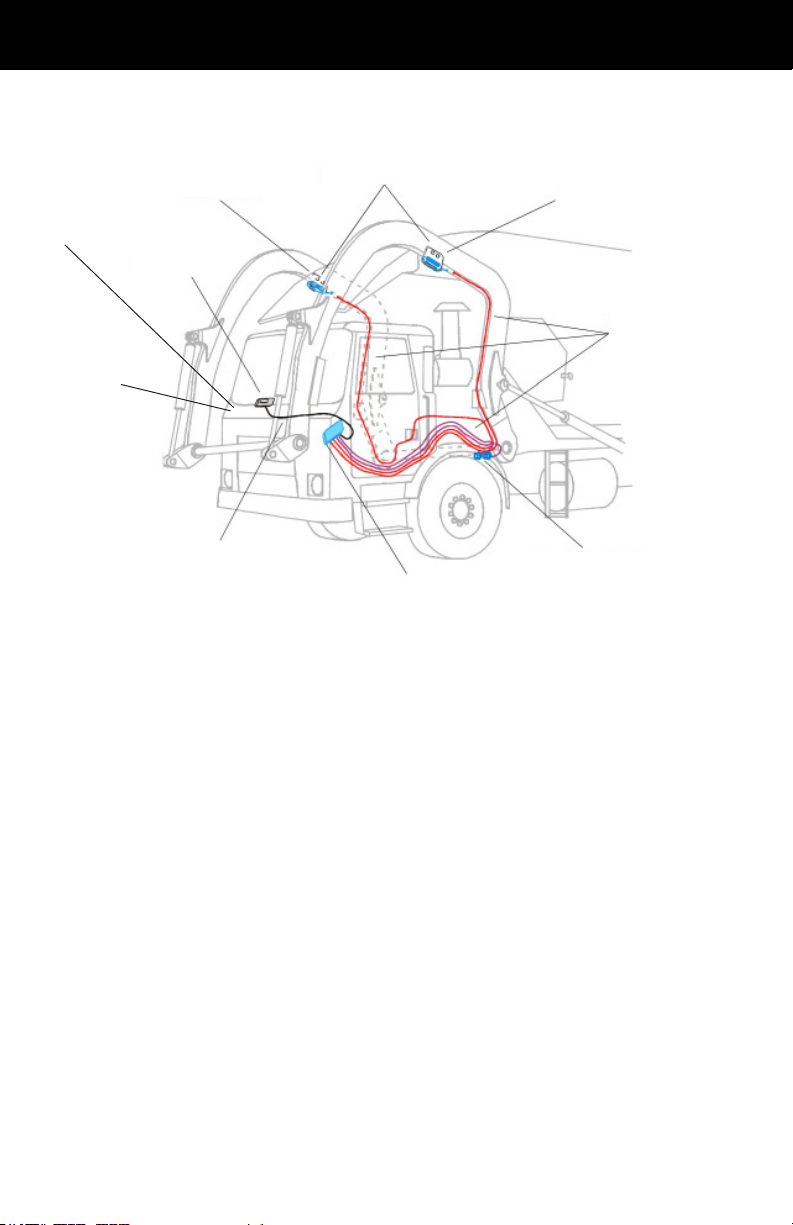

Installing the Deection Sensors

Thedeectionsensorsmeasuretheexintheliftarmsasthetruck

raisesandlowersbins.BinMaxxusestwosensors,oneforeach

arm.Eachsensorismountedtoasetofarmbracketsoneachside

ofthetruck.

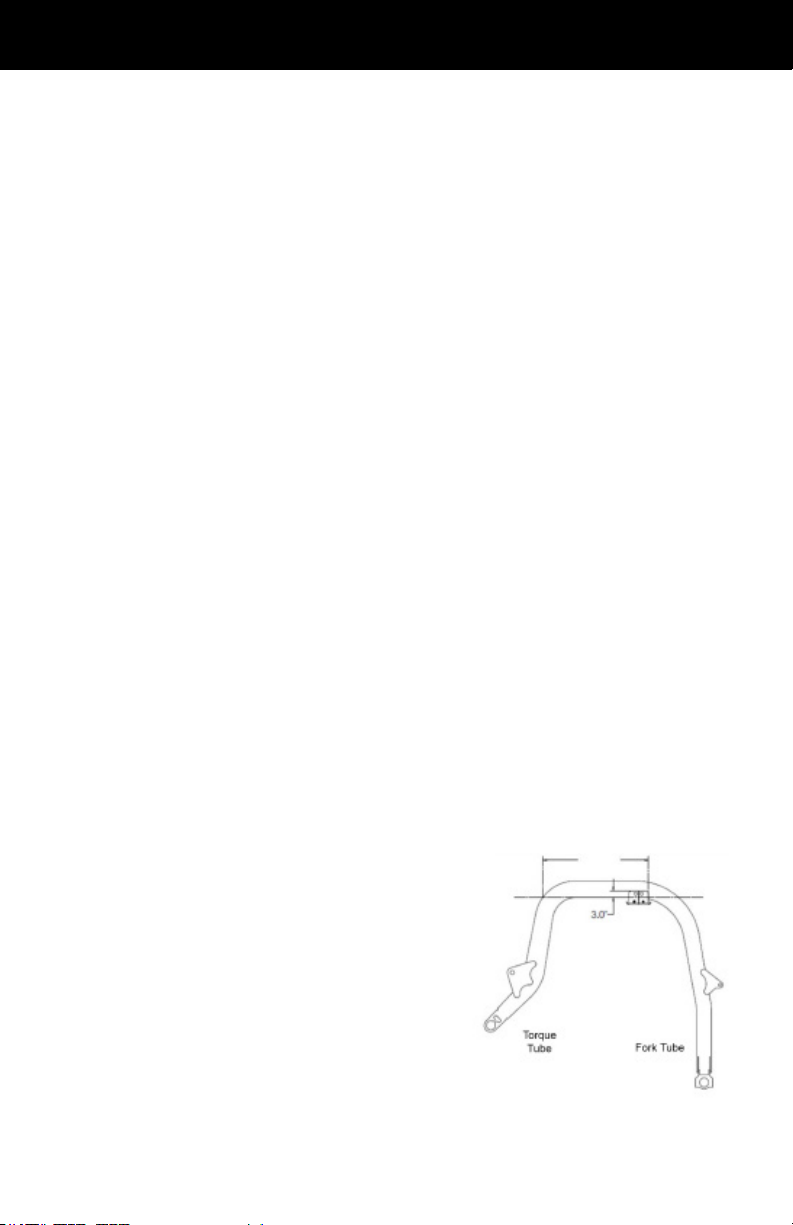

Choosing a Location for the Brackets

• Thebracketsshouldbeasclosetotheupperforward

curve(closesttotheforksofthetruck)whileremaining

level(i.e.notinthecurve).

• Thebracketsshouldnotbeplacedoveranyhydraulic

clamps,couplersorotherhardware.(OEMweldsmay

needtobegrounddowninordertoplacetheBinMaxx

armbracketinthemostoptimumlocation.)

• Thebracketsand/orarmsensorscannotbeincontact

withanyothertruckcomponent,suchasanarmmounted

hydrauliclineoranarmcable.

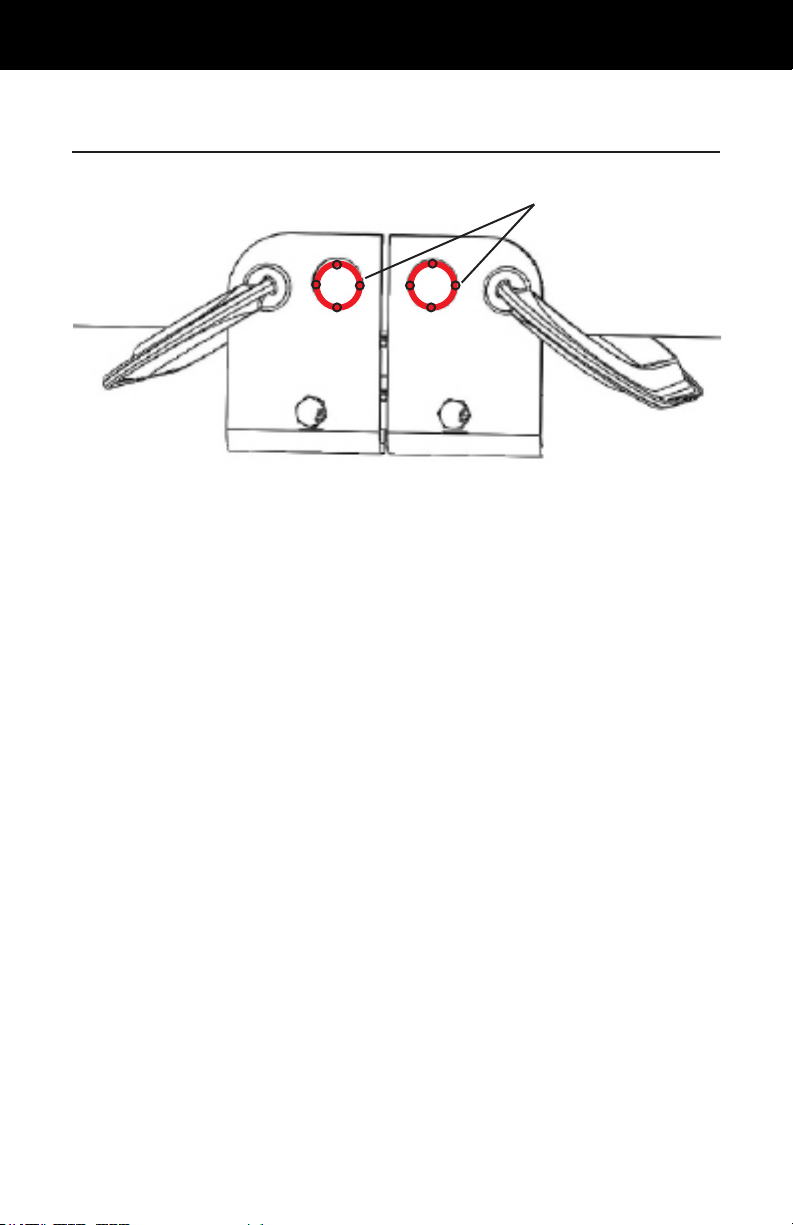

• Thebracketsneedtobeplacedinthesamepositionon

botharms.Verifypositioningonbotharmspriortowelding

thebracketsoneitherside.Ensurethattheposition

chosen does not have any interference on either side.

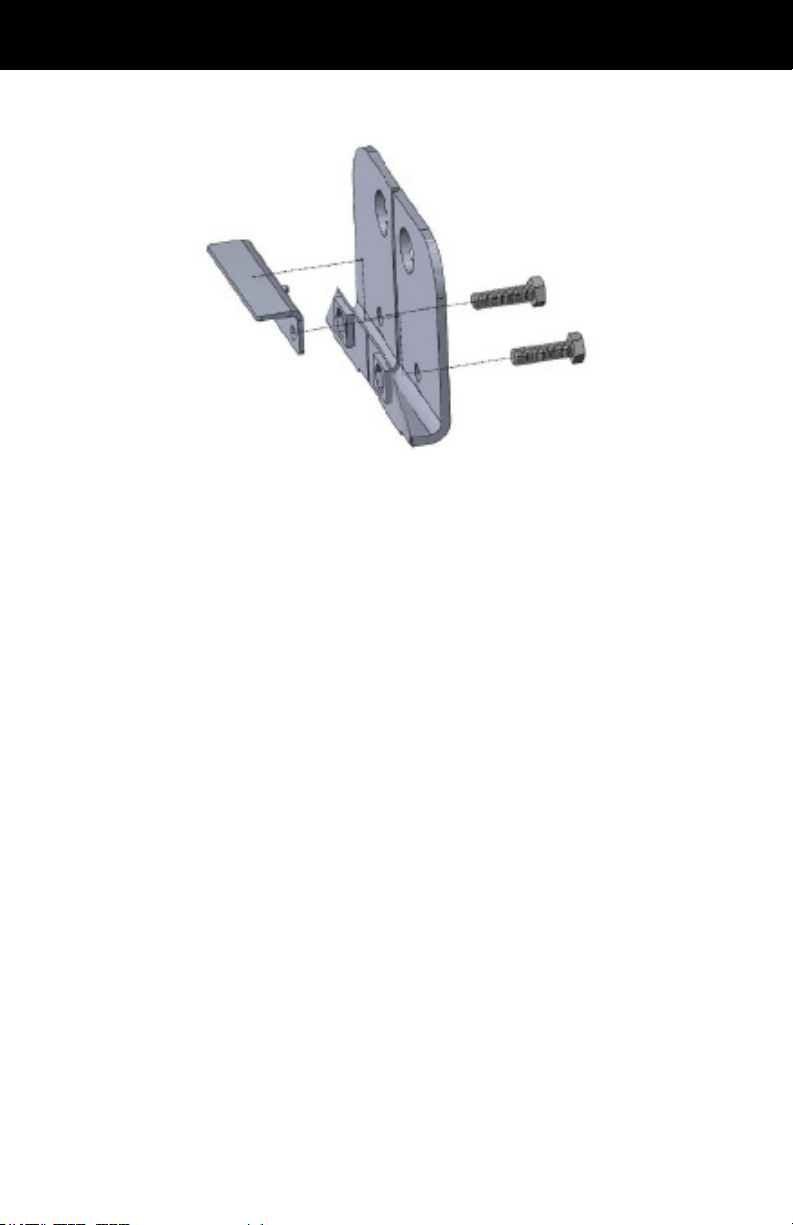

• Thebracketsshouldbeplacedsothatthereisenough

spacetoinstallorremovethedeectionsensors.Leave

thealignmenttool(Jig)inthebracketduringweldingto

ensurethatthereisenoughspace.

• If an arm weld seam or plug is located in the optimum

position for the arm

brackets, grind the arm weld

seam down until it is smooth

and ush with the arm and

then position and weld the

arm sensor brackets to that

location. Positioning of

the scale’s brackets must

supersede the existence

of any OEM welds when a

conict occurs.

Placing the Bracket on the Lift Arm