2

Table of

Contents

TABLE OF CONTENTS.................................................................2

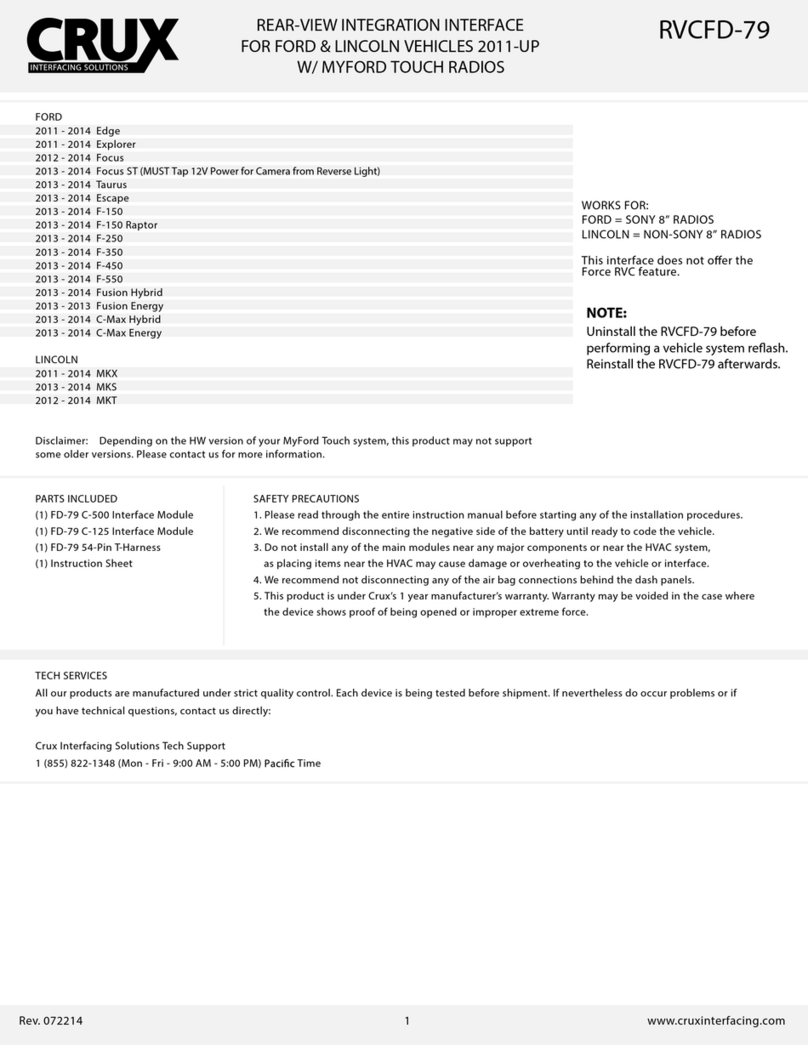

ABOUT LOADMAXX FOR F-750...................................................4

ABOUT INSTALLATION................................................................5

Overview.............................................................................5

Installation Components...................................................... 5

TOOLS REQUIRED .......................................................................6

Optional Tools.................................................................. 6

INSTALLING THE STEER AXLE SENSOR BRACKET..................7

Preparing the Steer Axle Sensor Brackets........................... 7

Welding the Bracket ............................................................ 9

Adding a Protective Spray Paint Coating........................... 10

INSTALLING THE DRIVE AXLE SENSOR ..................................11

Assembling the Bracket to the Jig...................................... 11

Surface Preparation........................................................... 12

Welding the Bracket .......................................................... 13

Installing the Deflection Sensor ......................................... 14

INSTALLING THE COMLINK AND DISPLAY ..............................16

Preparing the Cab Display for Installation.......................... 16

Installing the Cab Display.................................................. 16

Mounting the ComLink....................................................... 17

Connecting Cables............................................................ 18

Table 2: Wiring Harness Hookup.................................... 18

Routing Cables.................................................................. 19

Securing Cables and Reassembling the Dash................... 19

INSTALLING AND ADJUSTING THE STEER AXLE SENSOR ....20