©AirBorne WindSports Pty. Ltd.

XT 582 Maintenance Manual

Issue 1.0

September 21st 2005 Page 9

LIST OF TABLES

Table 1 XT 582 Data Package............................................................................................................... 2

Table 2 Amendment Record Sheet........................................................................................................ 3

Table 3 Log Of All Effective Pages, Issue 1........................................................................................... 4

Table 4 Imperial / Metric Conversions.................................................................................................... 7

Table 5 Initial Assembly Procedure (GJP144) ..................................................................................... 11

Table 6 Airframe Limitations ................................................................................................................ 15

Table 7 Time Limits of Components .................................................................................................... 16

Table 8 Propeller and Gearbox Maintenance Schedule ....................................................................... 18

Table 9 Engine Maintenance Schedule ............................................................................................... 20

Table 10 Trike Base and Landing Gear Maintenance Schedule .......................................................... 21

Table 12 Torque Table ........................................................................................................................ 43

Table 13 Excerpt from GJP 141, Complete List of Tie Wire locations .................................................. 44

Table 14 Fuel Tank Schematic ............................................................................................................ 51

Table 15 SkyDAT Monitored Operations.............................................................................................. 91

LIST OF FIGURES

Figure 1 Main structural members ....................................................................................................... 12

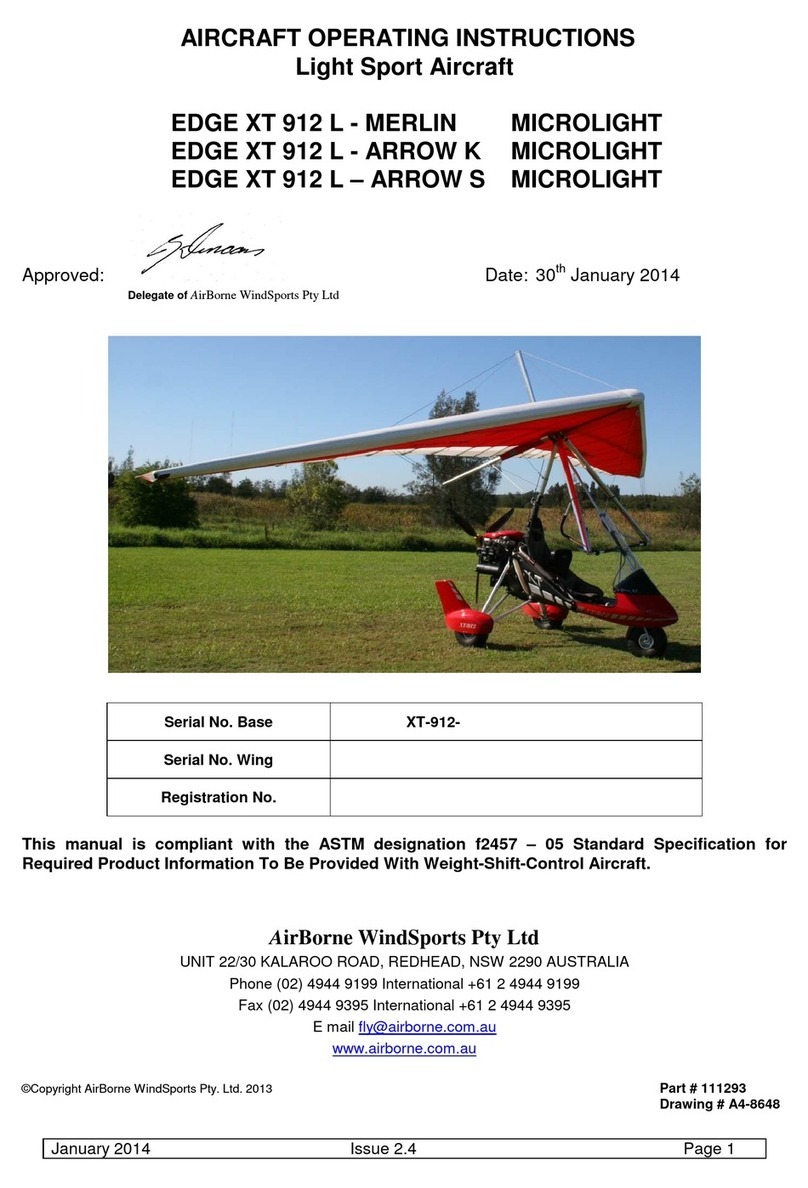

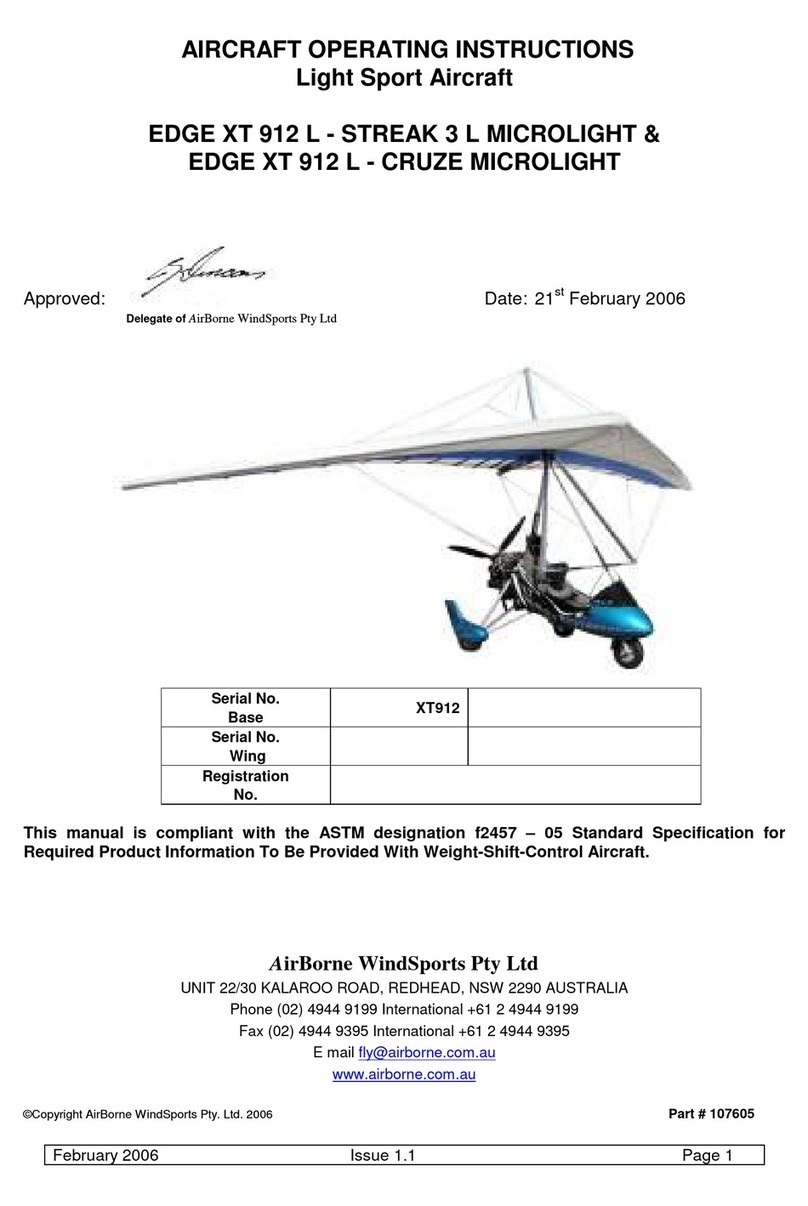

Figure 2 Cockpit (XT 912 shown in photo) ........................................................................................... 12

Figure 3 Under-seat bags .................................................................................................................... 13

Figure 4 Mast Block Area (XT 912 shown in photo) ............................................................................. 13

Figure 5 Steering and foot levers......................................................................................................... 14

Figure 6 Power plant............................................................................................................................ 14

Figure 7 Front Mast to Mast Brace Check............................................................................................ 22

Figure 8 Major Dimensions (XT912 Shown) ........................................................................................ 24

Figure 9 Tie Down Hook Location........................................................................................................ 28

Figure 10 Front wheel with tie downs................................................................................................... 28

Figure 11 Tie on Rear Wheel............................................................................................................... 29

Figure 12 Trike on Trailer .................................................................................................................... 29

Figure 13 Parking of Trike (Upwind Wing Down) ................................................................................. 30

Figure 14 Securing of Base Bar With Bungee...................................................................................... 30

Figure 15 Parking Trike Tail to the Wind.............................................................................................. 31

Figure 16 Fuel Specifications............................................................................................................... 33

Figure 17 Air filter protection during cleaning....................................................................................... 37

Figure 18 Seat Mast Block Sub Assembly ........................................................................................... 40

Figure 19 Outside Nut with spat bracket .............................................................................................. 41

Figure 20 Inside Nut and Inner Spat Bracket ....................................................................................... 41

Figure 21 View of Locking Bolt head.................................................................................................... 41

Figure 22 Tie Wires on Propeller ......................................................................................................... 44

Figure 23 Rear Wheels Special Safetying............................................................................................ 44

Figure 24 Muffler Safety Wire and Springs .......................................................................................... 45

Figure 25 Mast Top Safetying.............................................................................................................. 45

Figure 26 Finger Filter, as installed, as well as the unit prior installation. ............................................. 53

Figure 27 Fuel Line Check Example .................................................................................................... 54

Figure 28 Fuel Flow Sender Device..................................................................................................... 55

Figure 29 Fuel Sender and tools.......................................................................................................... 56

Figure 30 Fuel Tap Bracket Sub Assembly.......................................................................................... 57

Figure 31 SkyDAT Console Photo ....................................................................................................... 58

Figure 32 Features of the Instrumentation ........................................................................................... 58

Figure 33 Rear Shock Dimension Check ............................................................................................. 61

Figure 34 Front Shock Set up .............................................................................................................. 62

Figure 35 Steering Damper Setting, (Dwg # 5610). ............................................................................. 62