800.909.9709

www.AirCycle.com [3]

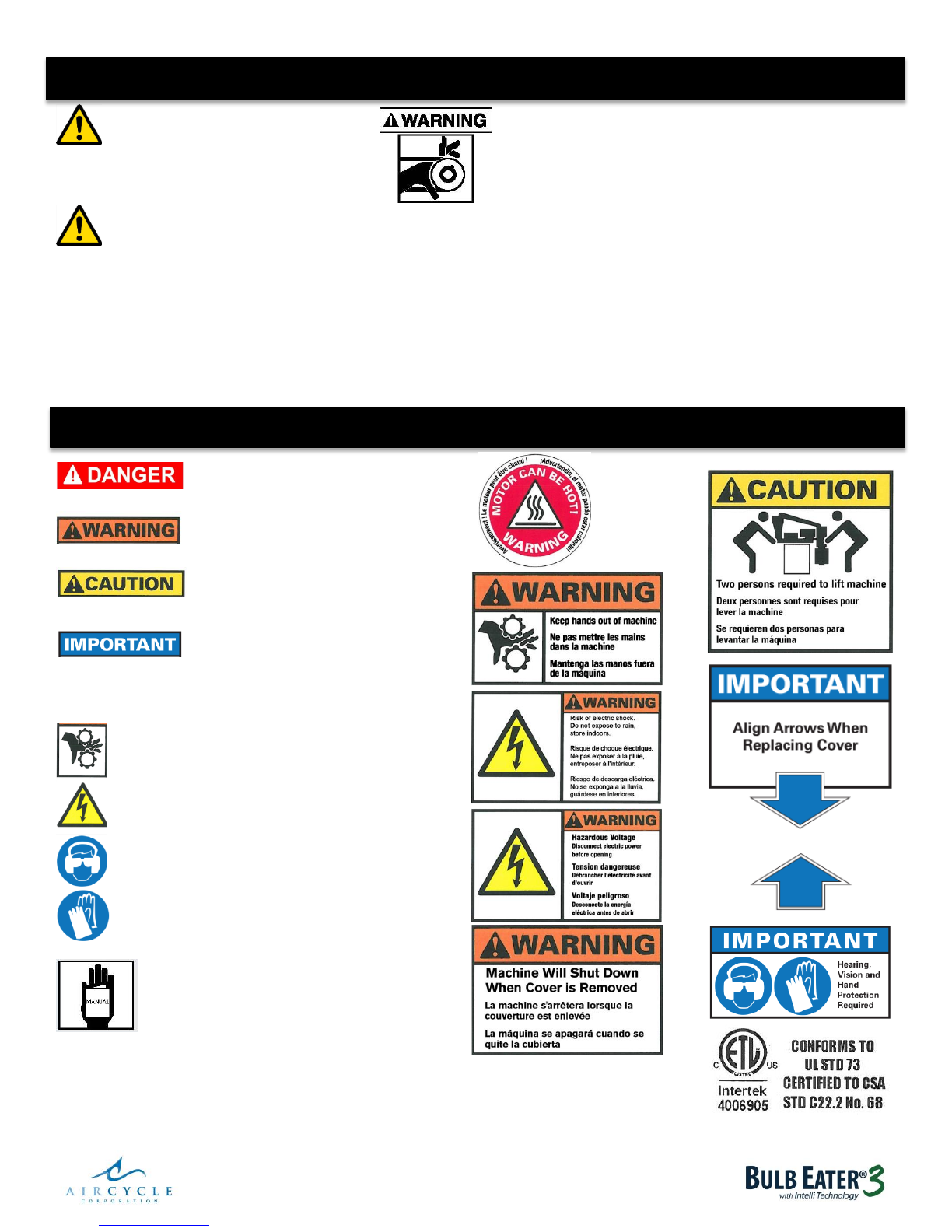

WARNING –DO NOT LEAVE Bulb Eater®3 MACHINE UNATTENDED WHEN IT IS PLUGGED IN

AND/OR OPERATING. UNPLUG UNIT WHEN NOT IN USE.

11. Do not handle plug or machine with wet hands.

12. Close supervision is necessary when a machine is

used near children.

13. Keep hair, loose clothing, fingers and all parts of

body away from openings and moving parts.

14. Do not use without filters in place. May disperse

fine dust particles into the air.

15. Turn off all controls before unplugging.

16. Do not use in areas where combustible liquids such

as gasoline may be present.

17. Do not vacuum toxic, carcinogenic, combustible or

other hazardous materials such as asbestos,

arsenic, barium, beryllium, lead, pesticides or other

health endangering materials. Specially designed

units are available for these purposes.

18. Do not leave the cord lying on the floor when the machine

is not being operated. It can become a tripping hazard.

19. Use special care when emptying heavily loaded drums.

drums.

20. Always wear safety goggles and hearing protection when

operating the machine.

21. STAY ALERT. Watch what you are doing and use

common sense. Do not use the BE3 machine when

you are tired, distracted or under the influence of

drugs, alcohol or medication causing diminished

control.

When using an electrical appliance or machine, basic precautions

should always be followed, including the following: READ ALL

INSTRUCTIONS BEFORE USING THIS APPLIANCE/MACHINE.

WARNING –TO REDUCE THE RISK

OF FIRE, ELECTRIC SHOCK OR INJURY:

1. Do not leave machine unattended when plugged in. Unplug

from outlet when not in use and before servicing. Connect

to a properly grounded outlet only. See Grounding

instructions.

2. Do not put machine in water or other liquid.

3. Do not expose to rain –store indoors.

4. Do not place or store machine where it can fall or be

pulled into a tub or sink.

5. Use only as described in this manual. Use only

manufacturer’s recommended attachments.

6. Do not use with damaged cord or plug. If machine is

not working as it should, has been dropped,

damaged, left outdoors or dropped into water, contact

Air Cycle Corporation for assistance. Replace with specific

part of machine in question.

7. Do Not: pull or carry by cord, use cord as a handle,

close a door on cord or pull cord around sharp edges

or corners. Do not run machine over cord. Keep

cord away from heated surfaces.

8. Do not unplug by pulling on cord. To unplug, grasp

the plug; not the cord.

9. Do not put any object into openings. Do not use with

any openings blocked; keep free of dust, lint, hair and

anything that may reduce air flow.

This machine must be grounded. If it should malfunction or breakdown, grounding

provides a path of least resistance for electric current to reduce the risk of electric

shock. This machine is equipped with a cord having an equipment-grounding conductor

and grounding plug. The plug must be inserted into an appropriate outlet that is

properly installed and grounded in accordance with all local codes and ordinances.

WARNING –IMPROPER

CONNECTION OF THE MACHINE GROUNDING

CONDUCTOR CAN RESULT IN A RISK OF ELECTRIC

SHOCK. CHECK WITH A QUALIFIED ELECTRICIAN

OR SERVICE PERSON IF YOU ARE IN DOUBT AS TO

WHETHER THE OUTLET IS PROPERLY GROUNDED.

DO NOT MODIFY THE PLUG PROVIDED WITH THE

MACHINE –IF IT WILL NOT FIT THE OUTLET, HAVE

A PROPER OUTLET INSTALLED BY A QUALIFIED

ELECTRICIAN.

This machine is for use on a nominal 120-vac or 240-vac power,

and has a plug that looks like the

plug illustrated in the sketch. A

temporary adapter that looks like

the adapter illustrated in the sketch

may be used to connect

this plug to a 2-pole receptacle,

as shown, if a properly grounded

outlet is not available. The

temporary adapter should be

used only until a properly grounded

outlet (sketch) can be installed

by a qualified electrician. The green colored rigid ear, lug or the like extending

from the adapter must be connected to a permanent ground such as a properly

grounded outlet box cover. Whenever the adapter is used, it must be held in

place by a metal screw.

IN CANADA, THE USE OF A TEMPORARY ADAPTER IS NOT PERMITTED BY

THE CANADIAN ELECTRICAL CODE. Make sure that the machine is connected

to an outlet having the same configuration as the plug. No adapter should be

used with this machine.

IMPORTANT SAFETY INSTRUCTIONS