© Airow - we reserve the right to make changes without prior notice

Uno hab PSF Switching Power Supply-Flush Installation and Operating Instructions

INSTALLATION AND OPERATING INSTRUCTIONS

1.0 Important information

In order to ensure complete and effective

operation and for your own safety, all of the

following instructions should be read carefully

and observed.

This document should be regarded as part

of the product and as such should be kept

accessible and durable to ensure the safe

operation of the fan. All product-related

safety regulations must be observed.

These installation instructions cannot

take all installation, operating and

maintenance conditions into account. You

can obtain further information from your local

dealer or the product data sheet, which can

be downloaded on the internet.

1.1 SAFETY INSTRUCTIONS

Special regulations apply for use,

connection and operation; consultation

is required in case of doubt. Further

information can be found in the relevant

standards and legal texts.

mThe following points must be

observed before any cleaning,

maintenance and installation work:

• Isolate device from the mains power

supply and secure against being

switched on again!

•After switching off, a waiting time

of 5 min. must be observed, as

dangerous voltages may be present

after disconnection from the mains due

to internal capacitors!

•Non-observance, touching live electrical

parts or improper use of this power

supply unit can result in death, serious

injuries or significant material damage.

•All product-related safety reg.must be

observed! Further country-specific

regulations must also be observed.

1.2 Application

This compact, fully encapsulated switching

power supply is solely designed as a

decentral power supply for the Uno hab unit for

installation in a flush-mounted box.

Further information can be found in section 3.0

“Installation”.

– Normal use:

The Uno hab PSF power supply unit is only

approved for fixed installation inside buildings in

a flush-mounted box. The maximum permissible

ambient temperature can be found on the type

plate.

– Reasonably foreseeable misuse:

The power supply unit is not suitable for

operation under difficult conditions, such as

high levels of humidity, aggressive media,

long standstill periods, heavy contamination,

excessive loads due to climatic, technical or

electronic influences. The same applies for the

mobile use of fans (vehicles, aircraft, ships,

etc.). Usage under these conditions is only

possible with approval from Airflow, as the

standard version is not suitable in this case.

– Improper, prohibited use:

Any use other than the intended use is not

permitted! The conveying of solid matter or

solid matter content > 10µm in air and liquid is

not permitted!

1.4 Personnel qualication

m DANGER!

The electrical connection and start-up must only

be carried out by qualied electricians.

Installation, servicing and maintenance of the

fan must only be carried out by qualified

electricians. Uno hab individual room ventilation

units can be used by children over the age of

8 as well as persons with physical, sensory,

or mental disabilities or lack of experience

and knowledge, if they are supervised or

instructed with regard to the safe use of the

unit and they understand the resulting risks.

Children must not play with the unit. Cleaning

or user maintenance must not be carried out by

unsupervised children.

1.4 Scope of delivery

The delivery includes the switching power supply

Uno hab PSF / Part Number: 90000996

2.0 Warranty claims – exclusion of liability

If the following instructions are not observed, our

warranty shall be invalidated. The same applies

to liability claims against Airflow. The use of

accessory parts, which are not recommended

or offered by Airflow, is not permitted. Any

possible damages are not covered by the

warranty.

2.1 Certicates - guidelines

If the product is installed correctly and used to its

intended purpose, it conforms to all applicable

EU guidelines at its date of manufacture.

2.2 Shipping

The power supply unit is packed ex-works

in such a way that it is protected against

normal transport strain. Carry out the shipping

carefully. It is recommended to leave the power

supply unit in the original packaging until

required.

2.3 Receipt

The shipment must be checked for damage and

correctness immediately upon delivery. If there

is any damage, promptly report the damage

with the assistance of the transport company.

If complaints are not made within the agreed

period, any claims could be lost.

3.0 Installation

-During operation, the power supply unit must

not be accessible.

- A suitable flameproof casing must be

provided in the end product.

-Sufficient cooling must be ensured.

-The maximum surface temperature must not

be exceeded.

The casing fulls the requirements of IP 67 and

it is fully protected against dust and penetrating

humidity.

The power supply units are intended for

installation in deep (61 mm) ush-mounted

boxes with a 68 mm diameter (re resistance

850°C according to VDE 0606).

The connection can be made via the connecting

wires with suitable terminals.

Connecting cables:

Input side: 0.8 mm² (black - white) with outer

sheath, wire end ferrule

Output side: 0.52 mm² (black - red) tin-plated

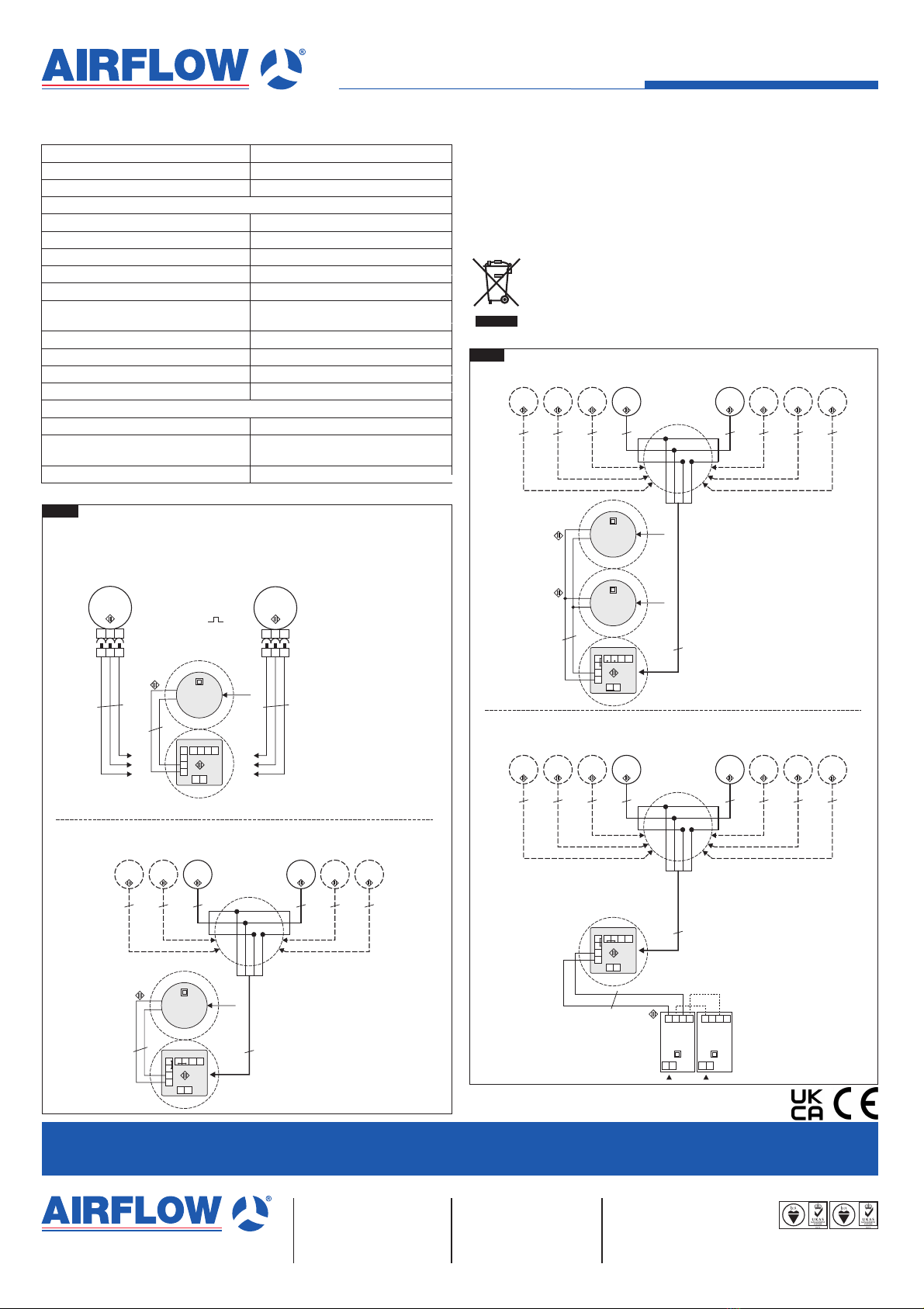

3.1 Electrical connection / start-up

mDANGER

Touching live parts will result in electric

shock. Only connect with no voltage

present!

–The electrical connection and initial start-up

are to be carried out in accordance with the

relevant wiring diagrams and are only to be

carried out by a certified electrician.

–The relevant standards, safety

regulations (e.g. DIN VDE 0100, EN

50178), as well as the technical

connection conditions of energy suppliers

are to be adhered to!

–A multipole mains section switch/isolator, with

a minimum contact opening of 3 mm (VDE

0700 T1 7.12.2 / EN 60335-1) is mandatory!

–The power supply and the supply network

must be sufficiently fused.

–The network connection must comply with

IEC 62103, EN 50178 and IEC 60364, VDE

100

– Network configuration, voltage and frequency

must be consistent with the rating plate

information.

–The supply cable must be introduced, so

that no water can get in along the cable in

case of water exposure.

–Never work on the power supply unit when it is

live! There is a risk of electric arcs and electric

shock which can result in death, serious

injuries or significant material damage.

m Warning:

Dangerous voltages and components with

signicant amounts of stored energy may

be present during normal power supply unit

operating conditions. However, they are not

accessible.

Improper use can result in electrical shock

or significant burns! Keep away from fire

and water!

The power supply unit must be connected

according to wiring diagram SD-3 (1 power

supply unit), or SD-4 (2 parallel power

supply units) depending on the conguration.

m Attention!

A ferrite is mounted on the output side of

the power supply unit. This is a component

of the power supply unit and it is required

to ensure correct functionality. The ferrite

must not be removed.

The input and output cables must be installed

so that they are clearly separated from one

another (see Fig. 1). Ideally, position the ferrite

at a distance of approximately 1 cm behind the

power supply unit. Install the cables without

twisting. The cables must not cross each other

and must be shortened accordingly.

All wiring terminals must comply with DIN EN

60998. These terminals must be designed for

a temperature range from 85 °C and a voltage

of 300 V.

Terminal recommendation: Wago Type 221

Fig.1