MIG-29 FULCRUM by AK Models.

10

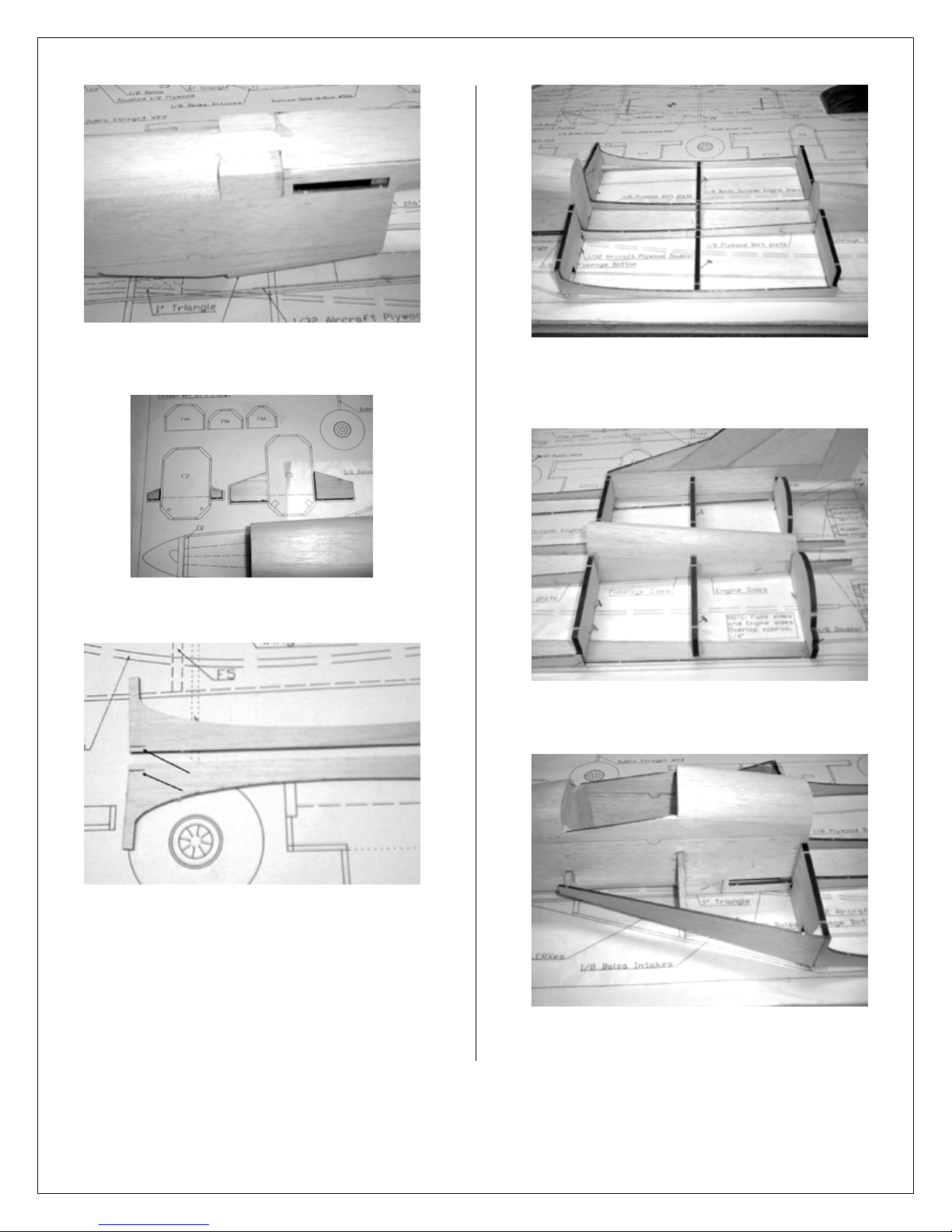

• Glue 2” long 1/4x3/8 hatch rail to F8 (let hatch stick out a

little); also trim F9 so hatch can be lowered to match sides

(see picture above). Install hatches and drill holes for

mounting screws (two in front and one at rear). Screw

hatches down and sand to make a good transition.

• Take previously cut off fuse extensions and place them

next to tail cone wire opening, try-fit 1/8 rear sheeting.

Trim as needed and glue in place, extensions and

sheeting.

• Use building pin to mark through openings for rudder

torque-rods. Make 1/4 opening with rotary tool working

from the bottom of stabilizer.

• Take rear part of vertical fin and cut groove to epoxy

torque-rod. Bend rods as per plans and lubricate as you

did before. Place them in epoxy filled groove, pin it to

wax paper covered BB, fold wax paper over and pin scrap

wood next to epoxy groove. It will hold epoxy in place

giving you good surface. Push rods toward the scrap

wood and place 1/8 shims under the rod to help it center

in epoxy Let it dry 15-20 min. and move rods to brake

them loose from epoxy.

• While epoxy is curing, take a ruler and mark a straight

line to help locate positioning of the torque-rod assembly.

• Epoxy torque-rod assembly in place keeping it tight to

vertical fin and stabilizer. Also, make sure you pin it in

place vertical to stabilizer.

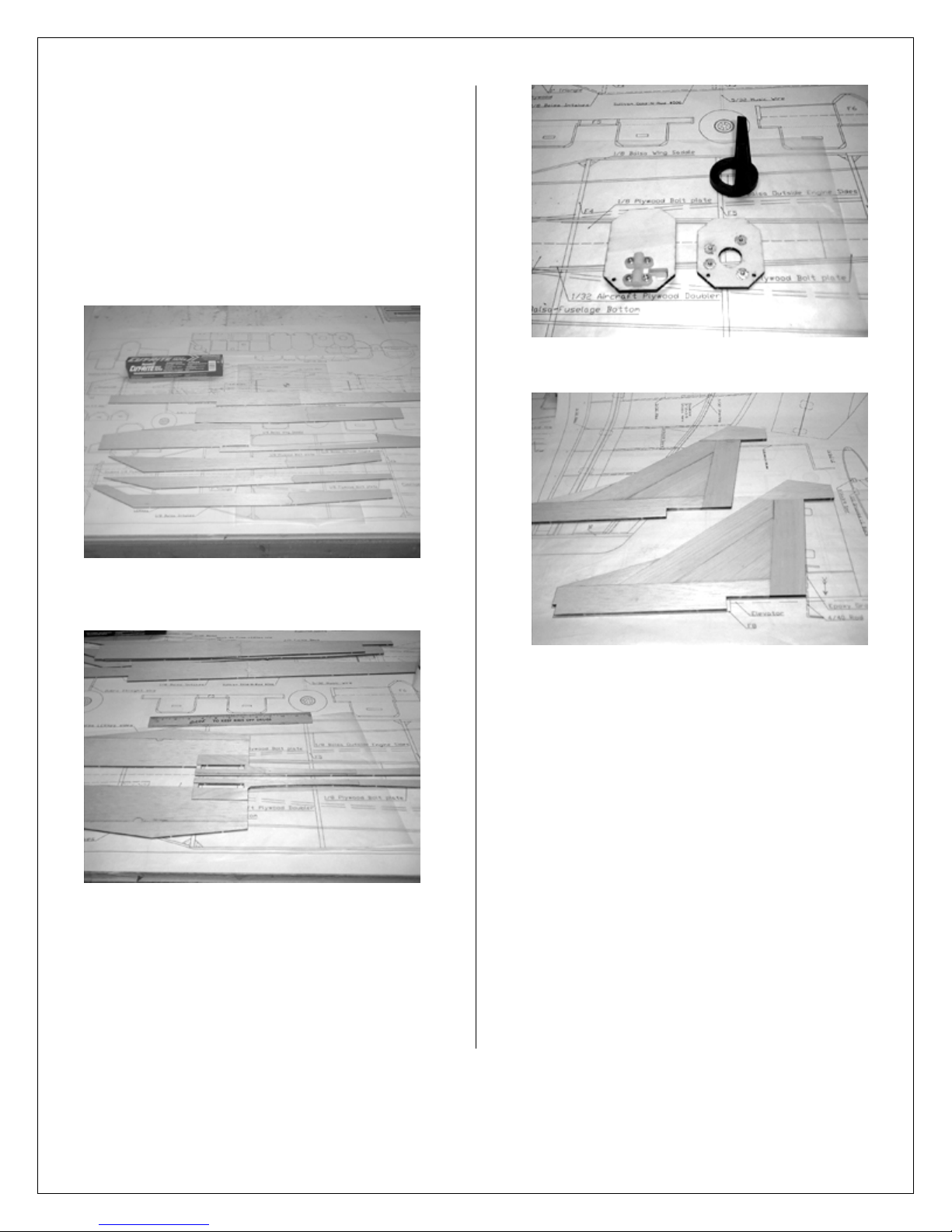

• Plank sheet tail pipes. You will need 36 strips 7- 1/2”

long 1/8 x 5/16. It is very simple if you follow few rules.

Start from the bottom; glue one strip at a time. Tip:

always glue it first to F8 until you come to angle ended

strips (you would want to place all strips half way on to

F8 and keep them aligned, except bottom row). Second:

tack glue it in the middle and finally to F9. Third: Use CA

accelerator to move along faster. Do not worry about

small imperfections at this time, you will correct it later.

• Once angled strips needed, place them over the area, mark

and cut. Then push slightly in tack glue angled end and

then glue to F8.