3

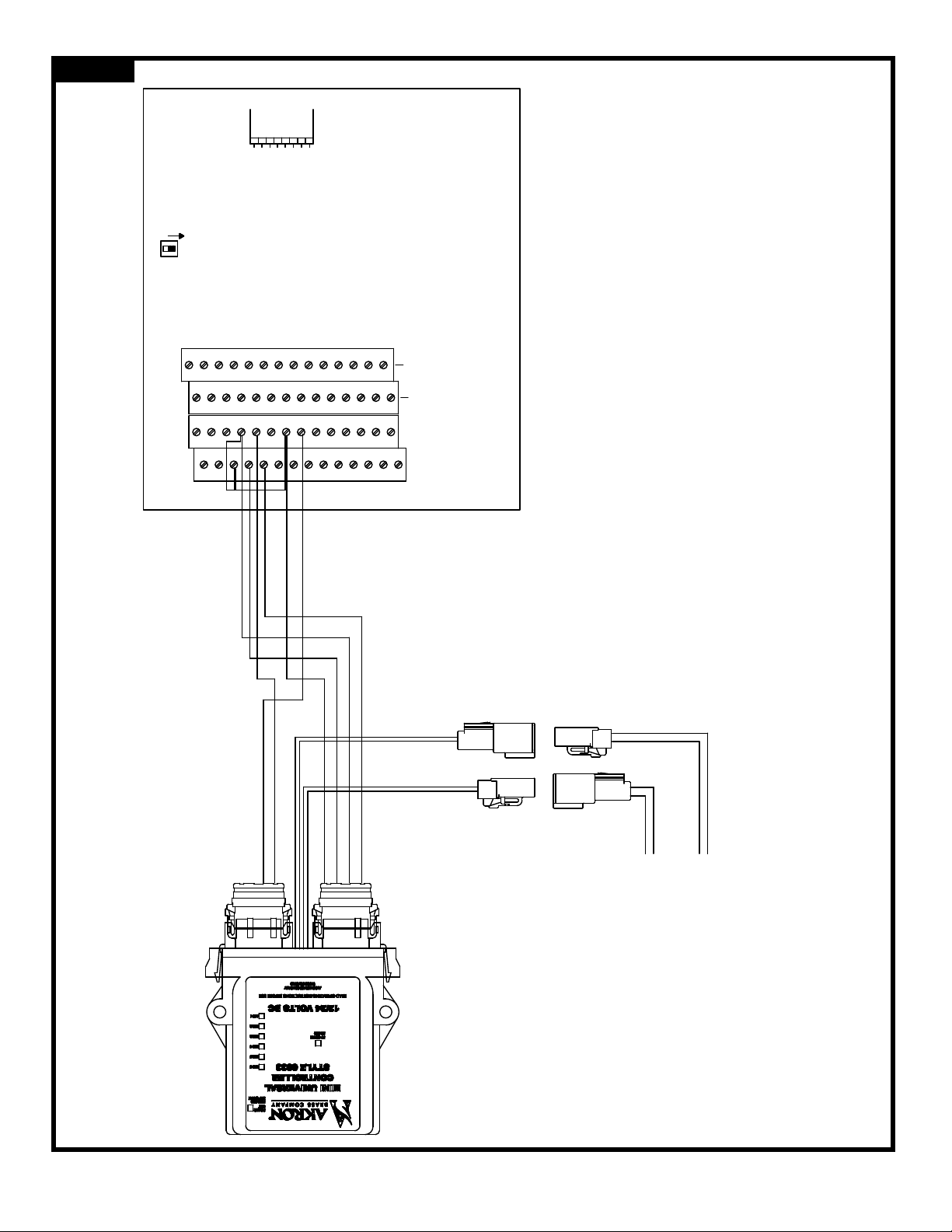

DeckMaster with Position Feedback, All StreamMasters (Universal 1 Logic Box)

Note:ThesoftwarefortheDeckMasterwithPositionFeedbackandalloftheStreamMastersdoesnotsupportthe

ElectricRiser.TheElectricRisermustbeusedinstand-alonemodewithitsowndedicated“Extend/Retract”

toggle switch.

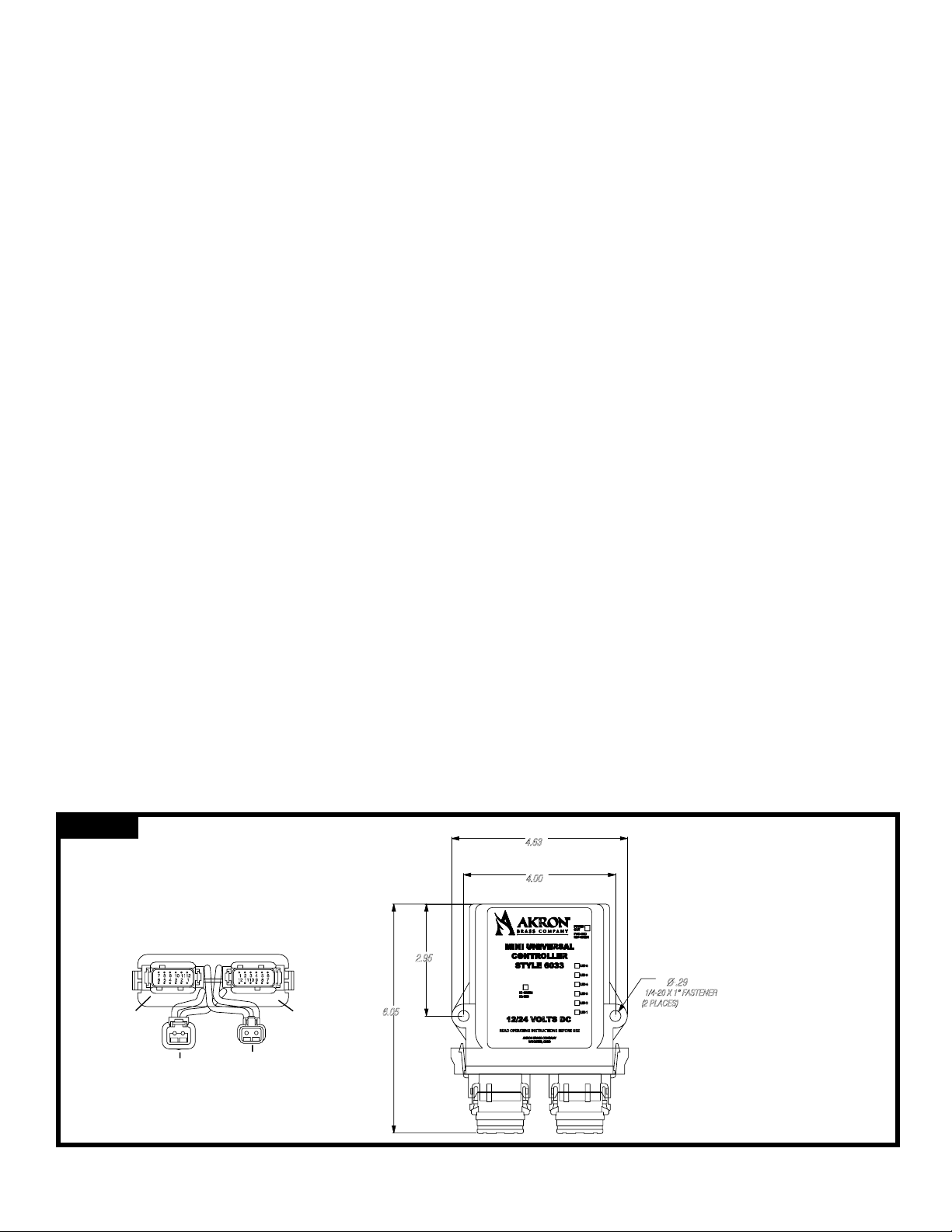

A. Connect an EXTEND/RETRACT toggle switch to the 6033 Mini Universal Controller

(1)UseanSPDTmomentarystyletoggleswitchwherethecenterpositionisoff.

(2)ConnecttheswitchCOMMONterminaltotheblackconnector(righthandsideof6033),positionnumber1.

(3)ConnecttheswitchRETRACTterminaltotheblackconnector,positionnumber2.

(4)ConnecttheswitchEXTENDterminaltotheblackconnector,positionnumber3.

B. Connect power to the DTP04-2P receptacle connector on the 6033 Mini Universal Controller

• 12AWGRedWireis+SystemVoltage(12or24VoltsDC)

• 12AWGBlackWireisSystemGround

• Useappropriatefuseorcircuitbreakertoprotectwiring

• Thevoltageratingonthemotormustmatchthesystemvoltage.

C. Optionally connect the Retracted/Extended Indicator Relays on the 6033 Mini Universal Controller

• FullyRetractedRelay:ThisrelayturnsonwhentheRiserisFULLYRETRACTED.Also,theK1-GREENLED

(Middlefrontof6033)willturnon.Thedryrelaycontactsarelocatedatpositions9and10ofthegray

connector(leftsideof6033),andareratedat1ampmaximum@30VDC.

• FullyExtendedRelay:ThisrelayturnsonwhentheRiserisFULLYEXTENDED.Also,theK2-REDLED(Middle

frontof6033)willturnon.Thedryrelaycontactsarelocatedatpositions11and12ofthegrayconnector(left

sideof6033),andareratedat1ampmaximum@30VDC.

Universal II Logic Box

A. Connect to CAN network using AB cable #721594.

B. Follow the set VP procedure for the monitor that you are using.

C. Enable the Electric Riser in the set-up menu.

• ErrorCode2-1indicatesthattheriserfunctionisenabled,buttheriserisnotavailableonthenetwork.

OPERATING INSTRUCTIONS

WARNING: Be sure to completely deploy the Riser/Monitor before flowing water.

DeckMaster with Prox Switches (No Position Feedback) – “Automatic Mode”

• Deploy:LiftthesafetycoverontheDEPLOY/STOWswitch,pushthetoggleswitchupandthenrelease.The

RiserwillextendtolifttheDeckMasterup12”andthentheDeckMasterwilldeploy.

• Stow:LiftthesafetycoverontheDEPLOY/STOWswitch,pushthetoggleswitchdownandthenrelease.

TheDeckMasterwillstowandthentheRiserwillretract.

• EmergencyStopduringDeployorStow:IfitisnecessarytoimmediatelystoptheRiser/DeckMasterduring

thedeployorstowsequence,activateanyswitchonthecontrolpanelandtheunitwillstopmoving(E-Stop).

Tocompletethedeployorstowsequenceafteranemergencystop,presstheDEPLOYorSTOW

switch again.

DeckMaster with Position Feedback, All StreamMasters – “Stand-Alone Mode”

• Deploy:PressandholdtheEXTENDswitchuntiltheRiserisfullyextended,andthenreleasetheEXTEND

switch.LiftthesafetycoverontheDEPLOY/STOWswitch,pushthetoggleswitchupandthenrelease.The

monitorwilldeploy.

• Stow:LiftthesafetycoverontheDEPLOY/STOWswitch,pushthetoggleswitchdownandthenrelease.

Themonitorwillstow.PressandholdtheRETRACTswitchuntiltheRiserisfullyretracted,andthenrelease

theRETRACTswitch.

• EmergencyStopduringDeployorStow:IfitisnecessarytoimmediatelystoptheMonitorduringthedeploy

orstowsequence,activateanyswitchonthecontrolpanel(exceptEXTEND/RETRACT)andtheunitwillstop

moving(E-Stop).Tocompletethedeployorstowsequenceafteranemergencystop,presstheDEPLOYor

STOWswitchagain.

Manual Override Control: Themanualoverrideistobeused,onlywhenthepowertotheRiserisoff.Toraisethe

Riser,apply50PSIofwaterpressureanditwillgoup.Tolower,turnoffwater,pullthepinatthetopofthe

actuator and lower monitor and riser.

Note: Youwillhavethefullweightoftheriserandmonitor.Itwouldbebesttousemorethanoneperson.

Itwillalsohelptolifetthemonitorandriserasyoupullthepin.