WARNING: Although the circuit board includes a water-resistant coating, it is important to keep water out

of the control box and logic box. Prolonged exposure to water will cause damage.

WARNING: When the cover of the control box or logic box is removed, check that the O-ring under the

cover is intact and free of dirt and debris.

WARNING: The StreamMaster monitor uses current limiting for both the monitor and nozzle. Use only

appropriate Akron Brass Company nozzles.

WARNING: Do not use the electric controls when the override cranks are being used or are in position for use.

WARNING: Make the connection of the vehicle and auxiliary battery the final step.

WARNING: Replace the identification tags if they should become worn or damaged.

WARNING: DO NOT exceed the maximum pressure or flow ratings of the monitor. Exceeding these

ratings may lead to an injury or may cause damage to the monitor.

WARNING: DO NOT install shutoffs on the outlet of the monitor. Shutoffs increase the potential for

pressure surges due to water hammer, which have the potential to cause an injury or damage

to the monitor.

WARNING: The StreamMaster monitor, nozzle, logic box, control box, tether controller, and field

adjustable stops are made for optimal performance. Do not alter in any manner.

WARNING: The StreamMaster monitor was designed for use with the Akromatic nozzle. Use of any other

nozzle could affect the speed or operation of the unit and should be tested before being put

into service.

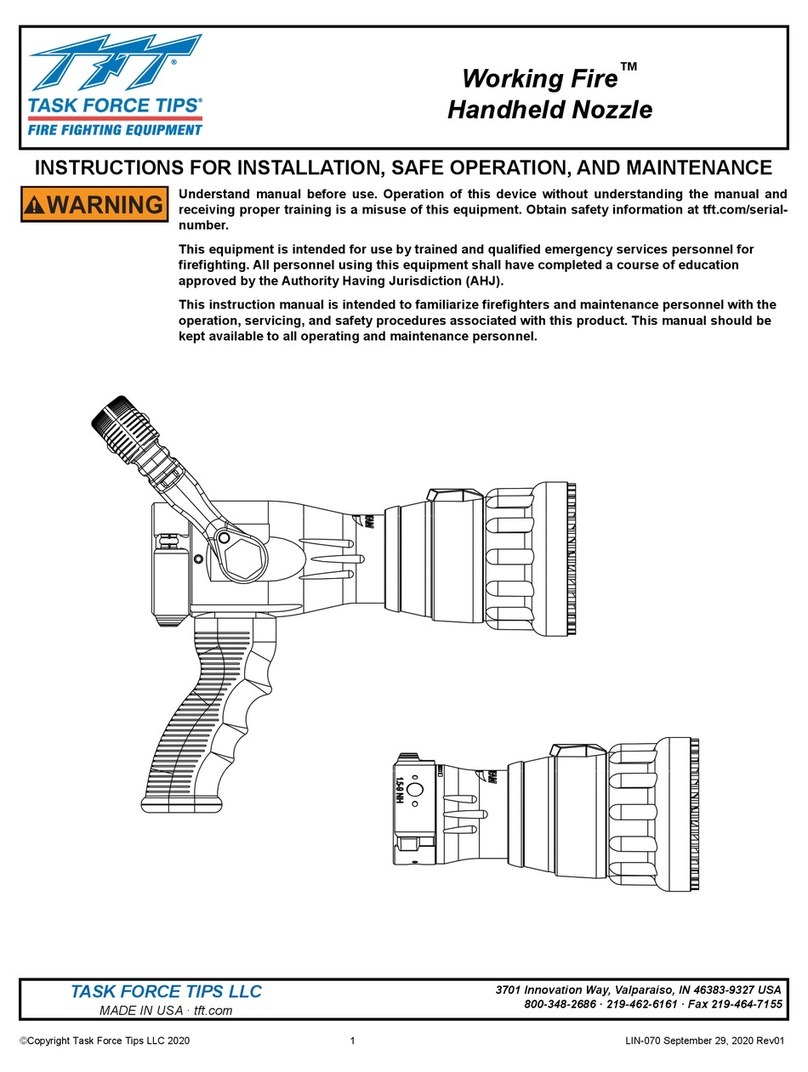

WARNING: The StreamMaster monitor contains moving parts. Keep hand, finger and objects away

from pinch points (Figure 1).

WARNING: Disconnect power and disable flow before maintenance.

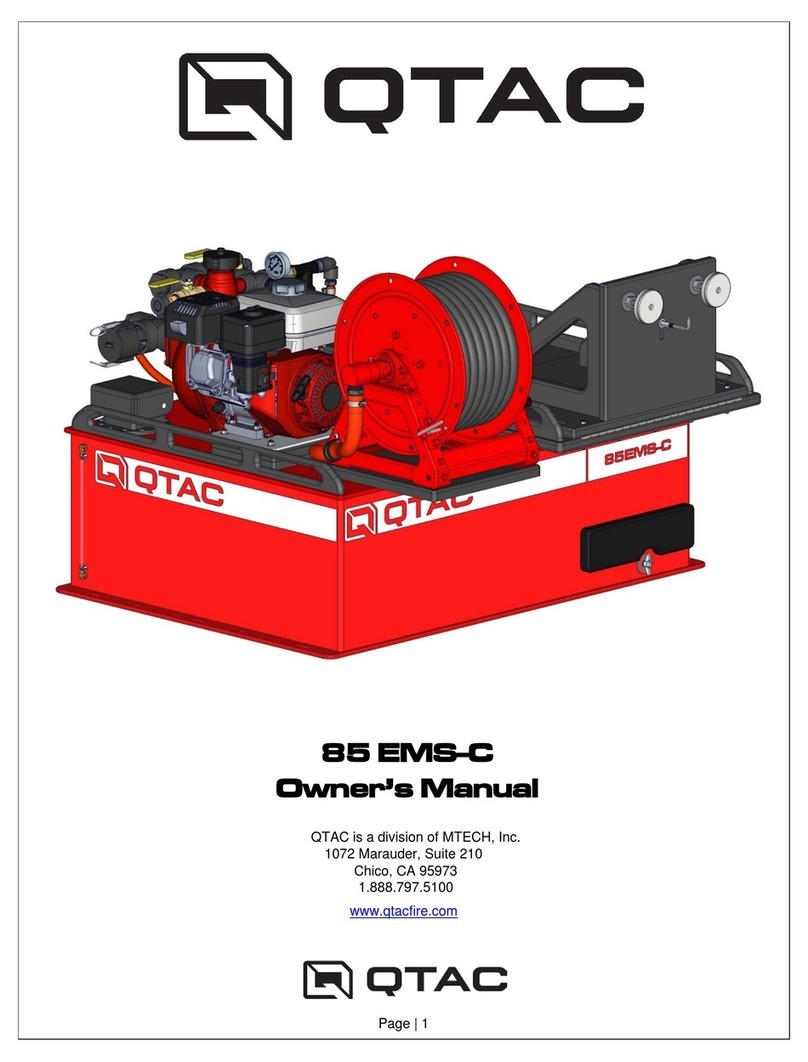

WARNING: Keep all personnel out of the Danger Zone (Figure 2), in front of the outlet of the monitor when

the water source is attached. Dangerous flow velocities can cause serious injury.

WARNING: Not designed for explosive environments.

GENERAL INSTRUCTIONS

•Review the instructions, wiring diagram, component layout and rotational stops diagram before

installing this unit. This unit operates on 12 volt DC or 24 volt DC depending on the unit chosen. All

electrical current flows through the wires. The monitor does not act as a ground. The wires from the

control boxes can be cut to the length for the application plus 10 inches (See STEP 2). Do not extend

the wires from the logic box to the monitor.

•The optional auxiliary battery is used for power failures and to ensure that the proper voltage and current

are maintained at the logic box when using a smaller gauge wire (12 Awg) for the power leads (vehicle

battery). If the optional auxiliary battery is used, do not extend the auxiliary battery wires. This will ensure

that the proper voltage and current are maintained at the monitor for it to operate properly. The optional

battery is automatically recharged by the truck electrical system through the positive (auxiliary battery) and

ground connections on the circuit board (Figure 6). The vehicle battery connections must have power

turned on whenever the truck is running so that the battery can be recharged properly. If possible,

connect the positive (vehicle battery) wire directly to the main vehicle battery or main master switch. A

diode in the logic box will prevent the optional auxiliary battery from feeding current back into the main

truck system.

•Not recommended for use in salt water applications.

•For firefighting by trained firefighters only.

•For use with water or standard fire fighting foams only. After use with foam, flush with fresh water.

•Do not use the StreamMaster nozzle as a forcible entry tool.

•Drain the StreamMaster monitor and nozzle after use to prevent “freeze damage”.

•Ensure that the thread in the nozzle swivel matches the thread on the StreamMaster outlet. Do not

overtighten the nozzle onto the StreamMaster.