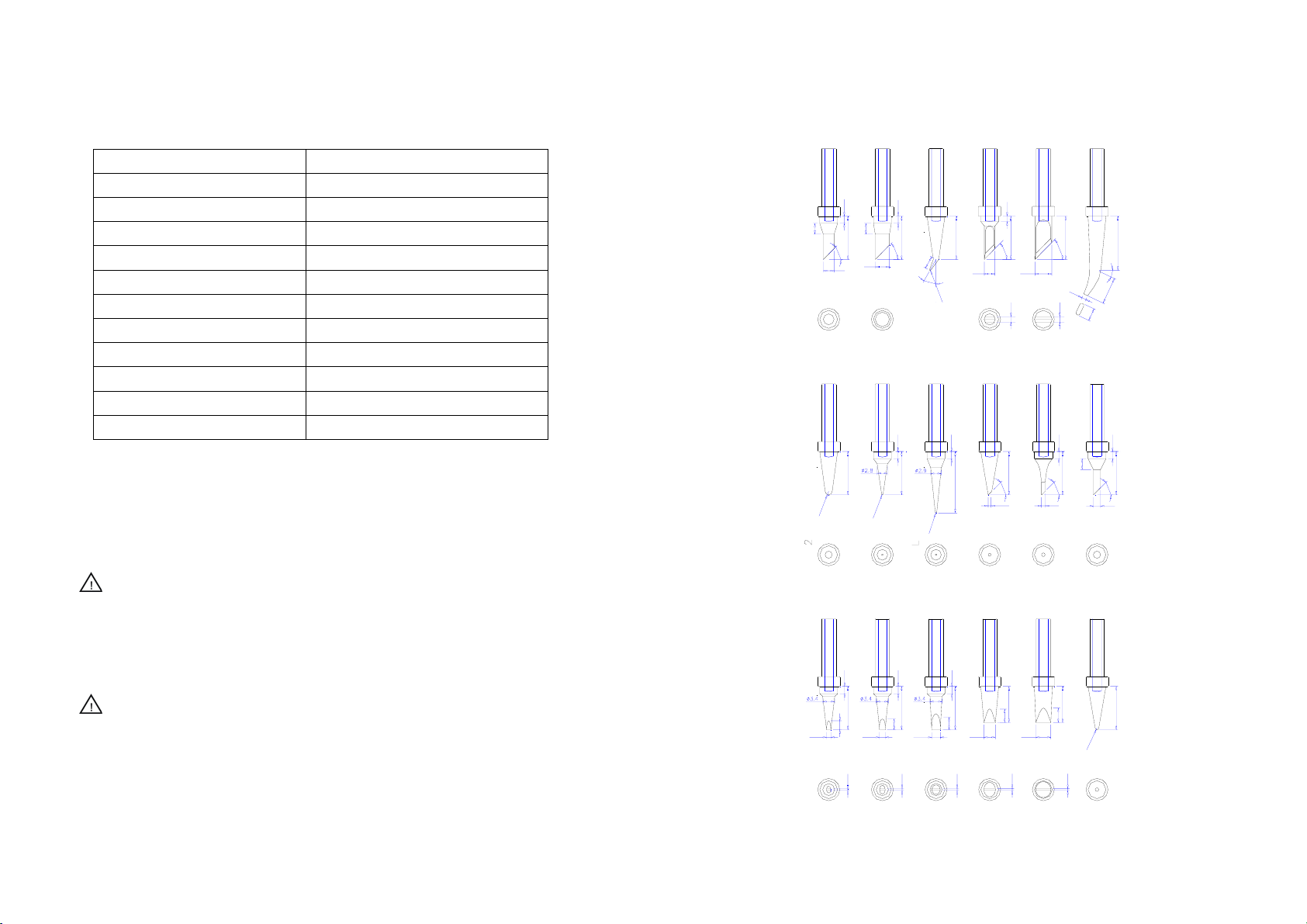

6.2.1 Inspect and Clean the Tip

Caution: Never file the tip to remove oxide.

1. Set the temperature to 250℃.

2. When the temperature stabilizes, clean the tip with the cleaning sponge and

check the condition of the tip.

3. If there is black oxide on the solder-plated portion of the tip, apply new solder

(containing flux) and wipe the tip on the cleaning sponge. Repeat until the

oxide is completely removed. Coat with new solder. The solder protects the

tip from oxidation and prolongs the life of the tip.

4. If the tip is deformed or heavily eroded, replace it with a new one.

6.2.2 A De-tinned Tip

1. Why a “de-tinned” tip fails to work?

A de-tinned tip is one which cannot wet with solder. This exposes the plating to

oxidation and degrades the heat transfer efficiency of the tip.

2. The de-tinning is caused by:

1) Failure to keep the tip covered with fresh solder while not in use.

2) High tip temperatures.

3) Insufficient melting in soldering operations.

4) Wiping the tip on dirty or dry sponges and rags. (Always use a clean, wet,

industrial grade, sulfur-free sponge.)

5) Impurities in the solder, iron plating, or on the surfaces to be soldered.

6.2.3 To Restore a De-tinned Tip

Remove the tip form the solder handle and allow the tip to cool down.

Use the “▲”and “▼” button to change displayed value. Set the

password value in the same way described in “temperature setting”. After

selecting the password of three digit, press the“ON/OFF”button.

zThe input password is error

5. If the iron enters into normal work state after display shows the current

setting temperature for two seconds, this indicates the input password is

error, and the temperature setting can’t be done.

zThe input password is correct

6. If the window shows , this indicates the inputting password is

correct. After displaying about 4 seconds, it comes into the normal work

state, and the temperature setting and parameter setting will be admitted.

zInput new password

7. When display window is showing , press the“ON/OFF”button, and

shows , it indicates the iron comes into inputting new password

state. Press “▲”and “▼” button to change displayed value. See

“temperature setting”.

zRepeat the new password

8. When three digits are selected, press“ON/OFF”button, the display

window shows , again. Now input the new password once again.

Repeat the same steps.

9. If the latest two passwords are the same, pressing“ON/OFF”button will

modify the password successfully. The new password is stored into the

memory.

10. If the latest two passwords are not the same, pressing“ON/OFF”button,

and the display window shows , it needs to rewrite new password.

(See the last 8~9 step). The changing of password is successful until the

latest two passwords are the same.

Note:

zThe word of password is 0 to 9, ten figures. If not, the input password is

invalid.

zBecause the password of the two work stations is one and only, after setting

the password of one station, the parameter setting of other station is locked

too.

Page 8

Page 11