©2004 PACE Inc., Annapolis Junction, Maryland

All Rights Reserved Page 8 of 17

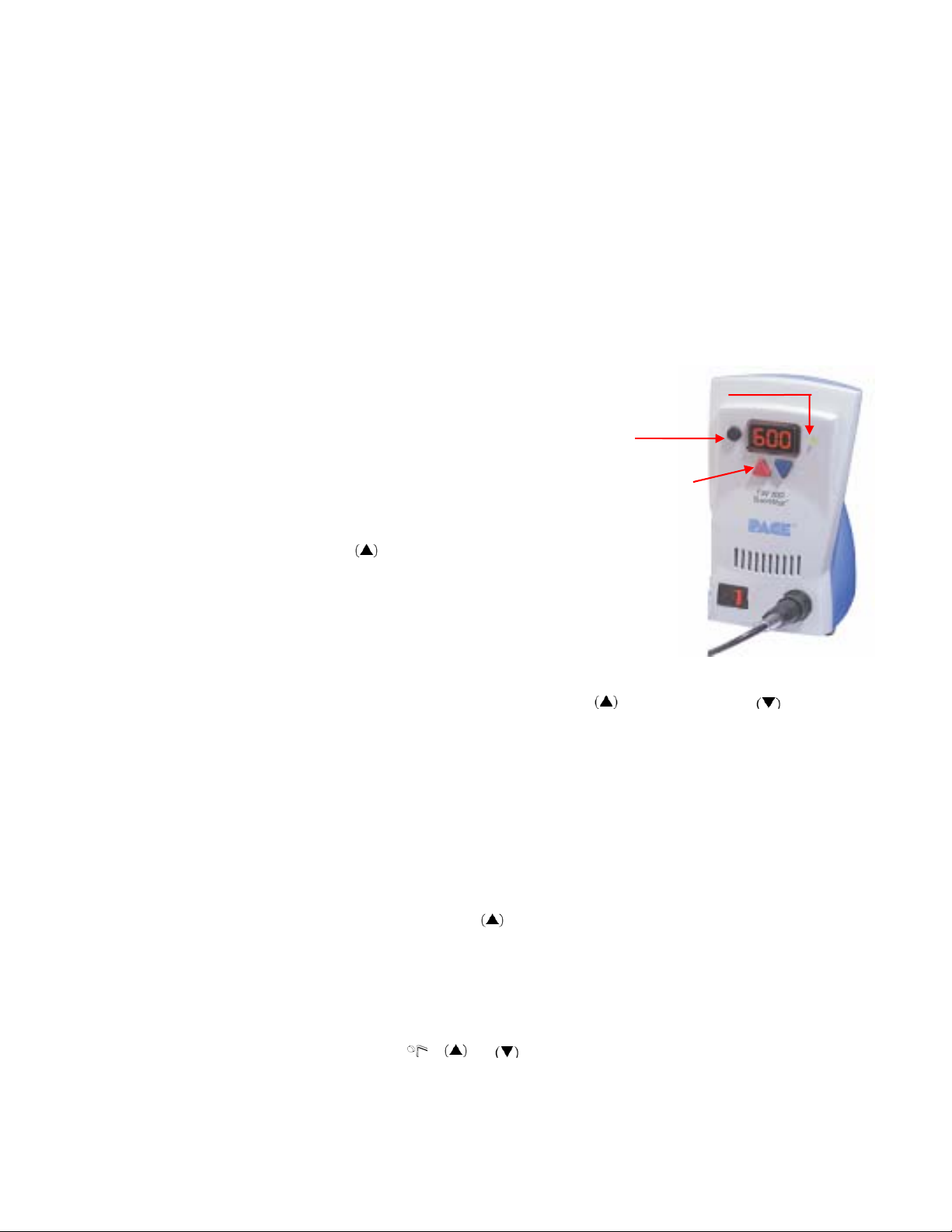

Program/

Menu Button

4. Once the tip has reached the desired heat level, the LED indicator will turn green and the

system is ready to use.

The HW 100 system comes standard with an Auto-Setback and Auto-Off Features. These are pre-

programmed for 30 minute SetBack and 30 minute Auto Off, which can be turned off by the switch on

the bottom of the unit. When Setback mode has been entered, the heat level will be adjusted to 3.5.

Setback can be exited by either thermally shocking the tip by placing it in a dampened sponge or by

simply switching the unit off for a brief moment. Auto Off can be reset by switching unit off then on.

TW 100 TempWise System

The TW 100 system is very easy to adjust and operate. The following instructions detail system

features and operation of the system. Information regarding changing of system options (e.g.,

Temperature Setback time, Auto Off) is contained in the "Programming Your System" portion of this

manual.

1. Ensure that the Set-Up procedure has been performed.

Verify the following:

a) Handpiece connection to the power source.

b) Proper tip installed in handpiece.

c) Power cord connection between an appropriate

AC supply and the power source.

2. Turn the Power Switch On ("I"). The display will begin

to increase as the TD 100 handpiece heats up.

3. Press the Scroll Up Key. The Set Temperature is now

displayed, immediately perform step 4.

NOTE: If a Password has been previously programmed into the

system, "EP" will be appear on the LED Display at this point.

When this message appears, the operator must enter the

correct Password before adjusting the temperature.

4. Adjust the temperature by pressing and holding Scroll Up Key or Scroll Down key.

Observe the display as the Set Temperature increases first in increments of 5°, then in

increments of 10°. When the desired temperature is reached, release the key.

NOTE: The Set Temperature can only be within the set temperature limits. If the lower limit

is reached, the display will read off. If the upper limit has been reached, the display

will read “HiL”. Temperature limits can be adjusted in the programming menu. See

“Programming Your System” section.

5. Observe the Digital Readout as the temperature reaches and stabilizes at the Set Tip

Temperature.

6. The system can be manually forced into Temperature Setback by pressing and holding

the Scroll Down (t) Key and the Scroll Up Key.

7. When the display begins to blink, the system is in Temperature Setback mode and will

reduce the set temperature to 177°C (350°F). NOTE: If Auto Off has been enabled in

the programming menu, the system will enter Auto Off (temperature Off and LED Display

flashing "Off") after the preset time of handpiece inactivity. Auto Off can be exited by

pressing any key.

8. To exit Temperature Setback mode, perform any one of the following:

a) Press and release a Key ( ,or ). This is the preferred method.

b) Wipe the hot handpiece tip on a wet sponge to thermally load the tip.

c) Turn the Power Switch Off ("0") and then back on ("I").

LED

Indicator

Scroll Up/Down

Buttons