GAS FILLING

Fill only in a well ventilated area.

The soldering iron runs on butane gas such as

used with ordinary cigarette lighters. A small

amount of liquid gas should be visible through

the gas inspection window, gas vapour alone

will not generate sufficient pressure. Do not

overfill.

lMake sure the on/off switch is in the

“O” (off) position before filling.

lHold unit vertically with the filling valve

upwards. Push the gas re-fill cylinder down

onto the filling valve. The flow of gas from the

re-fill cylinder to the soldering iron depends

on gravity (See fig. 2).

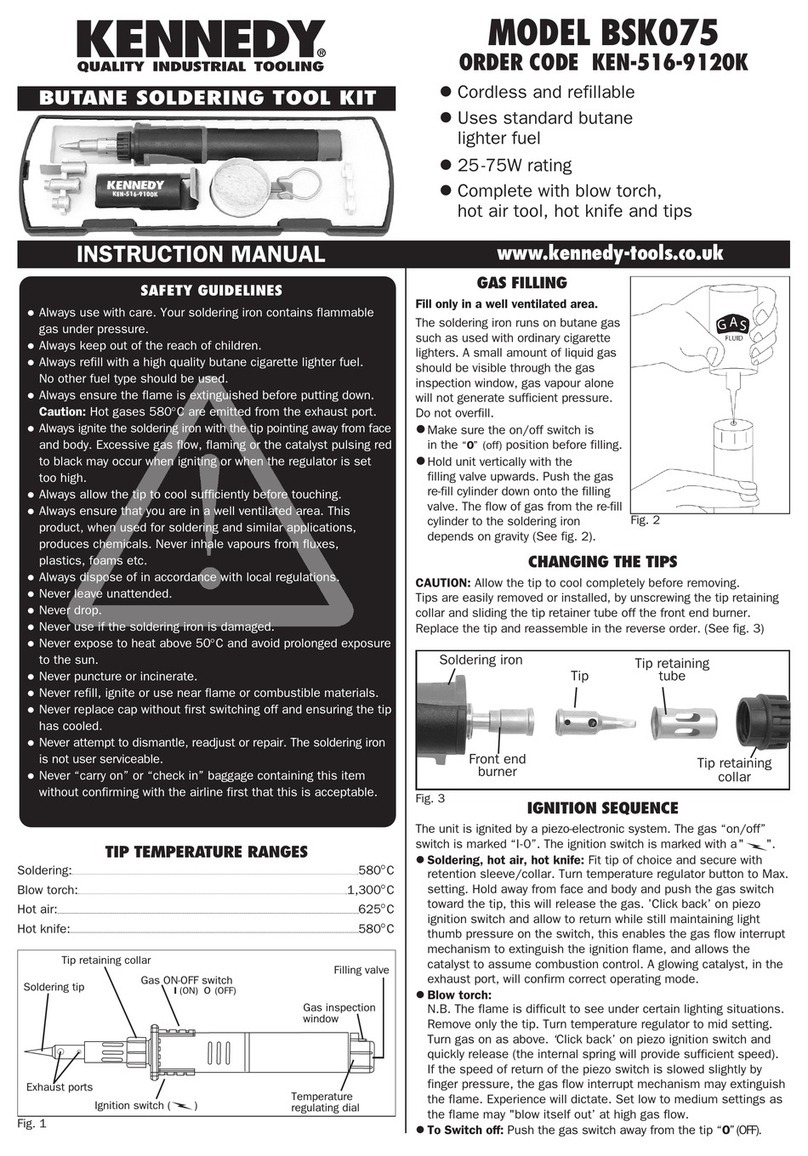

CHANGING THE TIPS

Tips are easily removed or installed, by unscrewing the tip retaining

collar and sliding the tip, tip retaining tube off the front end burner.

Replace the tip and reassemble in the reverse order (See fig. 3).

IGNITION SEQUENCE

The unit is ignited by a piezo-electronic system. The gas “on/off”

switch is marked I-0. The ignition switch is marked with a" ".

N.B. Only one 2.4mm soldering tip is provided with this soldering iron.

loldering, hot air, hot knife: Fit tip of choice and secure with

retention sleeve/collar. Turn temperature regulator button to Max.

setting. Hold away from face and body and push the gas switch

toward the tip, this will release the gas. 'Click back' on piezo

ignition switch and allow to return while still maintaining light

thumb pressure on the switch, this enables the gas flow interrupt

to extinguish the ignition flame, and allows the catalyst to

assume combustion control. A glowing catalyst, in the exhaust

port, will confirm correct operating mode.

lBlow torch:

N.B. Flame is difficult to see under certain lighting situations.

Remove only the tip. Turn temperature regulator to mid setting.

Turn gas on as above. ‘Click back’ on piezo ignition switch and

quickly release (the internal spring will provide sufficient speed). If

the speed of return of the piezo switch is slowed slightly by finger

pressure, the gas flow interrupt mechanism may extinguish the

flame. Experience will dictate.

Set low to medium settings as the flame may "blow itself out' at

high gas flow.

lTo witch off: Push the gas switch away from the tip “O” (OFF).

BUTANE SOLDERING TOOL

www.kennedy-tools.co.uk

lCordless and refillable.

lUses standard butane

lighter fuel.

lEqual to 25-125W.

lTemperature range 580°C.

lCan also be used as a blow torch.

SAFETY GUIDELINES

lAlways use with care. Your soldering iron contains flammable gas under

pressure.

lAlways keep out of the reach of children.

lAlways refill with a high quality butane cigarette lighter fuel.

No other fuel type should be used.

lAlways ensure the flame is extinguished before putting down.

Caution: Hot gases 580°C (1,075°F) are emitted from the exhaust

port.

lAlways ignite the soldering iron with the tip pointing away from face

and body. Excessive gas flow, flaming or the catalyst pulsing red to

black may occur when igniting or when the regulator is set

too high.

lAlways allow the tip to cool sufficiently before touching.

lAlways ensure that you are in a well ventilated area. This product, when

used for soldering and similar applications, produces chemicals. Never

inhale vapours from fluxes, plastics, foams etc.

lAlways dispose of in accordance with local regulations.

lNever leave unattended.

lNever drop.

lNever use if the soldering iron is damaged.

lNever expose to heat above 50°C (120°F) and avoid prolonged

exposure to the sun.

lNever puncture or incinerate.

lNever refill, ignite or use near flame or combustible materials.

lNever replace cap without first switching off and ensuring the tip has

cooled.

lNever attempt to dismantle, readjust or repair. The soldering iron is not

user serviceable.

lNever “carry on” or “check in” baggage containing this item without

confirming with the airline first that this is acceptable.

IN TRUCTION MANUAL

Fig. 2

TECHNICAL SPECIFICATION

ength (with cap): ........................................................................230mm

Weight (no gas, with cap & tip): ........................................................143g

Operating Time (depending on setting):..........................................60 mins

Wattage (equivalent): ..................................................................25-125W

Refill time (typical): ................................................................10 seconds

Gas refill type: ..............................................................Butane lighter fuel

Ignition: ................................................................................Piezo igniter

Igniter life (typical):..............................................................50,000 cycles

Safety cut-off switch: ..........................................................................Yes

Temperature adjustable: ....................................................................Yes

Approval: ..........................................................................................TUV

Tip temperature (up to)

Soldering: ......................................................................................580°C

Blow torch (not included):..............................................................1,300°C

Hot air tip (not included):..................................................................625°C

Hot knife (not included): ..................................................................580°C

MODEL BS125

ORDER CODE KEN-516-9300K

Gas inspection

window

Filling valve

Fig. 1

Ignition switch ( )

Temperature

regulating dial

Gas ON-OFF switch

I(ON) o (OFF)

Soldering tip

Exhaust ports

Tip retaining collar

Fig. 3

Soldering iron

Front end

burner

Tip

Tip retaining

tube

Tip retaining

collar