AK4000 Ethernet Product Family 1 Document 180-0008-001 R08

Part # Description CLEI Code Kit Part # Description

AK400C CO Ethernet line card, 50 Mbps at CSA, Line powering VAUIAG8J AK4000C CO Ethernet Kit (AK400C & AK100S)

AK401C CO Ethernet line card, 50 Mbps at CSA VAUIAG9J AK4001C CO Ethernet Kit (AK401C & AK100S)

AK400R RT Ethernet line card, 50 Mbps at CSA VAUIAHAJ AK4000R RT Ethernet Kit (AK400R & AK100S)

AK410C CO Ethernet line card, 25 Mbps at CSA, 45 Mbps max, Line powering VAUIACWJ AK4010C CO Ethernet Kit (AK410C & AK100S)

AK411C CO Ethernet line card, 25 Mbps at CSA, 45 Mbps max VAUIACXJ AK4011C CO Ethernet Kit (AK411C & AK100S)

AK410R RT Ethernet line card, 25 Mbps at CSA, 45 Mbps max VAUIACYJ AK4010R RT Ethernet Kit (AK410R & AK100S)

AK420C CO Ethernet line card, 10 Mbps at CSA, 20 Mbps max, Line powering VAUIAFZJ AK4020C CO Ethernet Kit (AK420C & AK100S)

AK421C CO Ethernet line card, 10 Mbps at CSA, 20 Mbps max VAUIAF0J AK4021C CO Ethernet Kit (AK421C & AK100S)

AK420R RT Ethernet line card, 10 Mbps at CSA, 20 Mbps max VAUIAF1J AK4020R RT Ethernet Kit (AK420R & AK100S)

AK100S 1RU Shelf (w/ AK100F fan module) VAMB410F

The AK4000 Ethernet product family enables point to point transport of Ethernet services over bonded pairs of copper, optimized

for CSA distances (9kft 26AWG or 12kft 24AWG). The AK4000 family consists of Ethernet Central Office and Remote cards

that plug into a 1RU high housing for 19” and 23” racks and for wall mounting. The remote card is either line powered by the

Central Office card or locally powered. Aktino products utilize a technology “MIMO on DMT” which uses coordinated signal

processing over multiple transceivers to achieve significant performance improvements over standard DSL technology. Refer to

the AK4000 Ethernet Technical Practice (180-0007-001) for more comprehensive information and troubleshooting.

Installation is identical for both the CO and RT ends.

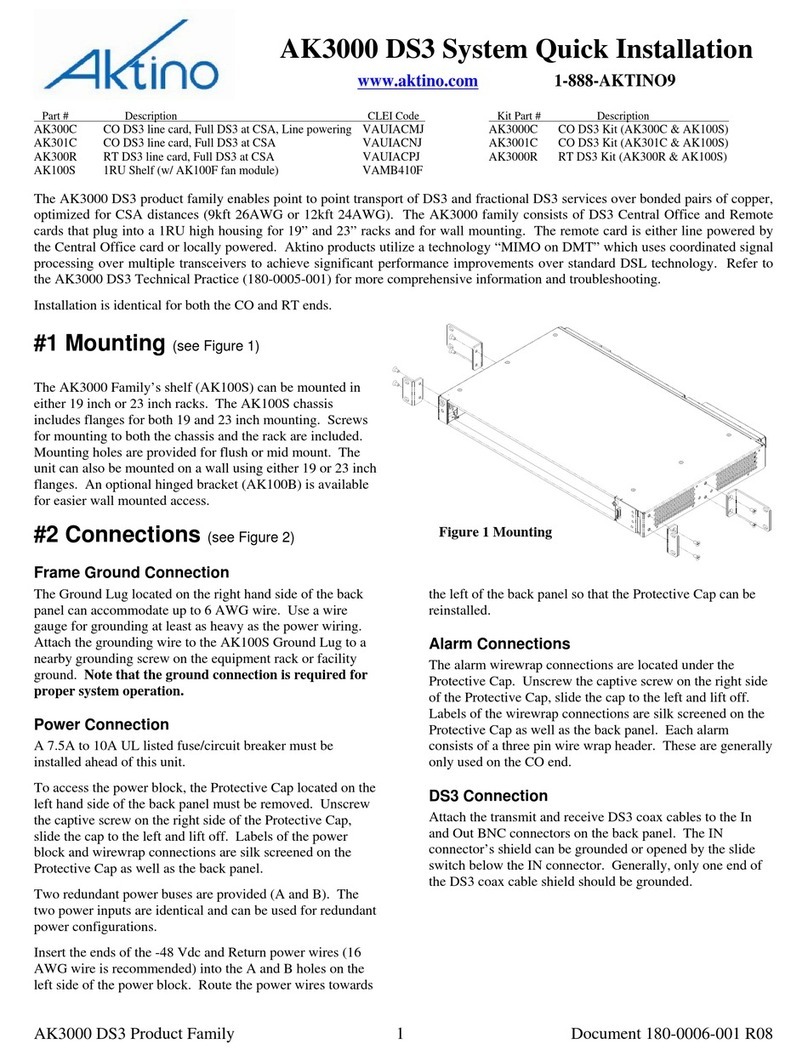

#1 Mounting (see Figure 1)

The AK4000 Family’s shelf (AK100S) can be mounted in

either 19 inch or 23 inch racks. The AK100S chassis

includes flanges for both 19 and 23 inch mounting. Screws

for mounting to both the chassis and the rack are included.

Mounting holes are provided for flush or mid mount. The

unit can also be mounted on a wall using either 19 or 23 inch

flanges. An optional hinged bracket (AK100B) is available

for easier wall mounted access.

#2 Connections

Frame Ground Connection (see Figure 2)

The Ground Lug located on the right hand side of the back

panel can accommodate up to 6 AWG wire. Use a wire

gauge for grounding at least as heavy as the power wiring.

Attach the grounding wire to the AK100S Ground Lug to a

nearby grounding screw on the equipment rack or facility

ground. Note that the ground connection is required for

proper system operation.

Power Connection (see Figure 2)

A 7.5A to 10A UL listed fuse/circuit breaker must be

installed ahead of this unit.

To access the power block, the Protective Cap located on the

left hand side of the back panel must be removed. Unscrew

the captive screw on the right side of the Protective Cap,

slide the cap to the left and lift off. Labels of the power

block and wirewrap connections are silk screened on the

Protective Cap as well as the back panel.

Two redundant power buses are provided (A and B). The

two power inputs are identical and can be used for redundant

power configurations. Insert the ends of the -48 Vdc and

Return power wires (16 AWG wire is recommended) into

the A and B holes on the left side of the power block. Route

the power wires towards the left of the back panel so that the

Protective Cap can be reinstalled.

Alarm Connections (see Figure 2)

The alarm wirewrap connections are located under the

Protective Cap. Unscrew the captive screw on the right side

of the Protective Cap, slide the cap to the left and lift off.

Labels of the wirewrap connections are silk screened on the

Protective Cap as well as the back panel. Each alarm

consists of a three pin wire wrap header. These are generally

only used on the CO end.

Ethernet Data Connections (Figure 3)

Attach Ethernet data cables to any of the four 10/100BaseT

RJ45 plugs on the front panel.

Caution To order to comply with the intrabuilding

lightning surge requirements, intrabuilding Ethernet wiring

must be shielded, and the shield for the wiring must be

grounded at both ends.

AK4000 Ethernet System Quick Installation

www.aktino.com 1-888-AKTINO9

Figure 1 Mounting