KEENAN MechFiber400+ Operator’s Manual Rev H02 Feb 20237

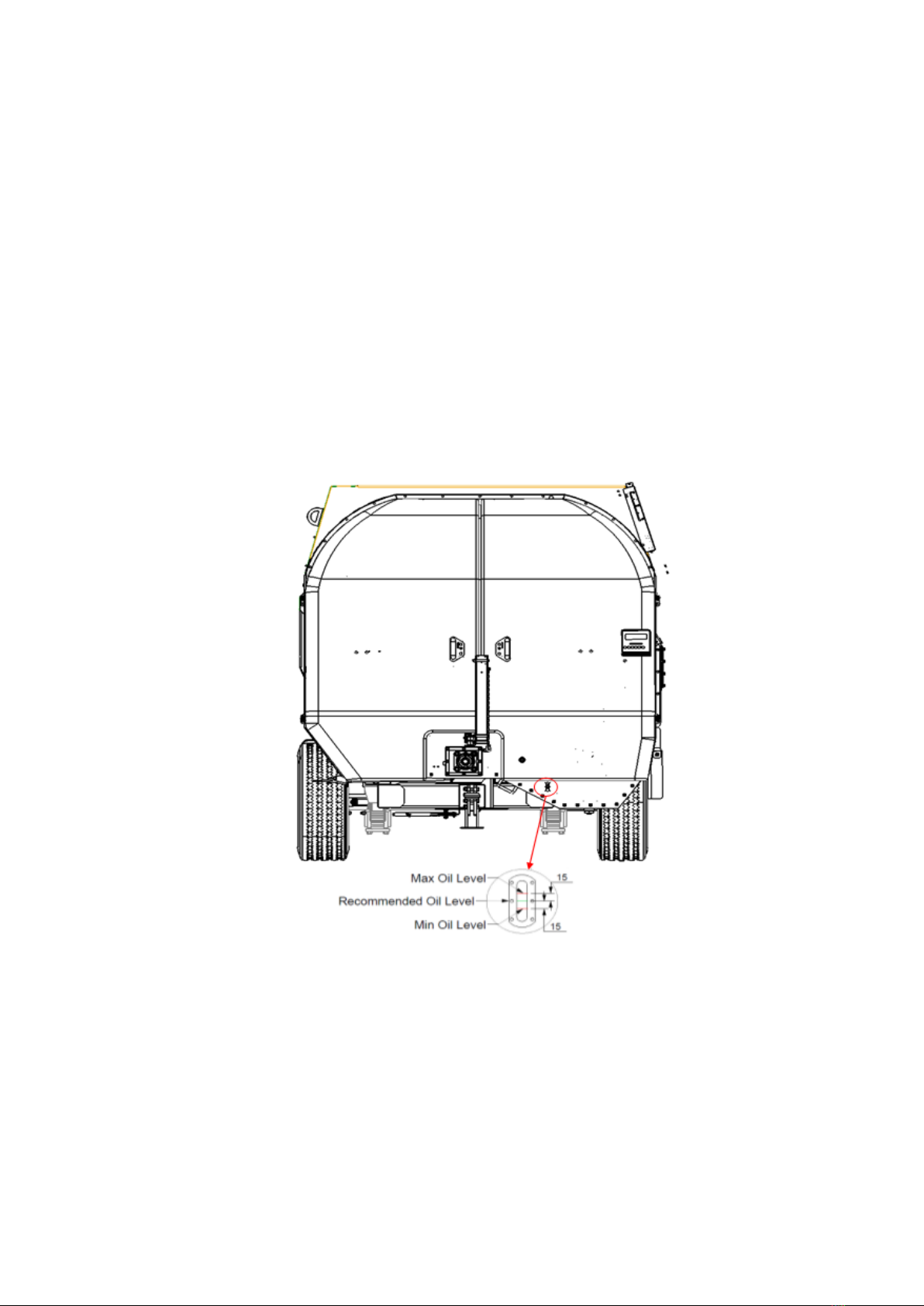

1.4 Oil level

The oil reservoir (or sump) is located on the left side of the drive system. Each day, check the

level of the oil reservoir. Before checking the oil level, ensure that the machine is sitting level

(both front to rear and left to right). An oil-level viewing window has been fitted to the front panel

of the drive system and can be viewed when the front left hand cover is opened. The

recommended oil level should be midway along this window. This represents 28 litres of oil in

the sump. The minimum level is -15 mm from the centre and the maximum level is +15 mm from

the centre.

If the oil level is low, top it up with chain-bar oil (the properties of which allow it cling to the

chains longer). Use Total/Finol Chainac MP if available or a suitable equivalent (volumetric mass

of 879 kg/m3 @ 15°C and viscosity rating of 150mm2/s @ 40°C). Do not use grease on the chains,

as it is unsuitable for the application and will not allow for the lubrication of the vital internal

parts of the chain.

1.5 Chain tensioning

With use, the drive chains will extend slightly over time. To compensate for this, all KEENAN

MechFiber machines are fitted with a tensioner mechanism on the slack side of the chain. The

primary and secondary chain tensioners comprise of a pivoting tension arm connected to a

tension spring and adjusted via a threaded bolt passing through a shoulder plate. The rotor chain

tensioner comprises of a pivoting tension arm connected to a compression spring and adjusted

via a second pivoting arm with locating bolt holes. The auger chain tensioner comprises of a

pivoting tension arm connected to a compression spring via a pull rod and adjusted via a