7 Nov. 2006

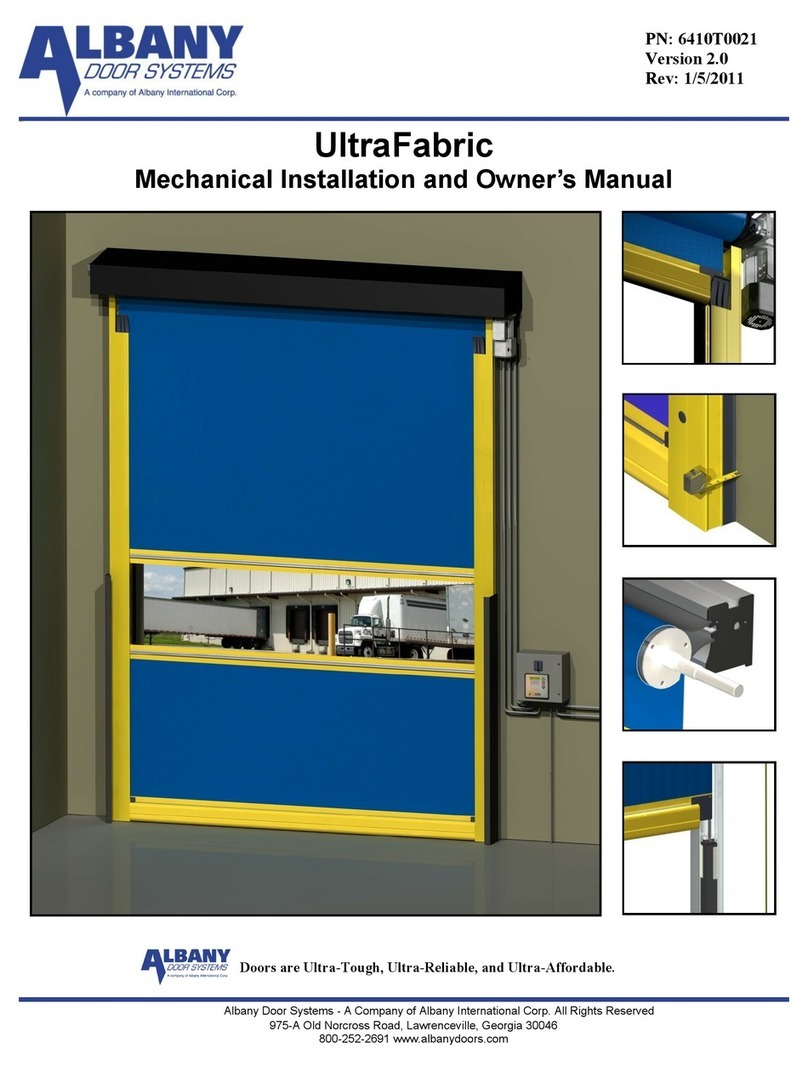

MODEL 355 MECHANICAL INSTALLATION

Step 1

. Unpack crate and inventory parts, comparing against the packing list in the front of this manual,

to verify all parts are on site.

Step 2

. Using a tape measure, determine the clear opening width. Compare this measurement with the

door ordered width. See crate label for door ordered dimensions.

NOTE

THE CLEAR OPENING WIDTH MUST BE THE SAME AS THE DOOR

MANUFACTURED WIDTH IN ORDER FOR THE RESET SYSTEM TO

FUNCTION PROPERLY. THIS MEANS THE DISTANCE BETWEEN

THE SIDE FRAMES AT THE TOP, MIDDLE AND BOTTOM MUST

EQUAL THE DOOR WIDTH.

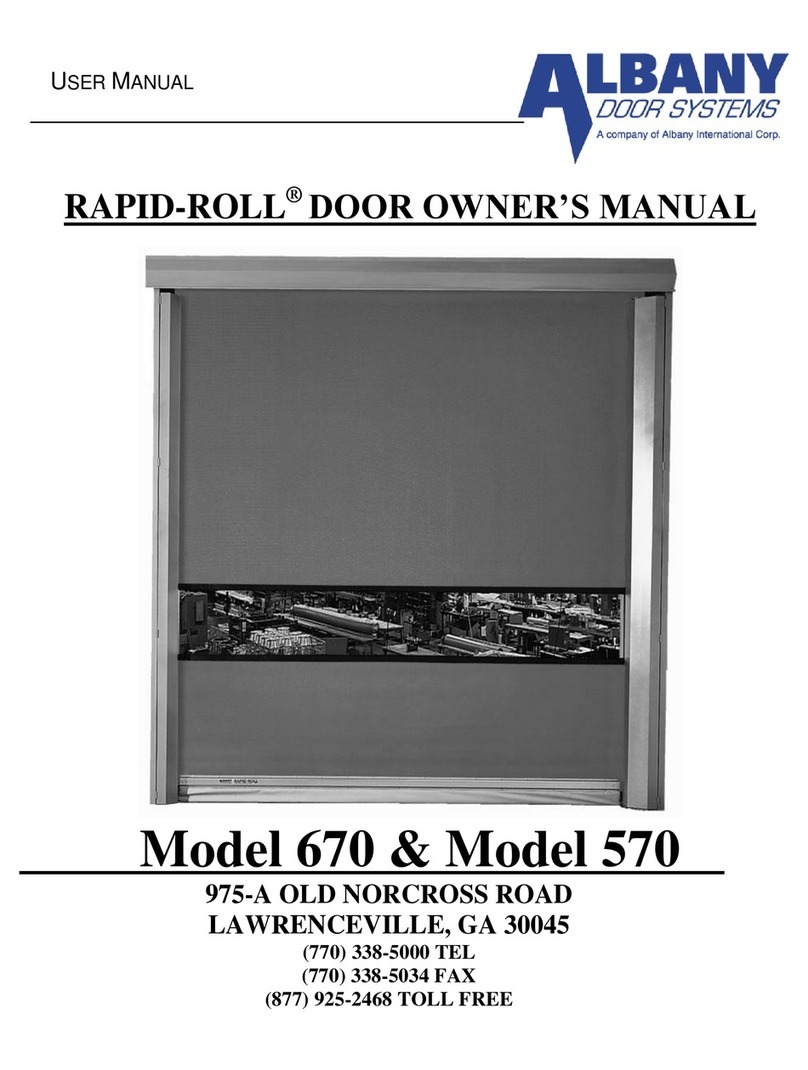

Step 3

.Verify that the opening is

plumb and that the floor slab is

level. Shimming may be required

to level the side columns but no

more then ½”. Refer to approval

drawings for this door to confirm

drive side mounting (left or right-

hand).

Step 4

. Remove the side

columns from crate (one at a

time). Remove covers from both

side columns and set aside.

Remove springs and inner covers

from both side columns. Erect

both columns and place them in

position against the wall with

inner edges in line with the door

jambs. Verify the width per door

specification.

Step 5

. Plumb both side

columns and secure them to the

wall using proper anchoring

hardware. The anchor holes are

slotted to allow for adjustment of

door width and centering over the

door opening. (Figure 1 and

Figure 2)

Slotted Holes

Figure 1