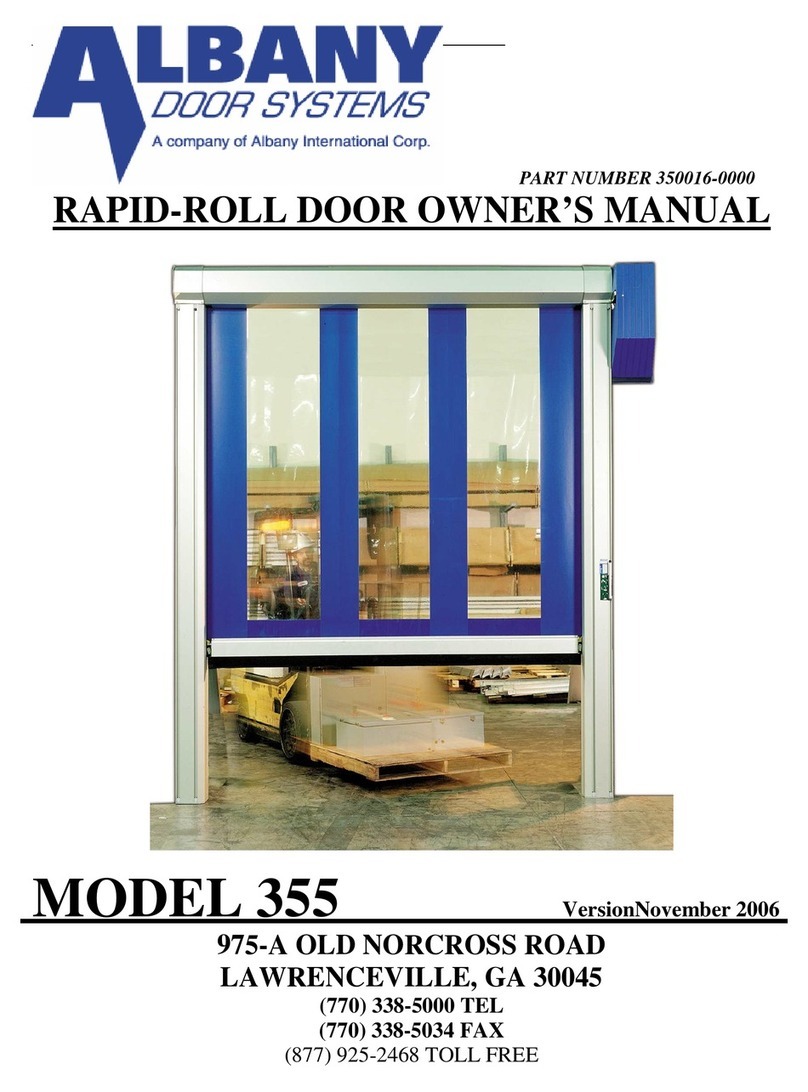

Part Number 6410T0006 Version 4/22/2010

Table of Contents

STATEMENT OF WARRANTY..................................................................Error! Bookmark not defined.

SAFETY PRACTICES ....................................................................................................................................5

PACKING LIST...............................................................................................................................................6

RAPID ROLL® MODEL 570/670 INSTALLATION......................................................................................7

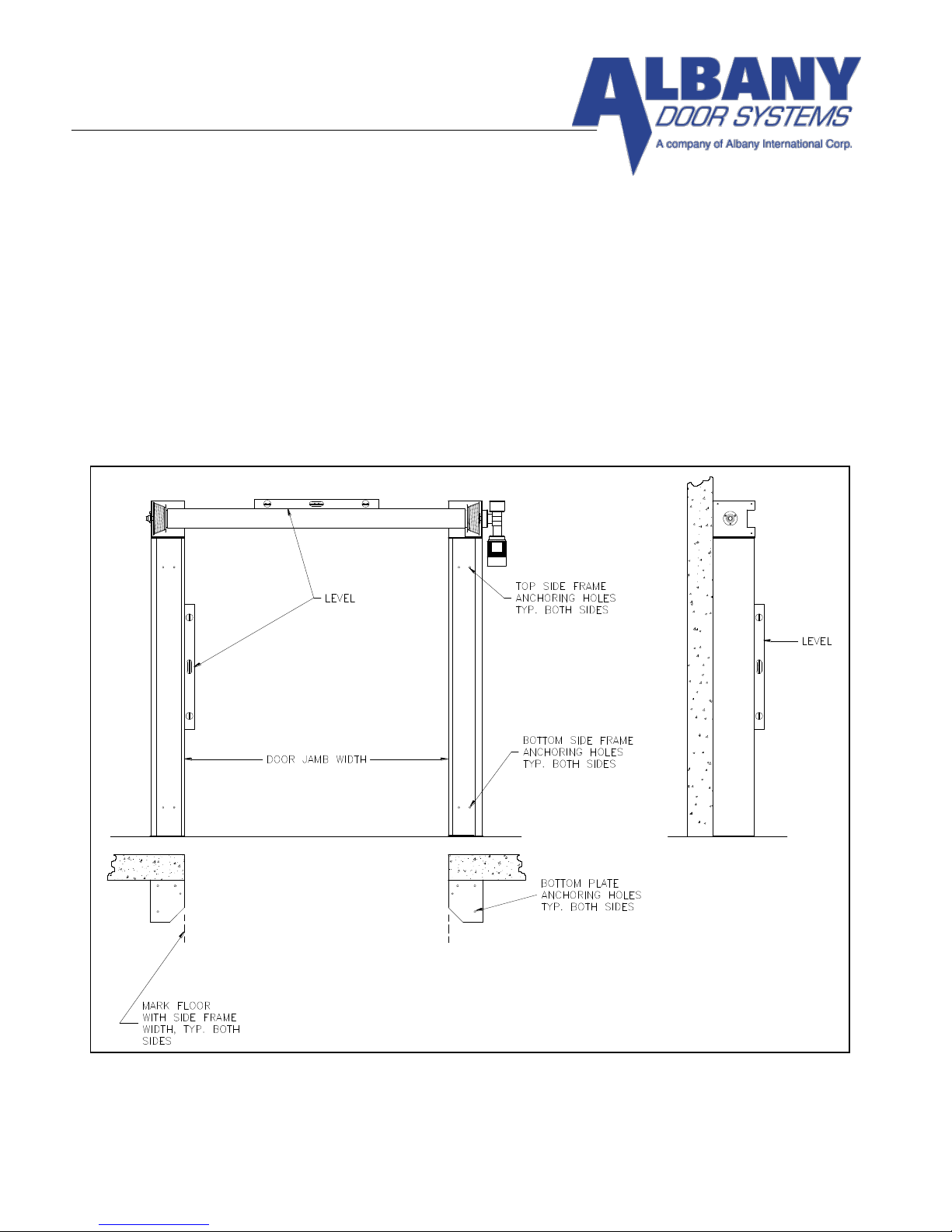

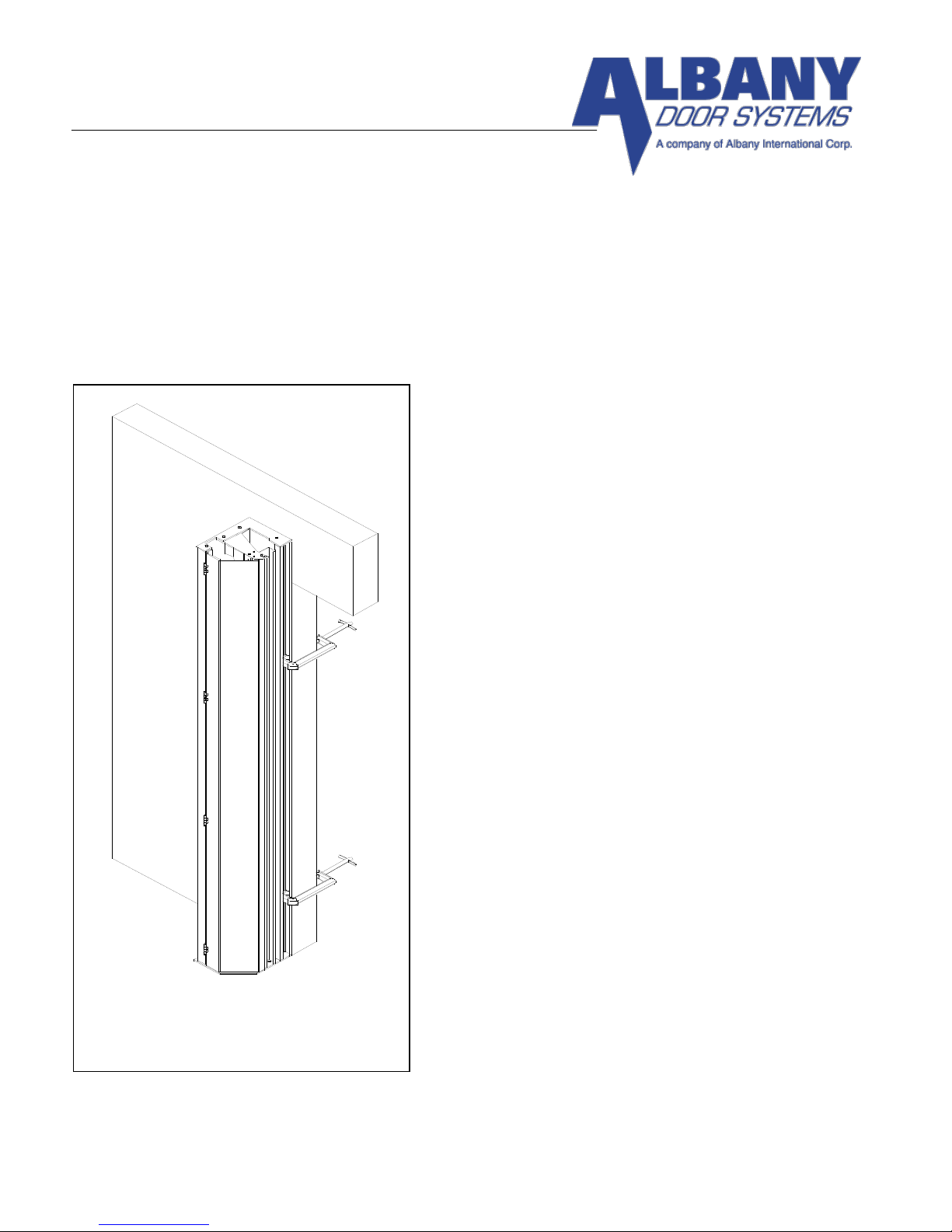

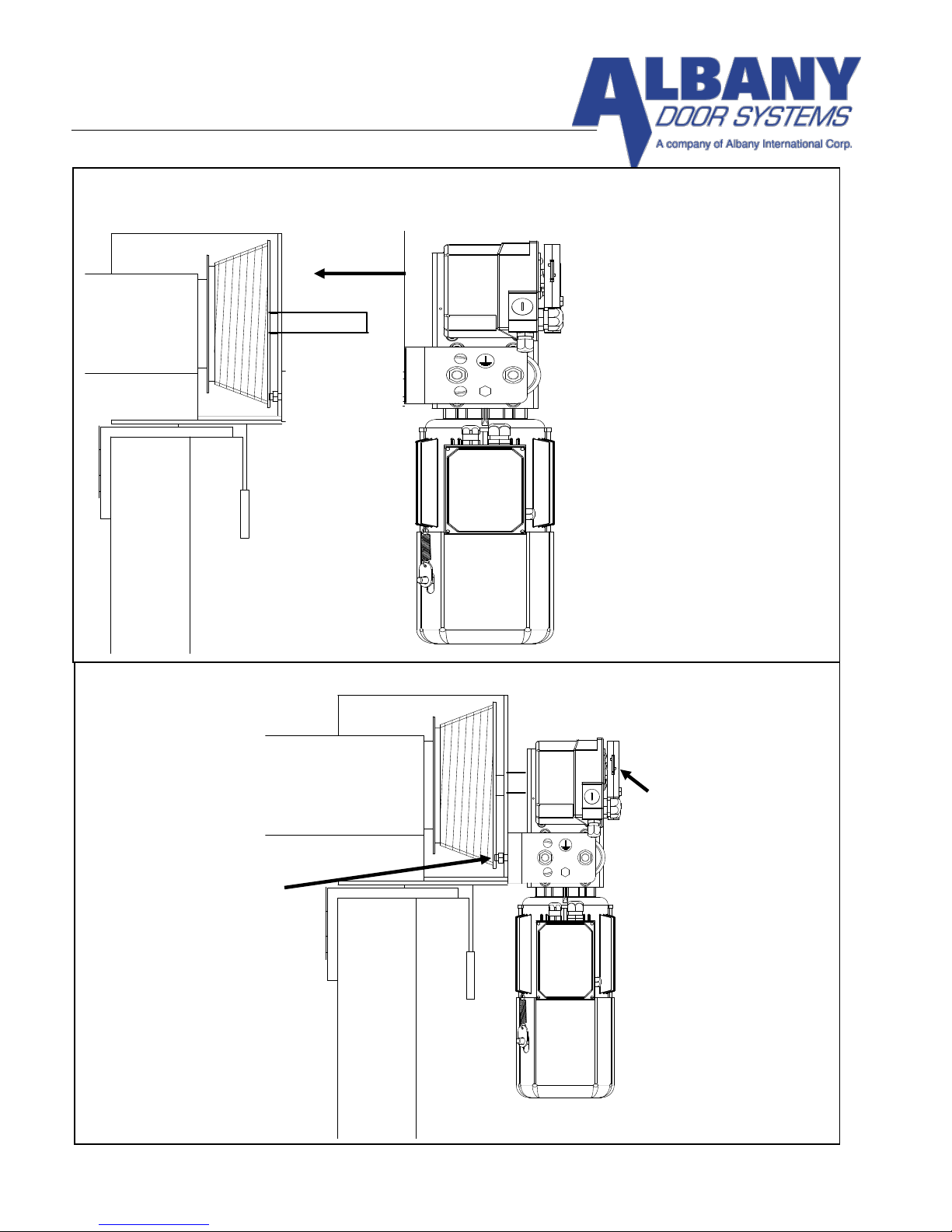

FRAME AND GENERAL INSTALLATION.............................................................................................7

COUNTER-BALANCE SPRING INSTALLATION AND CABLE ROUTING..........................................12

STANDARD BOTTOM BEAM................................................................................................................12

BOTTOM BEAM EQUIPPED WITH SELF-REPAIRING DEVICE™ OPTION. ..................................16

BOTTOM BEAM EQUIPPED WITH RAPID RESET™ OPTION. (Model 670 Only) ..........................19

SPRING TENSIONING AND DOOR BALANCE.......................................................................................19

MAINTENANCE AND INSPECTION.........................................................................................................22

DAILY INSPECTION................................................................................................................................22

QUARTERLY INSPECTION....................................................................................................................22

RAPID ROLL DOOR 570/670 MAINTENANCE CHECKLIST ............................................................23

INSPECTIONS...........................................................................................................................................24

PULLEY INSPECTION.............................................................................................................................26

CABLE DRUM INSPECTION..................................................................................................................26

SELF-REPAIRING DEVICE™ BOTTOM BEAM TYPE .......................................................................26

BRAKE ADJUSTMENT...........................................................................................................................27

OPTION INSTALLATION AND OPERATION ..........................................................................................28

CHAIN DRIVE INSTALLATION.............................................................................................................28

CONTACTLESS SAFETY EDGE™ (C.S.E.) .............................................................................................30

MECHANICAL INSTALLATION............................................................................................................30

ELECTRICAL INSTALLATION..................................................................................................................31

ADJUSTMENTS .......................................................................................................................................32

FULL ROLL COVER & MOTOR COVER INSTALLATION ....................................................................34

FULL VISION PANEL™REPLACEMENT .................................................................................................35

MANUAL DISENGAGEMENT ..................................................................................................................40

MANUAL DISENGAGEMENT ...................................................................................................................41

MANUAL HOIST INSTALLATION............................................................................................................43

MANUAL HOIST WITH DISCONNECT INSTALLATION .....................................................................44

WINDBAR INSTALLATION.......................................................................................................................46

STRAPPED WINDBAR INSTALLATION..............................................................................................46

STRAPLESS WINDBAR INSTALLATION ................................................................................................49

AIR CIRCULATION SYSTEM ....................................................................................................................51

MECHANICAL INSTALLATION............................................................................................................51

ELECTRICAL INSTALLATION..............................................................................................................52

AIR FLOW ADJUSTMENTS ...................................................................................................................53

RAPID ROLL®MODEL 570/670 INSTALLATION CHECKLIST.............................................................55