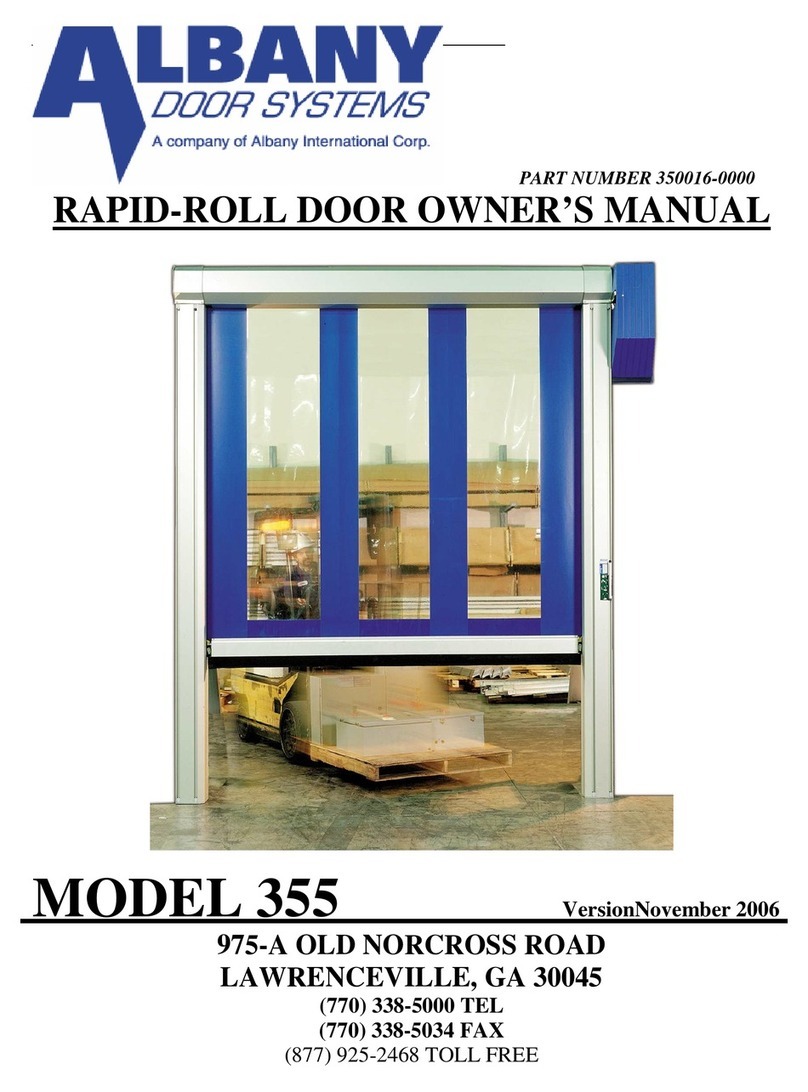

3 Manual #6410T0021 1/5/2011

DOOR INSTALLATION

Lock-Out Tag-out all electrical power supplied to the

door before making any electrical installations or

connections. Also Lock-out Tag-out any equipment

near the installation site if that equipment may be

inadvertently operated into the area used to assem-

ble and install the door. Failure to properly de-

energize electrical circuits and disable equipment

during installation and/or maintenance could result in

death or serious injury.

Improper installation of anchoring devices or installa-

tion into aged or unsound concrete block, or other

wall material may result in premature wear, product

failure, property damage, or serious personal injury.

Use proper lifting equipment and techniques. Prop-

erly secure all loads. Failure to properly secure all

lifting loads could result in death or serious injury.

Secure the work area so that persons not

working directly on the installation do not

enter the work area.

TOOLS AND MATERIALS REQUIRED

Personnel

Two people to install the door

One person qualified to operate forklift, hoist,

or crane

One electrician to install and connect the

control panel and all electrical wiring

Tools

Assorted wrenches

Tape measure

Carpenter’s square

Level (4ft minimum recommended)

Lifting device (fork lift, hoist, crane)

Lifting Straps

2 ladders or personnel lifts (tall enough to

reach above the door head)

Other tools as needed for the type of anchor-

ing chosen

Materials

Anchors appropriate for the type of wall the

door and accessories are to be installed

onto. Albany Doors recommends through-

bolting doors whenever possible.

Wire as specified on the electrical schematic

Electrical supplies needed to comply with all

regulating body electrical codes and stan-

dards.

See applicable control manual with door.

SITE PREPARATION

Electrical Supply

Qualified electrician must make all electrical

mountings and connections in accordance with

all applicable regulating body(s) electrical codes

and standards. . See applicable electrical manual

for specifications and wiring instructions..

Door Opening

1. Are the door jambs and support wall structur-

ally sound providing a flat surface for the side

columns to mount against?

2. Check the width and height of the door open-

ing and verify the measurements against the

dimensions of the door.

3. Is the opening square? Plumb?

4. Is the floor level across the opening?

Make all necessary structural repairs and improvements

to provide a “yes” answer to each of the questions above.

UNPACKING AND PREPARING

1. Inspect and unpack the components. Report any

damage immediately to Albany at (262) 268-9885.

Refer to the serial number tag located on the right

door column.

2. DO NOT cut the banding which holds the door in a

roll until instructed to do so in a later procedure.

The door panel and roll assembly could be damaged.

Use evenly spaced padded supports to prevent rips,

tears, or bending of the roll assembly. Failure to pro-

tect the roll assembly could result in damage to the

door.